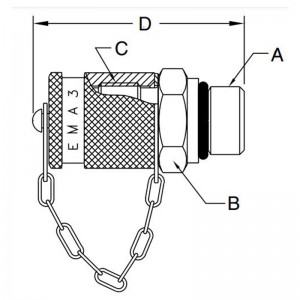

1. Our SAE Straight Thread Test Port Fitting is equipped with EMA couplings, which make it easy to connect Sensor Control equipment or mechanical gauges for diagnostic purposes.

2. Typically permanently plumbed into a fluid system at locations where pressure measurements are required for maintenance or testing.

3. Come with an integral pressure cap that protects the test point from damage and prevents contamination of the fluid system, ensuring that the system stays clean and free from debris.

4. Designed with a proven twist-to-connect mechanism that allows them to be connected even when the system is in operation and the test points are pressurized, providing a safe and hassle-free solution for your diagnostic needs.

5. Feature a compact design and optional high-pressure hose assemblies that offer extra flexibility for the location of system test points, making them ideal for a wide range of applications that require compact high-pressure connections and limited flow rates.

| PART# | PORT THREAD SIZE | WRENCH FLATS | INTERFACE THREAD SIZE | OVERALL LENGTH | WEIGHT |

| SEMA3/7/16-20UNF-2A* | 7/16-20UNF-2A | 17 | M16X2.0 | 1.88 | 0.15 |

| SEMA3/9/16-18UNF-2A* | 9/16-18UNF-2A | 19 | M16X2.0 | 1.88 | 0.17 |

* O-Ring seal on port

Our SAE Straight Thread Test Port Fitting is designed to facilitate easy diagnostic connections for SensoControl equipment or mechanical gauges. With EMA couplings, this fitting allows for seamless connection and integration of diagnostic tools for accurate and efficient testing.

Typically permanently plumbed into fluid systems, our test port fitting is strategically located at points where pressure measurements are crucial for maintenance or testing purposes. This positioning ensures convenient access to critical data, enabling effective monitoring and troubleshooting.

To safeguard the integrity of your fluid system, our test port fitting is equipped with an integral pressure cap. This protective cap prevents damage to the test point and effectively prevents contamination, maintaining the cleanliness and reliability of the system. You can trust our fitting to keep your fluid system in optimal condition.

With a proven twist-to-connect design, our fitting allows for quick and secure connections. Even when the system is in operation and the test points are pressurized, you can effortlessly connect and disconnect the diagnostic equipment. This feature enhances convenience and minimizes downtime during diagnostic procedures.

The compact design of our fitting offers flexibility in locating system test points. Additionally, optional high-pressure hose assemblies provide further versatility. These features make our test port fitting suitable for a wide range of applications that require compact high-pressure connections and limited flow rates. Whether it’s in industrial settings or other diagnostic applications, our fitting delivers reliable performance.

Sannke takes pride in being recognized as a trusted hydraulic fitting factory. We are committed to manufacturing high-quality products that meet the highest industry standards. Contact us today to discover more about our hydraulic fittings and how they can enhance your diagnostic processes.