In the intricate tapestry of hydraulic and pneumatic systems, precision and reliability are paramount. SAE J533, a standard that stands as a beacon in this domain, meticulously defines the specifications and requirements for flare-type fittings.

This article is a comprehensive exploration of SAE J533, aiming to demystify its complexities and elucidate its significance in the realm of fluid power.

Understanding SAE J533 Standards

At its core, SAE J533 delineates the standards for flare-type fittings, which are integral components in hydraulic and pneumatic systems. These fittings facilitate the seamless connection between tubes and hoses, ensuring the efficient transmission of fluids or gasses. The standard’s detailed specifications encompass aspects like dimensions, materials, and performance criteria, setting a benchmark for quality and functionality.

Design and Specifications

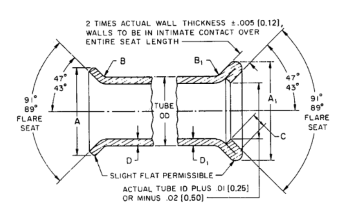

The design specified by SAE J533 is a testament to precision engineering. These flare-type fittings feature specific angles and dimensions, ensuring a snug fit and optimal performance. The meticulous detailing of threads and flare angles guarantees a leak-free connection, a vital characteristic for the integrity of hydraulic and pneumatic systems.

Single and Double 45-Deg Flares for Tubing

Dimension of Single and Double 45-Deg Flares for Tubing

Single and Double 37-Deg Flares for Tubing

Dimension of Single and Double 45-Deg Flares for Tubing

Material Selection

One of the cornerstones of SAE J533 is the careful selection of materials. Fittings complying with this standard are predominantly crafted from robust materials such as stainless steel, brass, or steel alloys. This careful material selection ensures the fittings can withstand varying pressures, resist corrosion, and endure harsh environmental conditions, enhancing their durability and longevity.

Applications Across Industries

SAE J533-compliant flare-type fittings find their applications across a myriad of industries. From automotive brake systems to aerospace hydraulics, these fittings play a pivotal role. Their versatility and reliability make them indispensable in industrial machinery, ensuring the seamless functioning of hydraulic and pneumatic systems in diverse contexts.

Quality Assurance and Compliance

Manufacturers adhere to SAE J533 with utmost diligence. Compliance with these standards ensures that the fittings meet the stringent quality criteria set forth by the industry. Rigorous testing, including pressure and leakage tests, guarantees the fittings’ performance under diverse conditions, instilling confidence in their users.

Conclusion

In the expansive landscape of hydraulic and pneumatic systems, SAE J533 stands tall as a guardian of quality and reliability. Its detailed standards, encompassing design, materials, and performance requirements, make it an indispensable reference for engineers and manufacturers. Understanding and implementing these standards is not merely a choice but a necessity for industries reliant on fluid power technology.

Post time: Nov-08-2023