Special hydraulic fittings are the unsung heroes of hydraulic systems, often overlooked but crucial for ensuring efficient and reliable operations. In this article, we will dive deep into the world of special hydraulic fittings, exploring their types, advantages, applications, and essential considerations when selecting and maintaining them.

So, let's get started and unravel the mysteries behind these essential components that keep hydraulic systems running smoothly.

What are Special Hydraulic Fittings?

Special hydraulic fittings, as the name suggests, are fittings designed to cater to specific requirements in hydraulic systems. While standard fittings serve well in general applications, special fittings excel in addressing unique challenges, such as extreme pressure, temperature, or material compatibility. These fittings are tailored for particular purposes, ensuring leak-free connections and optimized performance in demanding industries.

Types of Special Hydraulic Fittings

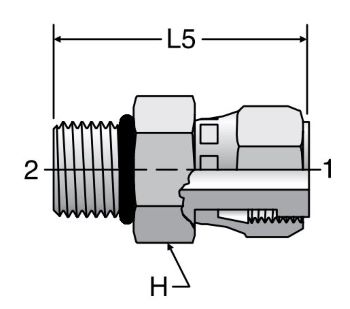

Hydraulic Swivel Fittings

A hydraulic swivel fitting serves as an ingenious apparatus, facilitating the rotational movement of the hose connection and coupling, allowing for a full 360-degree range of motion on its axis. This ingenious process meticulously averts any risk of tangling, twisting, kinking, or excessive bending of the hose, thereby remarkably reducing the potential for damage.

Furthermore, the hose swivels demonstrate their remarkable utility by adeptly compensating for abrupt alterations in hose length during pressurization, effectively mitigating system rigidity while adeptly absorbing and nullifying the impact of hydraulic shocks and surges within the line.

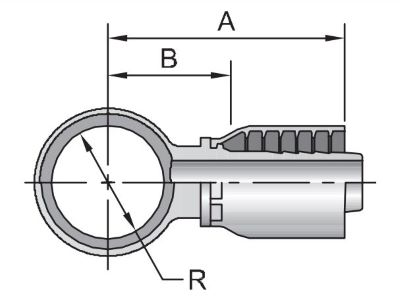

Reusable Hydraulic Hose Fittings

Utilized in diverse hydraulic systems, the reusable hydraulic hose fittings assume a vital role in the seamless repair of damaged fittings within pre-existing hydraulic hose assemblies, thereby significantly minimizing downtime. Referred to as field installable fittings, these ingenious components conveniently attach to compatible hydraulic hoses and are deftly secured in place with the assistance of a wrench.

Exhibiting remarkable versatility, these fittings prove well-suited for establishing robust connections between hoses in hydraulic systems as well as various general-purpose industrial applications, thereby effectively facilitating the conveyance of hydraulic fluid, air, and nonpotable water.

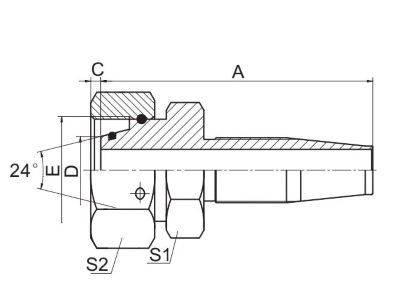

Hydraulic Banjo Fittings

Banjo fittings, meticulously engineered to complement hydraulic tubing in unison with hollow screws, manifest their excellence in Metric & Multistandard selection of steel banjo fittings available in metric sizes. Characterized by a hollow configuration on the long end, these fittings securely fasten to the terminus of a hydraulic tubing segment, while their open round end gracefully encloses the body of a suitably sized hollow screw. This ingenious union fosters optimal fluid flow as the hole in the hollow screw aligns flawlessly with the orifice within the open end of the banjo fitting, fostering the seamless passage of fluids throughout the entire assembly.

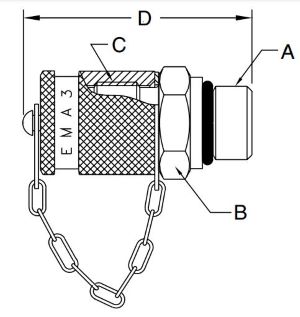

Hydraulic Test Port Fittings

Hydraulic test port fittings are components used in hydraulic systems to facilitate pressure testing, monitoring, and diagnostics. These are also known as test point fittings, test couplings, or test ports, providing access points in the hydraulic system where pressure gauges, transducers, or other testing equipment can be connected. These fittings are designed to temporarily tap into the hydraulic circuit without disrupting the normal operation of the system. This allows engineers, technicians, or maintenance personnel to measure system pressure, flow rate, temperature, and other parameters, and diagnose any problems or performance discrepancies.

Advantages of Using Special Hydraulic Fittings

Special hydraulic fittings offer several advantages that make them indispensable for specific applications:

Leak-Free Connections

Special fittings are designed to provide leak-free connections, ensuring the integrity of hydraulic systems even under high pressure.

Extreme Pressure and Temperature Resistance

These fittings can withstand extreme pressure and temperature conditions, making them suitable for harsh environments.

Enhanced Material Compatibility

Special fittings are engineered from materials compatible with various hydraulic fluids, preventing corrosion and degradation.

Optimized Performance

Designed for specific industry requirements, special fittings optimize the performance and efficiency of hydraulic systems.

Factors to Consider When Selecting Special Hydraulic Fittings

Selecting the right special hydraulic fittings for a specific application requires careful consideration of several factors:

Material Compatibility

Ensure that the fitting's material is compatible with the hydraulic fluid and environmental conditions to avoid corrosion and premature wear.

Pressure Ratings

Check the pressure rating of the fitting to ensure it can handle the maximum operating pressure of the hydraulic system.

Temperature Ratings

Consider the temperature range of the hydraulic system and choose fittings that can withstand those extremes.

Installation and Maintenance

Opt for fittings that are easy to install and maintain, especially in systems requiring frequent disassembly for maintenance purposes.

Applications of Special Hydraulic Fittings

Special hydraulic fittings find diverse applications across several industries, including:

Aerospace Industry

In the aerospace sector, special fittings play a vital role in hydraulic systems for aircraft landing gear, control surfaces, and flight control actuators.

Construction and Heavy Machinery

Construction equipment relies on special hydraulic fittings for precision control and efficient operation of hydraulic cylinders and other components.

Automotive Sector

In the automotive industry, special fittings are essential for power steering systems, hydraulic brake lines, and transmission systems.

Marine Applications

Special hydraulic fittings are used in marine hydraulic systems for steering control, stabilizers, and other critical functions.

Special Hydraulic Fittings vs. Standard Fittings

While standard hydraulic fittings have broad applications and are cost-effective, special fittings offer distinct advantages in specific situations. Standard fittings may not provide the same level of performance and reliability as special fittings under extreme conditions.

Best Practices for Installing and Maintaining Special Hydraulic Fittings

To ensure optimal performance and longevity of special hydraulic fittings, follow these best practices:

Use the Recommended Torque

Always use the recommended torque values when tightening fittings to avoid over-tightening or under-tightening.

Regular Inspection

Regularly inspect fittings for signs of wear, leaks, or damage and replace them promptly if necessary.

Proper Assembly Techniques

Use proper assembly techniques to avoid cross-threading or damaging the fittings during installation.

FAQs (Frequently Asked Questions)

Can special hydraulic fittings handle high-pressure applications?

Yes, special hydraulic fittings are specifically designed to withstand high-pressure environments, providing leak-free connections.

Are special fittings reusable?

In most cases, special fittings can be reused if they are in good condition and not damaged during disassembly.

Which industries commonly use special hydraulic fittings?

Industries such as aerospace, construction, automotive, and marine heavily rely on special hydraulic fittings for critical applications.

What are some common materials used in special hydraulic fittings?

Materials such as stainless steel, brass, and carbon steel are commonly used in the manufacturing of special fittings.

Are special hydraulic fittings suitable for extreme temperature conditions?

Yes, special fittings are engineered to withstand extreme temperature ranges, making them suitable for harsh environments.

Conclusion

Special hydraulic fittings play a vital role in hydraulic systems, offering optimized performance and reliable connections. Their unique designs and capabilities make them indispensable in various industries, ensuring the smooth operation of heavy machinery, vehicles, and equipment. When selecting special fittings, consider factors such as material compatibility, pressure and temperature ratings, and ease of installation.

By adhering to best practices during installation and maintenance, industries can enhance the efficiency and longevity of their hydraulic systems.

Post time: Aug-11-2023