In the intricate world of hydraulic systems, adherence to standardized protocols is paramount. SAE J1231, a crucial standard in this domain, defines specific guidelines and requirements for the design and performance of hydraulic fittings.

This article delves deep into SAE J1231, unraveling its complexities and elucidating the question: What is SAE J1231?

What is SAE J1231?

SAE J1231, established by the Society of Automotive Engineers (SAE), defines standards for hydraulic tube fittings used in fluid power systems. These standards ensure consistency and quality in hydraulic connections, contributing to system reliability and safety.

Why are these standards important?

Standardization is crucial in industries like fluid power, ensuring that components work together seamlessly. SAE J1231 sets the benchmarks for hydraulic fittings, promoting uniformity and efficiency in fluid power systems.

Design and Specifications

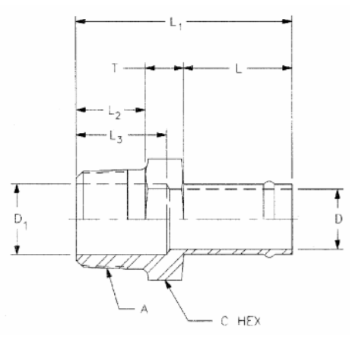

The design specified by SAE J1231 is characterized by its precision. The fittings adhere to specific angles and dimensions, guaranteeing a secure fit and minimizing the risk of leakage. This meticulous approach to design ensures compatibility across different hydraulic systems, enhancing efficiency and safety in operations.

Male Pipe Thread Hose Connector

Dimension of Male Pipe Thread Hose Connector

90-Deg Male Pipe Hose Fitting

45-Deg Male Pipe Hose Fitting

Dimension of 90-Deg and 45-Deg Male Pipe Hose Fitting

90-Deg Straight Thread Hose Fitting

45-Deg Straight Thread Hose Fitting

Dimension of 90-Deg and 45-Deg Straight Thread Hose Fitting

Material Selection

Another critical aspect of SAE J1231 is the selection of materials. The standard mandates the use of materials that withstand hydraulic pressures, resist corrosion, and endure varying temperatures. Common materials include stainless steel, brass, and steel alloys, each chosen for its durability and resilience, ensuring the longevity of the fittings in diverse operating conditions.

Benefits of SAE J1231 Standards

Enhanced Safety

Adhering to standardized fittings mitigates risks associated with incompatible or poorly designed components. This enhances the overall safety and reliability of hydraulic systems.

Interchangeability and Compatibility

Standardization ensures that fittings from different manufacturers are interchangeable and compatible. This interchangeability provides flexibility and convenience during system assembly or maintenance.

Compliance and Certification

Meeting the Standards

Manufacturers need to design and produce hydraulic fittings according to SAE J1231 specifications to achieve compliance. This involves precise engineering and manufacturing processes.

Certification Process

Certification involves rigorous testing and validation to ensure fittings meet the stipulated standards. Compliance with SAE J1231 is a mark of quality and reliability.

The Role of SAE J1231 in Evolving Industries

As industries evolve, SAE J1231 will continue to be a cornerstone, providing a stable framework for hydraulic fittings amidst technological advancements and changing needs.

In conclusion, SAE J1231 standards are fundamental in the world of hydraulic systems, providing a roadmap for the design, manufacturing, and application of hydraulic fittings. Adhering to these standards ensures that hydraulic systems operate efficiently, reliably, and safely across various industries.

Post time: Nov-08-2023