1. Our weld fittings are designed to provide a reliable and secure connection for various applications. Made from stainless steel, these fittings offer excellent durability and resistance to corrosion, ensuring long-lasting performance.

2. These weld fittings are manufactured using casting techniques, ensuring precise dimensions and superior strength. The wall thickness of Sch5s enhances their robustness, making them suitable for demanding environments.

3. Our weld fittings have received certifications such as ASME, ANSI, DIN, JIS, BS, GB, GS, KS , and API, guaranteeing their compliance with industry standards. This ensures their suitability for diverse industrial applications.

4. The weld fittings feature a stylish silver color that adds a professional and modern touch to your installations. The visually appealing finish enhances the overall aesthetics of your system.

5. Our weld fittings are available in different thread sizes, including Taper, Parallel, or Mini thread options, and a range of tube diameters from 4mm to 12mm. They can withstand operating pressures up to 145 PSI (0 - 10 Bar) and temperatures ranging from 0° to +60° C. Additionally, they can handle vacuum levels of -14.5 PSI (-1 Bar).

|

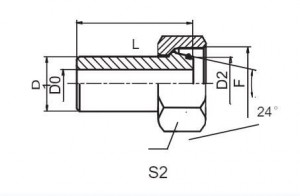

PART NO. |

THREAD |

TUBE SIZE |

DIMENSIONS |

MPa |

|||

|

f |

D1xt |

L |

D0 |

D2 |

S2 |

||

|

S2WC-6X1.5 |

M12X1.5 |

6X1.5 |

30 |

2.5 |

6 |

14 |

25L |

|

S2WC-8X2.0 |

M14X1.5 |

8X2.0 |

30 |

4 |

8 |

17 |

|

|

S2WC-10X2.0 |

M16X1.5 |

10X2.0 |

31 |

6 |

10 |

19 |

|

|

S2WC-12X2.0 |

M18X1.5 |

12X2.0 |

31 |

7.5 |

12 |

22 |

|

|

S2WC-15X2.0 |

M22X1.5 |

15X2.0 |

35 |

10 |

15 |

27 |

|

|

S2WC-18X2.0 |

M26X1.5 |

18X2.0 |

35 |

13 |

18 |

32 |

|

|

S2WC-22X2.0 |

M30X2 |

22X2.0 |

35 |

17 |

22 |

36 |

16 L |

|

S2WC-28X2.5 |

M36X2 |

28X2.5 |

41 |

23 |

28 |

41 |

|

|

S2WC-35X3.0 |

M45X2 |

35X3.0 |

48 |

29 |

35 |

50 |

|

|

S2WC-42X3.0 |

M52X2 |

42X3.0 |

50.5 |

36 |

42 |

60 |

|

|

S2WD-6X1.5 |

M14X1.5 |

6X1.5 |

28.5 |

2.5 |

6 |

17 |

63 S |

|

S2WD-8X2.0 |

M16X1.5 |

8X2.0 |

29 |

4 |

8 |

19 |

|

|

S2WD-10X1.0 |

M18X1.5 |

10X1.0 |

32 |

6.5 |

10 |

22 |

|

|

S2WD-10X1.5 |

M18X1.5 |

10X1.5 |

32 |

6.5 |

10 |

22 |

|

|

S2WD-10X2.0 |

M18X1.5 |

10X2.0 |

32 |

6 |

10 |

22 |

|

|

S2WD-12X1.5 |

M20X1.5 |

12X1.5 |

32.5 |

8 |

12 |

27 |

|

|

S2WD-12X2.0 |

M20X1.5 |

12X2.0 |

32.5 |

8 |

12 |

27 |

|

|

S2WD-12X2.5 |

M20X1.5 |

12X2.5 |

32.5 |

7 |

12 |

27 |

|

|

S2WD-16X1.5 |

M24X1.5 |

16X1.5 |

39 |

13 |

16 |

30 |

40 S |

|

S2WD-16X2.0 |

M24X1.5 |

16X2.0 |

39 |

12 |

16 |

30 |

|

|

S2WD-16X2.5 |

M24X1.5 |

16X2.5 |

39 |

1 1 |

16 |

30 |

|

|

S2WD-16X3.0 |

M24X1.5 |

16X3.0 |

39 |

10 |

16 |

30 |

|

|

S2WD-20X2.0 |

M30X2 |

20X2.0 |

43 |

15 |

20 |

36 |

|

|

S2WD-20X2.5 |

M30X2 |

20X2.5 |

43 |

15 |

20 |

36 |

|

|

S2WD-20X3.0 |

M30X2 |

20X3.0 |

43 |

14 |

20 |

36 |

|

|

S2WD-20X4.0 |

M30X2 |

20X4.0 |

43 |

12 |

20 |

36 |

|

|

S2WD-25X2.5 |

M36X2 |

25X2.5 |

50 |

20 |

25 |

46 |

|

|

S2WD-25X3.0 |

M36X2 |

25X3.0 |

50 |

19 |

25 |

46 |

|

|

S2WD-25X4.0 |

M36X2 |

25X4.0 |

50 |

17 |

25 |

46 |

|

|

S2WD-25X5.0 |

M36X2 |

25X5.0 |

50 |

15 |

25 |

46 |

|

|

S2WD-30X3.0 |

M42X2 |

30X3.0 |

52 |

24 |

30 |

50 |

25 S |

|

S2WD-30X4.0 |

M42X2 |

30X4.0 |

52 |

22 |

30 |

50 |

|

|

S2WD-30X5.0 |

M42X2 |

30X5.0 |

52 |

20 |

30 |

50 |

|

|

S2WD-30X6.0 |

M42X2 |

30X6.0 |

52 |

18 |

30 |

50 |

|

|

S2WD-38X4.0 |

M52X2 |

38X4.0 |

56.5 |

30 |

38 |

60 |

|

|

S2WD-38X5.0 |

M52X2 |

38X5.0 |

56.5 |

28 |

38 |

60 |

|

|

S2WD-38X6.0 |

M52X2 |

38X6.0 |

56.5 |

26 |

38 |

60 |

|

|

S2WD-38X7.0 |

M52X2 |

38X7.0 |

56.5 |

24 |

38 |

60 |

|

Our high-quality weld fittings, specifically designed to deliver reliable and secure connections for a wide range of applications. Crafted from premium stainless steel, these fittings exhibit exceptional durability and exceptional resistance to corrosion, ensuring long-lasting performance even in challenging environments.

Manufactured using advanced casting techniques, our weld fittings guarantee precise dimensions and superior strength, meeting the highest standards of quality. The wall thickness of Sch5s adds an extra layer of robustness, making these fittings ideal for demanding industrial settings where durability is paramount.

To further assure our customers of their reliability, our weld fittings have obtained certifications from renowned organizations such as ASME, ANSI, DIN, JIS, BS, GB, GS, KS, and API. These certifications confirm their adherence to industry standards, validating their suitability for various industrial applications.

In addition to their exceptional functionality, our weld fittings boast an elegant silver color that adds a touch of professionalism and modernity to any installation. The visually appealing finish not only enhances the overall aesthetics of your system but also reflects our commitment to delivering products of the highest quality.

We understand the importance of versatility, which is why our weld fittings are available in different thread sizes, including Taper, Parallel, or Mini thread options, catering to diverse installation requirements. With a range of tube diameters from 4mm to 12mm, you can find the perfect fit for your specific needs.

These weld fittings have been rigorously tested and proven capable of withstanding operating pressures up to 145 PSI (0 - 10 Bar) and temperatures ranging from 0° to +60° C, making them highly reliable in various working conditions. Moreover, they can handle vacuum levels of -14.5 PSI (-1 Bar), ensuring optimal performance in demanding environments.

Choose Sannke as your trusted partner for hydraulic fittings. We are renowned for being the best hydraulic fitting factory, known for our commitment to quality and customer satisfaction. Contact us today to discover the perfect weld fittings for your applications and experience the excellence that sets us apart.

-

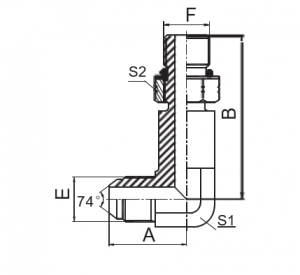

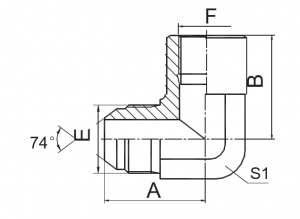

90° JIC Male / Long SAE O-Ring Boss L Series | ...

-

JIC Male 74° Cone / BSP Male Captive Seal | Cus...

-

90° JIC Male 74° Cone / BSP Female Adapters | P...

-

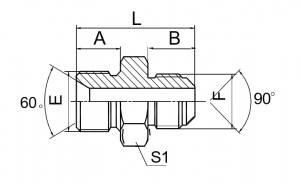

BSP Male 60° Seat / SAE Male 90° Cone Fitting |...

-

90° Elbow Metric Male Adjustable Stud End L-Ser...

-

ISO 6149-3 / NPT Female | Reliable Hydraulic Fi...