Hydraulic systems form the backbone of various industrial applications, ensuring smooth operations across a multitude of sectors. At the heart of these systems lies a critical component: hydraulic connections. In this comprehensive guide, we delve into the intricate world of hydraulic connections, exploring the nuances of SAE J1926 standards and providing invaluable insights into their significance.

SAE J1926: Ensuring Precision and Compatibility

O-Ring Straight Thread Boss SAE J1926/1

SAE J1926, a standard set forth by the Society of Automotive Engineers, delineates the specifications for straight thread O-ring port connections in hydraulic systems. The standardization of thread profiles, particularly the 37-degree flared seat, is aimed at creating a leak-resistant, secure connection. By conforming to SAE J1926 standards, manufacturers ensure uniformity and compatibility across various hydraulic components.

The Anatomy of Hydraulic Connections

Straight Thread Design and O-ring Seals: Ensuring Reliability

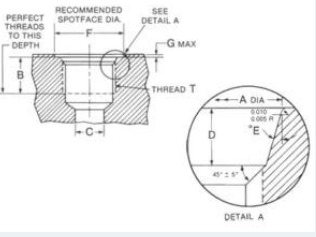

SAE J1926 mandates a straight thread design, characterized by its 37-degree flared seat. This design not only minimizes the risk of leaks but also guarantees a snug fit between components. Additionally, the incorporation of O-ring seals further fortifies the connection, preventing fluid seepage and enhancing the overall reliability of hydraulic systems.

Categorization of SAE J1926

Understanding SAE J1926-1: The Fundamental Thread Specifications

The foundational layer of hydraulic connections is their threads. SAE J1926-1 lays the groundwork by defining intricate thread specifications. Threads are critical as they ensure a secure, leak-free connection—a necessity when dealing with hydraulic systems that operate under high pressures. The standard provides precise requirements concerning thread forms, dimensions, tolerances, and design characteristics. Engineers and manufacturers refer to these specifications to create hydraulic fittings that align perfectly, establishing a secure connection capable of withstanding the high pressures inherent in hydraulic systems.

Thread engagement length is another crucial aspect covered by SAE J1926-1. It determines the effective thread engagement necessary for a robust connection. Proper thread engagement guarantees the fitting will endure the pressures and forces experienced during hydraulic operations. This standard guides in determining the right engagement length for various applications, contributing to the safety and efficiency of hydraulic connections.

Decoding SAE J1926-2: Delving into Port Connection Styles

The heart of hydraulic connections lies in their ports. SAE J1926-2 focuses on port connections and their diverse styles. The standard addresses various port design options, offering manufacturers and engineers a guideline for choosing the right port style based on the system’s requirements.

Ports can be either adjustable or non-adjustable, each offering distinct advantages and considerations. This standard ensures that the chosen port design aligns with the system’s needs, contributing to the overall efficiency and reliability of the hydraulic system.

Unveiling SAE J1926-3: Performance Testing for Hydraulic Connectors

While specifications are crucial, testing and validating the performance of hydraulic connectors is equally vital. SAE J1926-3 sets the performance and testing requirements for hydraulic connectors. This standard focuses on ensuring that the connectors meet specific performance benchmarks, considering factors like pressure, impulse, vibration, and temperature.

By adhering to these requirements, manufacturers and users can be confident about the reliability and durability of hydraulic connectors. Performance testing is a critical aspect of SAE J1926-3, providing insights into how the connectors will function under real-world conditions. This involves subjecting the connectors to various tests that simulate the hydraulic system’s demands. The standard sets clear guidelines for these tests, ensuring a thorough evaluation of the connectors’ capabilities.

Comparing SAE J1926 Standards with Other Hydraulic Connection Standards

In the realm of hydraulic connections, multiple standards coexist. Comparing SAE J1926 with other relevant hydraulic connection standards sheds light on its uniqueness and advantages. While each standard serves its purpose, SAE J1926 stands out for its meticulous focus on thread specifications, port connection styles, and performance testing. It’s a comprehensive approach that ensures a robust and reliable hydraulic connection system.

Practical Application and Compliance with SAE J1926 Standards

The real test of the effectiveness of any standard lies in its application. Industries and manufacturers apply SAE J1926 standards in real-world hydraulic systems, adhering to the specifications to create connections that are reliable, safe, and efficient. Compliance with these standards is not just about adhering to rules—it’s about ensuring that hydraulic systems function optimally and securely. It’s about prioritizing safety and performance.

Factors to Consider for Optimal Performance

Selecting the appropriate hydraulic connection involves a meticulous evaluation of factors such as pressure ratings, material compatibility, and environmental conditions. Engineers must consider the specific requirements of their applications to choose connections that can withstand varying pressures, resist corrosion, and operate efficiently in diverse settings. By aligning the connection with the system’s demands, optimal performance and longevity are assured.

Preserving the Integrity of Hydraulic Connections

Regular maintenance is paramount to preserving the integrity of hydraulic connections. Inspections should encompass checking for signs of wear, corrosion, or damage to O-ring seals. Additionally, ensuring proper torque during installation and avoiding over-tightening are crucial practices. Adhering to these guidelines safeguards against leaks and ensures the longevity of hydraulic systems.

Conclusion

Hydraulic connections, regulated by standards like SAE J1926, form the lifeline of hydraulic systems, enabling the seamless flow of power and ensuring the efficiency of industrial operations. Understanding the intricacies of these connections and adhering to established standards is fundamental to achieving optimal performance, safety, and reliability in hydraulic machinery.

Post time: Nov-08-2023