1. Engineered for precise fluid system connections. Its 74° seat ensures a snug fit, promoting optimal fluid flow control and secure operations.

2. Choose from a range of protective finishes including zinc-plated, Zn-Ni-plated, Cr3, and Cr6 plated.

3. Tailor the fitting to your specific application with alternative materials like stainless steel, carbon steel, and brass.

4. Its meticulously designed seat ensures a secure and leak-proof joint, making it an ideal choice for critical fluid applications.

5. From a variety of finish options to material alternatives, this fitting meets stringent quality standards.

|

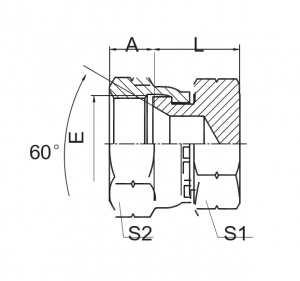

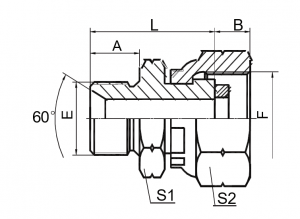

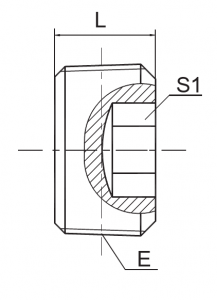

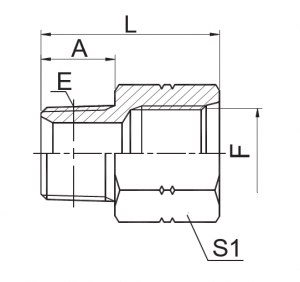

PART NO.

|

THREAD | O-RING | DIMENSIONS | |||||

| E | F | E | A | B | L | S1 | S2 | |

| S2FJ-04 | 9/16X18 | 7/16″X20 | O011 | 10 | 9 | 24 | 17 | 17 |

| S2FJ-04-06 | 9/16X18 | 9/16X18 | O011 | 10 | 10.5 | 25 | 17 | 19 |

| S2FJ-06-04 | 11/16″X16 | 7/16″X20 | O012 | 11.2 | 9 | 25.5 | 19 | 17 |

| S2FJ-06 | 11/16″X16 | 9/16″X18 | O012 | 11.2 | 10.5 | 26 | 19 | 19 |

| S2FJ-06-08 | 11/16″X16 | 3/4″X16 | O012 | 11.2 | 10.5 | 30 | 19 | 24 |

| S2FJ-08-06 | 13/16″X16 | 9/16″X18 | O014 | 13 | 10.5 | 28 | 22 | 19 |

| S2FJ-08 | 13/16″X16 | 3/4″X16 | O014 | 13 | 10.5 | 31.5 | 22 | 24 |

| S2FJ-08-10 | 13/16″X16 | 7/8″X14 | O014 | 13 | 12 | 34 | 22 | 27 |

| S2FJ-10-08 | 1″X14 | 3/4″X16 | O016 | 15.5 | 10.5 | 36 | 27 | 24 |

| S2FJ-10 | 1″X14 | 7/8″X14 | O016 | 15.5 | 12 | 36.5 | 27 | 27 |

| S2FJ-10-12 | 1″X14 | 1.1/16″X12 | O016 | 15.5 | 15 | 39 | 27 | 32 |

| S2FJ-12-10 | 1.3/16″X12 | 7/8″X14 | O018 | 17 | 12 | 39 | 32 | 27 |

| S2FJ-12 | 1.3/16″X12 | 1.1/16″X12 | O018 | 17 | 15 | 40.5 | 32 | 32 |

| S2FJ-12-16 | 1.3/16″X12 | 1.5/16″X12 | O018 | 17 | 16 | 40.5 | 32 | 41 |

| S2FJ-16-12 | 1.7/16″X12 | 1.1/16″X12 | O021 | 17.5 | 15 | 41 | 38 | 32 |

| S2FJ-16 | 1.7/16″X12 | 1.5/16″X12 | O021 | 17.5 | 16 | 41 | 38 | 41 |

| S2FJ-20 | 1.11/16″X12 | 1.5/8″X12 | O025 | 17.5 | 17 | 47.5 | 46 | 50 |

| S2FJ-24 | 2″X12 | 1.7/8″X12 | O029 | 17.5 | 20 | 50 | 55 | 55 |

An exceptional fluid system connection solution: the ORFS Male / JIC Female 74° Seat fitting. Engineered with precision in mind, this fitting is a testament to the art of fluid control. Its innovative design, featuring a 74° seat, guarantees a perfectly snug fit. This, in turn, translates to impeccable fluid flow control and unwavering operational security.

Customization is key, and we understand that. That’s why our fitting offers a wide array of protective finishes, including zinc-plated, Zn-Ni-plated, Cr3, and Cr6 plated options. You have the freedom to select the finish that aligns with your requirements, ensuring both aesthetic appeal and durability.

Not stopping at finishes, our fitting goes further by allowing you to tailor it to your specific application. With alternative materials like stainless steel, carbon steel, and brass, the versatility of this fitting is unmatched. Whatever your industry or project demands, rest assured, we have the right material to match.

Highlighting our commitment to excellence, the meticulously designed seat of this fitting guarantees more than just a joint. It ensures a secure and leak-proof connection, particularly crucial for critical fluid applications. With this fitting in place, you can trust in its reliability and efficiency.

Meeting stringent quality standards is not just a claim; it’s our guarantee. From the diverse finish options to the spectrum of material alternatives, each aspect of this fitting reflects our dedication to delivering excellence.

When you choose the ORFS Male / JIC Female 74° Seat fitting, you’re choosing a solution that marries innovation, customization, and reliability. And remember, Sannke stands as a beacon in the realm of hydraulic fitting manufacturing. For the best hydraulic fitting factory experience, reach out to us today. Your fluid control needs deserve nothing less than the finest, and that’s what we’re here to deliver.

-

90° Elbow NPT Male / BSP Female 60° Cone Connec...

-

GAS FEMALE 60°SEAT PLUG | Versatile Compatibility

-

90° Elbow Reducer Tube Adapter With Swivel Nut ...

-

BSP Male Double Use for 60° Cone Seat or Bonded...

-

BSPT Male Hollow Hex | Corrosion-Resistant Carb...

-

NPT Male / SAE Female ISO 11926-1 | Corrosion-R...