Have you ever wondered how power is transferred from one rotating shaft to another, especially when they’re not perfectly aligned? That’s where a universal joint comes in. Essentially, it’s a mechanical component that allows for smooth power transmission even when there’s an angle between the input and output shafts.

Universal joints are all around us. From the car you drive to the industrial machinery that powers our world, these unassuming components play a crucial role. Today, we’re going to break down how they work and why they’re so important.

What is a Universal Joint?

Image source: https://www.researchgate.net

Have you ever wondered how power is transferred from one rotating shaft to another, especially when they’re not perfectly aligned? That’s where a universal joint comes in. Essentially, it’s a mechanical component that allows for smooth power transmission even when there’s an angle between the input and output shafts.

Universal joints are all around us. From the car you drive to the industrial machinery that powers our world, these unassuming components play a crucial role. Today, we’re going to break down how they work and why they’re so important.

Understanding How a Universal Joint Works

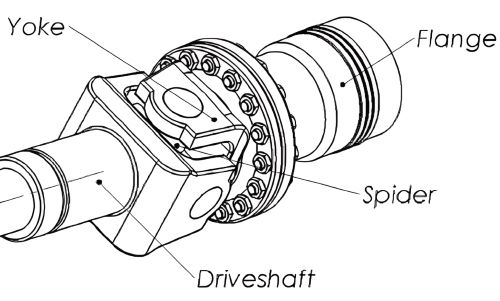

A universal joint is made up of three main parts: the cross, the yoke, and the bearings. The cross is a central piece with two pairs of pins that intersect at right angles. Each pair of pins is connected to a yoke, which is attached to a rotating shaft. The bearings enable the cross to rotate smoothly within the yokes.

As one shaft rotates, the cross moves up and down within the yokes. This movement compensates for the angle between the shafts, ensuring that power is transmitted smoothly. It’s like a flexible bridge connecting two rotating elements.

Common Applications of Universal Joints

Universal joints are used in a variety of industries.

➡️ Automotive Industry:

Perhaps the most familiar use is in vehicles. The driveshaft that connects the transmission to the rear axle typically employs one or more universal joints to accommodate changes in the angle of the driveshaft as the vehicle goes over bumps.

➡️ Industrial Machinery:

From conveyors to mixers, universal joints are essential in transferring power efficiently in various industrial setups.

➡️ Other Applications:

You’ll also find universal joints in agriculture (farm equipment), construction (heavy machinery), and marine applications (boat propulsion).

Also, read these resources for more information on hydraulic adapters and fittings ⬇️⬇️⬇️

Compression Ferrule Hacks: Tips For Perfect Seals

Run Tee Vs Branch Tee Fittings: A Detailed Comparison

Benefits of Using Universal Joints

➡️ Flexibility: Universal joints can accommodate varying angles between shafts, making them adaptable to different applications.

➡️ Efficient Power Transmission: They transmit power smoothly, minimizing energy loss.

➡️ Durability: Well-designed universal joints are built to last, enduring harsh operating conditions.

Maintenance and Care of Universal Joints

While universal joints are robust, they do require some care to ensure optimal performance and longevity. Look out for signs of wear like excessive noise, vibration, or difficulty in turning. Regular inspection, lubrication, and replacement when necessary are crucial maintenance steps.

Conclusion

Universal joints are unsung heroes of the mechanical world. By understanding how they work and their importance, you gain a deeper appreciation for the engineering marvels that surround us.

Next time you’re driving or observing machinery in action, remember the humble universal joint and its role in making it all possible.

Post time: Aug-07-2024