Hydraulic hose fittings are crucial components in hydraulic systems, ensuring the safe and efficient transfer of fluid power. They play a vital role in connecting hoses to various hydraulic components, such as pumps, valves, and cylinders. Understanding the different types, components, and benefits of hydraulic hose fittings is essential for anyone working with hydraulic systems.

Types of Hydraulic Hose Fittings

Crimped Fittings:

Crimped fittings are commonly used in hydraulic systems, offering a secure and leak-free connection. These fittings are permanently attached to the hose using a crimping machine. They provide excellent strength and durability, making them suitable for high-pressure application s. are widely used in industries such as construction, agriculture, and manufacturing.

Reusable Fittings:

Reusable fittings are designed to be easily installed and removed from the hose, providing flexibility for repairs and maintenance. They consist of two parts: the fitting body and the reusable hose end. These fittings are ideal for low to medium pressure applications and are commonly used in industries such as automotive and aerospace.

Push-On Fittings:

Push-on fittings are simple and quick to install, requiring no special tools. They have barbed ends that grip the hose when pushed onto it, creating a secure connection. These fittings are commonly used in low-pressure applications, such as pneumatic systems and air tools.

Components of Hydraulic Hose Fittings

Hose Ends

Hose ends are the connection points of the hydraulic hose. They come in male and female variations, allowing hoses to be connected to different components. Hose ends have specific thread types and sizes that ensure compatibility with other fittings and components.

Ferrules

Ferrules are metal sleeves that are crimped onto the hose ends to secure them in place. They provide structural integrity and prevent the hose from detaching under pressure. Ferrules come in various types, such as one-piece and two-piece, and are typically made of materials like steel or brass.

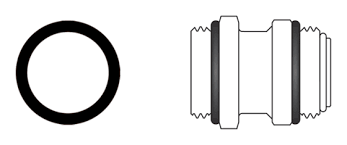

O-Rings

O-rings are small, round seals used to create a tight and leak-free connection between the hose and fittings. They are commonly made of materials like nitrogen rubber or Viton. O-rings come in different sizes and play a crucial role in maintaining the integrity of the hydraulic system.

Key Considerations for Selecting Hydraulic Hose Fittings

Pressure Rating and Compatibility:

Selecting the appropriate hydraulic hose fittings requires considering the system’s operating pressure and ensuring compatibility with the fluid being conveyed. Choosing fittings with the correct pressure rating is vital to avoid leaks and ensure optimal performance.

Hose Size and Diameter:

The size and diameter of the hydraulic hose are critical factors in selecting the right fittings. Fittings should match the hose’s inner diameter to ensure a proper fit and secure connection.

Temperature and Environmental Considerations:

Hydraulic systems can operate under extreme temperature conditions or in harsh environments. It is essential to choose fittings that can withstand the temperature range and environmental conditions to maintain the system’s reliability.

Installation and Maintenance of Hydraulic Hose Fittings

Proper Installation Techniques:

Proper installation techniques are critical to ensure the fittings are correctly attached to the hose. This includes selecting the appropriate crimping equipment, following manufacturer guidelines, and inspecting the fittings for any defects before installation.

Inspections and Preventive Maintenance:

Regular inspections and preventive maintenance are essential to identify any signs of wear, damage, or leaks in the hydraulic hose fittings. Timely maintenance and replacement of worn-out fittings can prevent costly system failures and downtime.

Benefits of Using Proper Hydraulic Hose Fittings

Leakage Prevention and Improved Efficiency:

Using the right hydraulic hose fittings eliminates leaks, ensuring efficient fluid transfer and preventing waste. This leads to improved system efficiency and reduced energy consumption.

Enhanced Safety and Reliability:

Properly fitted hydraulic hose fittings enhance the safety and reliability of the system. They prevent hose detachment and minimize the risk of accidents, ensuring smooth operation and reducing downtime.

Cost Savings in the Long Run:

Investing in high-quality hydraulic hose fittings may initially incur a higher cost but can result in significant cost savings in the long run. Reliable fittings reduce the need for frequent replacements and repairs, minimizing maintenance costs.

Common Challenges and Troubleshooting Tips

Identifying and Resolving Leaks:

Leaks in hydraulic hose fittings can lead to system inefficiency and potential hazards. Regular inspections, proper torque settings, and prompt repair of leaks are crucial to maintain system integrity.

Dealing with Improper Fitting Installation:

Improper fitting installation can result in leaks or premature failure. Following manufacturer guidelines and using the correct installation techniques ensure a proper and secure fit.

Addressing Compatibility Issues:

Compatibility issues between fittings, hoses, and components can lead to leaks and system malfunctions. Ensuring proper compatibility through careful selection of fittings helps avoid such problems.

Wrap Up

Understanding hydraulic hose fittings is essential for maintaining efficient and reliable hydraulic systems. Choosing the right type of fitting, considering factors like pressure rating and compatibility, and following proper installation and maintenance practices are key to achieving optimal performance. By investing in quality fittings and adopting preventive measures, businesses can increase productivity, improve safety, and reduce long-term costs in their hydraulic systems.

Post time: Jun-02-2023