In today’s world, efficiency is paramount across various industries. It’s key for both industry types. It means making production lines faster and keeping machines in construction running well.

Enter swivel adapters. They are a simple but powerful tool. They can greatly improve efficiency and flexibility in these systems.

Understanding Swivel Adapters

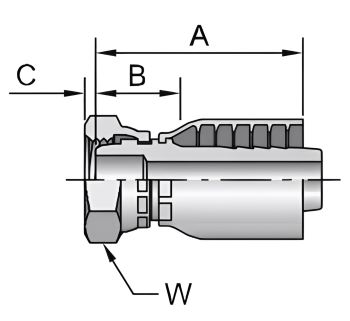

A swivel adapter is a versatile fitting featuring two key components:

Swivel Joint: This joint allows the adapter to rotate freely around a central axis, providing flexibility in connecting pipes or hoses.

Male/Female Threads: Swivel adapters typically have male threads on one end and female threads on the other, allowing them to screw onto pipes or hoses of different diameters.

The key functionality of a swivel adapter lies in its ability to introduce movement and flexibility into a piping system. Unlike rigid connections, swivel adapters allow for:

Rotation: The swivel joint enables the connected pipe or hose to rotate freely, reducing strain and preventing kinks or tangles.

Easier Installation and Maintenance: By allowing for some movement, swivel adapters can make installation and maintenance of fluid transfer systems much easier, especially in tight spaces.

Essential Techniques for Maximizing Efficiency with Swivel Adapters

To reap the full benefits of swivel adapters, proper selection and use are crucial. Here are some essential techniques:

1. Selecting the Right Adapter:

Size: Choose an adapter with thread sizes that match the pipes or hoses you’ll be connecting.

Pressure Rating: Ensure the adapter’s pressure rating is sufficient for the application. For high-pressure systems, consider adapters specifically designed for those conditions.

Material: Select a material compatible with the type of fluid being transferred (e.g., brass for water lines, stainless steel for corrosive fluids).

2. Proper Installation:

Clean Threads: Ensure the threads on the adapter and the pipes or hoses are clean and free of debris for a secure connection.

Tightening: Use appropriate wrenches to tighten the adapter securely, but avoid over tightening, which can damage the threads or adapter.

Compatible Components: Use compatible components like washers or gaskets (if required) to ensure a leak-proof seal.

3. Maintaining Swivel Functionality:

Lubrication (if applicable): Some swivel adapters, particularly those used in industrial settings, may benefit from occasional lubrication to maintain smooth swiveling action. Consult the manufacturer’s recommendations for specific lubrication details.

Avoiding Excessive Strain: While swivel adapters provide flexibility, avoid putting excessive strain on the joint, as this can damage it over time.

4. Utilizing Space Effectively:

Swivel adapters can be lifesavers in situations with limited space. They can rotate. This allows some freedom in positioning pipes or hoses. It makes connections easier and reduces the need for complex bends or awkward configurations.

Here are the resources to improve your knowledge on hydraulic system and fittings ⬇️⬇️⬇️

Hex Bushing: Your Secret Weapon For Pipe Fitting Success

Harnessing The Potential Of Flared Pipe Fittings: Tips For Success

The Key To Efficiency: SAE 4 Port Essentials

Applications of Swivel Adapters

The benefits of swivel adapters extend across various industries:

Manufacturing: In factories, swivel adapters connect machinery to fluid lines, allowing for movement and adjustment during operation without stressing the pipes or hoses.

Construction Equipment: Hydraulic systems on excavators, loaders, and other heavy machinery often utilize swivel adapters to enable flexible connections that can withstand movement and pressure.

Automotive Industry: Car washes, lubrication equipment, and even some engine components benefit from the flexibility offered by swivel adapters in fluid transfer applications.

Plumbing Applications: Swivel adapters are commonly used in residential and commercial plumbing to connect faucets, showerheads, and other components, especially in tight spaces where maneuverability is limited.

Additional Considerations

It’s important to acknowledge that swivel adapters have limitations. For very high-pressure applications, use welded or flanged connections. They might be a better choice. Furthermore, leaks may result from faulty installation.

In some cases, alternative solutions like flexible hoses might be preferable. However, these situations need both flexibility and secure connections. Swivel adapters offer a valuable and efficient option.

Conclusion

Efficiency is key in any fluid transfer system. Swivel adapters reduce strain. They also prevent kinks and make installation simpler. They are a powerful tool for maximizing efficiency. Follow the key techniques above. Also, think about where they shine. Doing this will unlock swivel adapters’ full potential. It will ensure they work well in your fluid transfer systems.

Next time you’re working on a project that needs adaptable fluid transfer, consider the power of the humble swivel adapter. It can boost efficiency.

Post time: May-15-2024