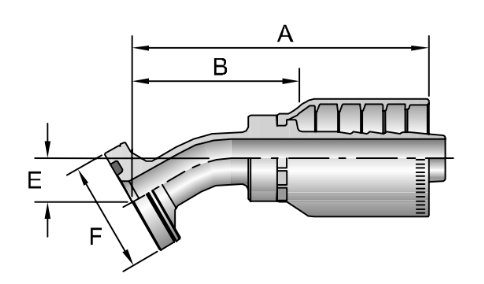

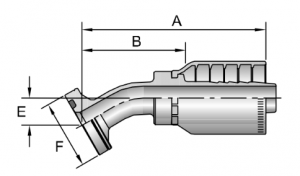

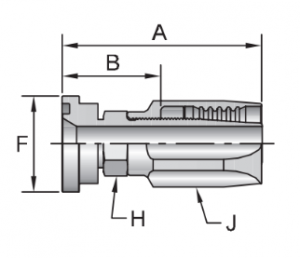

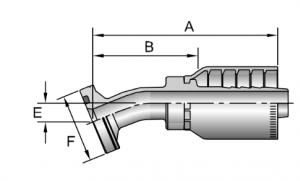

1. Superior Crimp Quality: SAE Code 62 Flange Head – 30° Elbow ensures a top-tier crimp coupling, prioritizing safety, security, and leak-free performance for a productive work environment.

2. NO-Skive Technology: Experience a tough, compact, and reliable alternative with our NO-Skive crimp coupling, designed to bite through hose covers for increased durability and reduced assembly time.

3. Shorter Crimp Shell: The aggressive bite allows for a shorter crimp shell, creating a longer live length on assemblies and enhancing bending capabilities in your hydraulic system.

4. Advanced Plating Process: All metal couplings undergo a cutting-edge plating process, surpassing SAE J514 corrosion protection standards, preventing premature breakdown and corrosion commonly seen in lower-grade fittings.

5. Hexavalent Chromium-Free: The plating process is completely hexavalent chromium-free, providing an environmentally friendly solution while ensuring robust protection against corrosion for your hydraulic fittings.

|

PART #

|

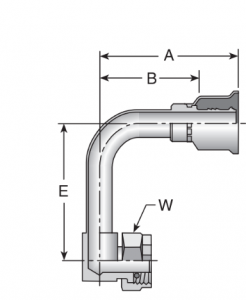

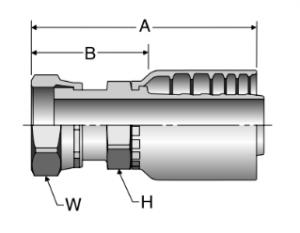

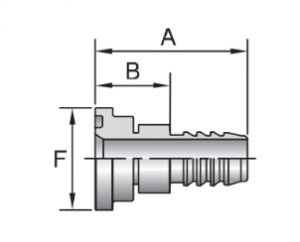

FLANGE | HOSE ID | A | E | F | B | |||

| inch | inch | inch | mm | inch | mm | inch | inch | mm | |

| S16E78-20-20 | 1-1/4 | 1-1/4 | 6.71 | 170 | 0.87 | twenty two | 2-1/8 | 4.32 | 110 |

| S16E78-24-24 | 1-1/2 | 1-1/2 | 7.1 | 180 | 1.12 | 28 | 2-1/2 | 4.89 | 124 |

Elevate your hydraulic system with the SAE Code 62 Flange Head – 30° Elbow, setting the standard for top-tier crimp couplings that prioritize safety, security, and leak-free performance. This robust hydraulic fitting, a hallmark of commitment to quality, offers a superior NO-Skive crimp coupling, known for its toughness, compact design, and reliability.

Experience the innovation of NO-Skive technology, where the teeth inside crimp shells bite through the hose cover, enhancing durability and reducing assembly time. This aggressive bite not only eliminates the need for skiving but also allows for a shorter crimp shell, creating a longer live length on assemblies and boosting bending capabilities in your hydraulic system.

Ensure the longevity of your hydraulic fittings with advanced plating process, surpassing SAE J514 corrosion protection standards. This cutting-edge process prevents premature breakdown and corrosion commonly observed in lower-grade fittings, promoting a reliable and efficient hydraulic system.

Taking a step further towards environmental responsibility, Plating process is completely hexavalent chromium-free. This not only provides a sustainable solution but also ensures robust protection against corrosion, setting Falcon apart in terms of both quality and eco-friendliness.

Experience the pinnacle of crimp quality with Sannke, recognized as the best hydraulic fitting factory. Contact us for hydraulic solutions that deliver on durability, reliability, and environmental consciousness.