Hydraulic systems play a crucial role in various industries, providing power and control to machinery and equipment. To ensure the efficiency and reliability of these systems, the use of appropriate fittings is essential. O-ring hydraulic fittings have emerged as a popular choice due to their leak-proof design and ease of installation.

In this article, we will explore the world of O-ring hydraulic fittings, their types, advantages, materials, installation tips, troubleshooting, maintenance, and more.

What is an O-Ring Hydraulic Fitting?

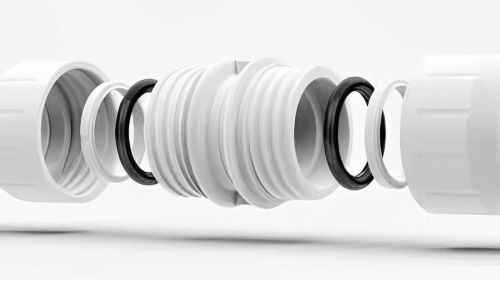

An O-ring hydraulic fitting is a type of connection that utilizes a rubber O-ring to create a secure seal between two components. These fittings are commonly used in hydraulic systems to prevent fluid leakage and maintain system integrity. The O-ring is placed in a groove within the fitting, which compresses when the components are joined, effectively sealing any potential leak paths.

Types of O-Ring Hydraulic Fittings

Flange Fittings

Flange fittings are widely used in high-pressure hydraulic applications. They consist of two flanged components bolted together, with an O-ring sandwiched between them to form a tight seal. Flange fittings offer excellent stability and are suitable for applications that require frequent disassembly.

Straight Thread Fittings

Straight thread fittings are designed for low to medium pressure applications. They feature a male and female component with straight threads and an O-ring to create a reliable connection. These fittings are easy to assemble and disassemble, making them popular in industries where maintenance is routine.

Pipe Fittings

Pipe fittings are used to connect pipes in hydraulic systems. They come in various shapes and sizes, all utilizing O-rings to ensure leak-free connections. Pipe fittings are versatile and are employed in a wide range of hydraulic applications.

Advantages of O-Ring Hydraulic Fittings

Leak-Proof Design

One of the primary advantages of O-ring hydraulic fittings is their leak-proof design. The rubber O-ring creates a reliable seal that prevents fluid leakage even under high pressures, ensuring the system operates efficiently without loss of hydraulic fluid.

Easy Installation and Maintenance

O-ring hydraulic fittings are relatively easy to install and disassemble, simplifying maintenance tasks. The O-ring can be easily replaced when required, allowing for quick and cost-effective repairs.

Wide Temperature Range

O-ring hydraulic fittings can withstand a broad temperature range, making them suitable for applications in extreme environments. They remain flexible and maintain their sealing properties even in hot or cold conditions.

Cost-Effectiveness

Considering their long service life and ease of maintenance, O-ring hydraulic fittings prove to be cost-effective solutions for hydraulic systems.

Common Materials Used for O-Rings

Nitrile (Buna-N)

Nitrile O-rings are widely used due to their excellent resistance to oil, fuel, and other common hydraulic fluids. They are cost-effective and suitable for most standard hydraulic applications.

Viton (FKM)

Viton O-rings are known for their outstanding resistance to high temperatures, aggressive chemicals, and fluids. They are commonly used in applications that involve extreme conditions.

EPDM (Ethylene Propylene Diene Monomer)

EPDM O-rings are ideal for applications requiring excellent weather and ozone resistance. They are commonly used in outdoor hydraulic systems.

Factors to Consider When Choosing O-Ring Hydraulic Fittings

Application Requirements

Consider the specific needs of your hydraulic system, such as pressure, temperature, and fluid compatibility, when selecting O-ring hydraulic fittings.

Pressure Rating

Ensure that the chosen fittings can handle the maximum operating pressure of your hydraulic system.

Temperature Range

Choose O-ring materials that can withstand the temperature extremes present in your application.

Chemical Compatibility

Verify that the O-ring material is compatible with the hydraulic fluids used in your system to avoid deterioration or swelling.

Installation Tips for O-Ring Hydraulic Fittings

Proper Lubrication

Always use an appropriate lubricant to ease the installation of O-ring hydraulic fittings and ensure a proper seal.

Correct O-Ring Size Selection

Choose O-rings of the correct size and cross-sectional diameter to ensure a tight fit and optimal performance.

Tightening Procedures

Follow the manufacturer’s recommended torque specifications when tightening O-ring hydraulic fittings to avoid damage and ensure a secure connection.

Troubleshooting Common Issues with O-Ring Hydraulic Fittings

Leaks

If you encounter leaks, check the O-ring for damage or improper installation. Replace the O-ring if necessary.

O-Ring Damage

Inspect O-rings regularly for signs of wear, cracking, or deterioration. Replace damaged O-rings promptly to prevent leaks.

Incorrect Assembly

Ensure that the components are properly aligned and tightened to prevent misalignment issues that can lead to leaks.

Maintenance and Inspection of O-Ring Hydraulic Fittings

Regularly inspect O-ring hydraulic fittings for signs of wear, damage, or leaks. Perform routine maintenance to ensure the longevity of your hydraulic system.

Frequently Asked Questions (FAQs)

What is the purpose of an O-ring in a hydraulic fitting?

The O-ring in a hydraulic fitting serves to create a reliable and leak-proof seal between two components, preventing fluid leakage.

Can I reuse O-rings in hydraulic fittings?

It is generally not recommended to reuse O-rings, as they may lose their sealing properties over time. It is best to use new O-rings during reassembly.

How long do O-ring hydraulic fittings last?

The lifespan of O-ring hydraulic fittings depends on factors such as application conditions, O-ring material, and maintenance. With proper care, they can last for a long time.

Can I use any type of O-ring in hydraulic fittings?

No, it is crucial to use O-rings made from materials compatible with the hydraulic fluids and environmental conditions of the application.

Are O-ring hydraulic fittings suitable for high-pressure applications?

Yes, O-ring hydraulic fittings, especially flange fittings, are designed to handle high-pressure applications effectively.

Conclusion

O-ring hydraulic fittings play a vital role in ensuring reliable and leak-free connections in hydraulic systems. Their leak-proof design, ease of installation, wide temperature range, and cost-effectiveness make them popular choices in various industries. By considering the application requirements, pressure rating, temperature range, and chemical compatibility, you can select the most suitable O-ring hydraulic fittings for your hydraulic system.

Regular maintenance and inspection will further prolong their lifespan and keep your hydraulic system running smoothly.

Post time: Jul-28-2023