O-ring boss fittings are unsung heroes in the world of fluid handling systems. These simple parts are vital. They ensure countless applications run leak-free and efficiently. From hydraulic systems to plumbing, their importance cannot be overstated.

This guide will explore O-ring boss fittings. It will cover their parts, function, and how to choose them. This info will help both seasoned engineers and DIY fans. You will work confidently with these essential fittings.

Let’s begin by understanding the fundamental components of an O-ring boss fitting.

What is an O Ring Boss Fitting?

An O-ring boss fitting is a specialized pipe or tube fitting equipped with a circular groove designed to accommodate an O-ring. This component plays a crucial role in creating a secure and leak-proof seal between two connected pipes or components. Its versatility and effectiveness have made it indispensable across various industries.

O-ring boss fittings are used in many fields. They are in plumbing, hydraulics, automotive parts, and industrial machines. It is vital that they withstand pressure and prevent leaks. This ensures the systems work well and last a long time.

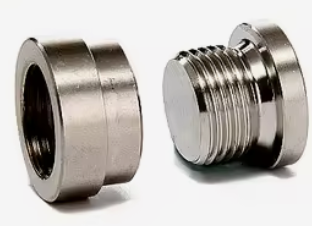

Anatomy of an O Ring Boss Fitting

A typical O-ring boss fitting consists of several key components:

➡️ Boss: This is the protruding cylindrical portion of the fitting that houses the O-ring groove.

➡️ Threads: The external threads on the fitting allow for secure connection to other components, such as pipes or valves.

➡️ Groove: This circular channel machined into the boss accommodates the O-ring, creating the sealing surface.

O-ring boss fittings come in a variety of shapes, sizes, and materials to suit diverse applications. Factors like pipe diameter, fluid type, pressure rating, and environment affect the choice of fitting.

How O Ring Boss Fittings Work

The sealing mechanism of an O-ring boss fitting relies on the elastic properties of the O-ring. When compressed between the boss and the mating surface, the O-ring creates a tight seal that prevents fluid leakage.

Several factors can impact the sealing performance of an O-ring boss fitting, including:

➡️ Pressure: The system pressure determines the required compression of the O-ring.

➡️ Temperature: Extreme temperatures can affect the O-ring’s elasticity and sealing capacity.

➡️ Fluid compatibility: The O-ring material must be compatible with the fluid being handled to prevent swelling or degradation.

➡️ Installation: Proper installation, including correct O-ring orientation and lubrication, is essential for optimal sealing.

Advantages of Using O Ring Boss Fittings

O-ring boss fittings offer several advantages over other sealing methods:

➡️ Cost-effective: They are generally more economical compared to other sealing options.

➡️ Reliable: When properly installed and maintained, O-ring boss fittings provide dependable sealing performance.

➡️ Easy to install: Assembly is relatively straightforward, often requiring minimal tools.

➡️ Versatile: They can be used in a wide range of applications and with various fluids.

Selecting the Right O Ring Boss Fitting

Choosing the appropriate O-ring boss fitting involves considering several factors:

➡️ Fluid type: The compatibility of the O-ring material with the fluid is crucial.

➡️ Pressure: The fitting must be rated for the maximum operating pressure.

➡️ Temperature: The O-ring material should be suitable for the expected temperature range.

➡️ Pipe size: The fitting must match the pipe diameter for a secure connection.

➡️ Material compatibility: The fitting material should be compatible with the fluid and environmental conditions.

A careful evaluation of these factors will help you select the ideal O-ring boss fitting for your specific application.

Check out these other resources ⬇️⬇️⬇️

Master Hydraulic Fitting Identifier with This Easy Guide

NPSM to NPT Adapter: The Ultimate Guide

Installation and Maintenance

Proper installation is essential for the effective performance of O-ring boss fittings. Follow these guidelines:

➡️ Cleanliness: Ensure all components are clean and free of debris.

➡️ Lubrication: Apply a compatible lubricant to the O-ring to facilitate installation and prevent damage.

➡️ Tightening: Tighten the fitting according to the manufacturer’s specifications to achieve a secure seal without over-tightening.

Regular maintenance is crucial for prolonging the life of O-ring boss fittings:

➡️ Inspection: Periodically inspect the fittings for signs of wear, damage, or leakage.

➡️ O-ring care: Replace worn or damaged O-rings promptly.

➡️ Lubrication: Reapply lubricant as needed to maintain O-ring elasticity.

Common Issues and Troubleshooting

Despite their reliability, O-ring boss fittings can encounter problems:

➡️ Leaks: Common causes include damaged O-rings, improper installation, or excessive pressure.

➡️ Damage: Over-tightening or exposure to harsh conditions can damage the fitting.

Troubleshooting involves identifying the root cause of the issue and taking corrective action. This may include replacing the O-ring, retightening the fitting, or using a different fitting material.

Conclusion

O-Ring boss fittings are versatile and reliable components essential in various industries. Knowing their anatomy, function, and selection criteria is vital. It ensures peak performance and prevents leaks. Proper installation and maintenance can maximize the lifespan and effectiveness of these fittings.

If issues persist or you need expert help, consult a pro.

Post time: Aug-12-2024