Threaded connections are essential components in various industries, from construction to manufacturing. Understanding the typical pressure a thread can withstand is crucial for ensuring the safety, reliability, and longevity of these connections.

In this blog post, we will delve into the key factors that influence thread pressure, how to calculate and manage it effectively, and the potential consequences of exceeding pressure limits.

What is Thread Pressure?

Thread pressure refers to the force per unit area exerted on the mating surfaces of a threaded joint. It is a critical parameter that determines the strength and integrity of the connection.

How Pressure Affects Threaded Joints and Connections:

Excessive pressure can lead to thread deformation, stripping, or even failure. Conversely, insufficient pressure may result in leaks, loosening, or reduced joint strength.

Factors That Influence Typical Pressure on a Thread

Several factors can influence the typical pressure a thread can withstand:

➡️ Material Strength and Compatibility:

The materials used for the threaded components, as well as their compatibility, play a significant role in determining pressure tolerance. Stronger materials can generally withstand higher pressures.

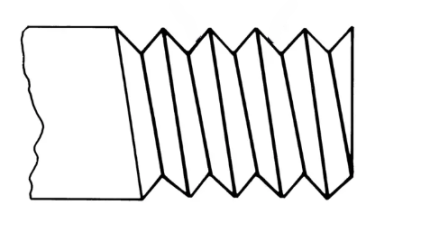

➡️ Thread Type and Design:

Tapered threads, such as NPT (National Pipe Thread), typically have higher pressure ratings than straight threads due to their self-sealing properties.

➡️ Environmental Conditions:

Temperature extremes and corrosive environments can weaken thread materials and reduce their pressure tolerance.

➡️ Vibration and Movement:

Repeated vibrations or movement can cause stress on threaded joints, potentially leading to fatigue and premature failure.

Understanding Thread Pressure Ratings

What are Pressure Ratings?

Thread pressure ratings are specified by manufacturers and industry standards and indicate the maximum pressure a thread can safely withstand under specific conditions.

How to Read and Interpret Thread Pressure Ratings:

Pressure ratings are usually expressed in units such as pounds per square inch (psi) or kilopascals (kPa). It’s essential to consult the appropriate standards or manufacturer’s specifications when selecting threads for a particular application.

Common Pressure Standards for Various Thread Types:

Some common thread standards and their associated pressure ratings include:

➡️ NPT (National Pipe Thread): Typically rated for higher pressures, especially in plumbing and piping applications.

➡️ BSP (British Standard Pipe Thread): Another common standard used in many countries.

➡️ Metric Threads: Offer a wide range of sizes and pressure ratings, suitable for various industrial applications.

Calculating Typical Pressure on a Thread

Essential Calculations: Stress, Load, and Force:

To calculate the typical pressure on a thread, you need to consider factors such as stress, load, and force. Stress is the force per unit area applied to a material, load is the total force acting on a threaded joint, and force is the push or pull exerted on the connection.

How to Use Pressure Formulas in Real-World Scenarios:

By using appropriate pressure formulas and considering the specific dimensions and materials of the threaded components, you can accurately calculate the pressure exerted on the joint. This information is vital for ensuring safe and reliable operation.

Common Mistakes to Avoid in Pressure Calculations:

It’s important to avoid common mistakes such as neglecting friction, assuming uniform pressure distribution, or using outdated or incorrect data.

Effects of Overpressure on a Thread

Signs of Overpressure – overpressure can manifest in various ways, including:

➡️ Leaking threads

➡️ Thread deformation or stripping

➡️ Excessive vibration or noise

➡️ Premature failure

Impact of Overpressure on Thread Safety and Durability:

Overpressure can significantly compromise the safety and durability of a threaded connection. It can lead to leaks, structural failure, and potential hazards.

Tips for Managing and Reducing Thread Pressure

➡️ Choosing the Right Thread Type for Your Application: Select thread types that are appropriate for the intended pressure and environmental conditions.

➡️ Using Thread Sealants and Lubricants to Prevent Leaks: Apply suitable thread sealants or lubricants to ensure proper sealing and reduce friction.

➡️ Proper Installation Techniques for Pressure Management: Follow recommended installation procedures to avoid overtightening or misalignment, which can lead to excessive pressure.

Testing and Inspecting Pressure on a Thread

Methods for Testing Thread Pressure Limits:

Various methods can be used to test the pressure limits of threaded connections, such as hydraulic testing, ultrasonic testing, or visual inspections.

Key Inspection Points for Threaded Joints Under Pressure:

Regularly inspect threaded joints for signs of wear, corrosion, or damage, especially in high-pressure applications.

Recommended Testing Tools for Accurate Measurements:

Use appropriate testing tools, such as pressure gauges, torque wrenches, or specialized inspection equipment, to ensure accurate measurements and assessments.

Troubleshooting Common Pressure Issues in Threaded Connections

Identifying Pressure Leaks and Weak Points:

If you encounter pressure leaks or other issues, carefully inspect the threaded connection to identify the root cause.

Addressing Thread Deformation and Damage:

If thread deformation or damage is evident, take appropriate measures to repair or replace the affected components.

When to Replace vs. Repair: Making the Right Call:

Determine whether it’s more cost-effective and safe to repair or replace a damaged threaded connection.

Best Practices for Ensuring Threaded Connection Safety

➡️ Guidelines for Pressure Handling and Monitoring:

Establish clear guidelines for handling and monitoring pressure in threaded connections, especially in critical applications.

➡️ Maintaining Pressure Stability in High-Stress Applications:

Implement measures to maintain pressure stability in high-stress environments, such as using pressure regulators or vibration dampers.

➡️ Regular Maintenance and Inspections: Protecting Your Threads:

Conduct regular maintenance and inspections to identify and address potential issues before they escalate.

Conclusion

Understanding and managing typical pressure on a thread is essential for ensuring the safety, reliability, and longevity of threaded connections.

By considering factors such as material strength, thread type, environmental conditions, and proper installation techniques, you can effectively manage pressure and prevent failures.

Post time: Sep-27-2024