When it comes to plumbing and industrial piping systems, understanding the right components is crucial. Two terms you might encounter are NPT and NPS, and while they seem similar, they play distinct roles.

This blog post will provide a comprehensive comparison of NPT vs NPS, helping you choose the right option for your project.

What is NPT?

National Pipe Thread (NPT) is a widely used standard in North America for threaded pipe connections. NPT threads boast several key features:

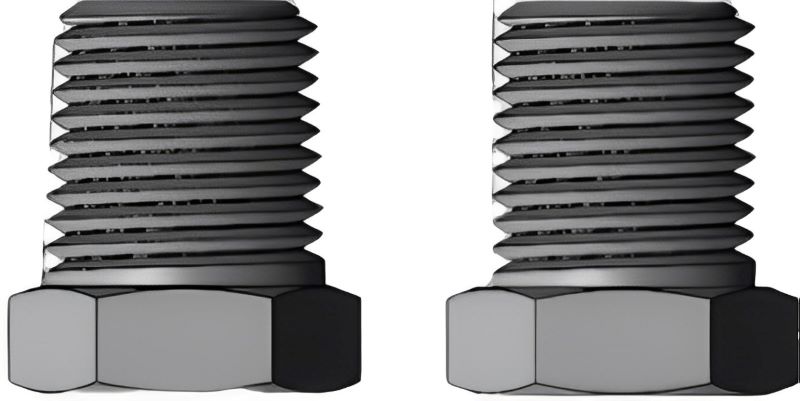

➡️ Tapered Design: This ingenious design allows the threads to form a tighter seal as the connection is made. The seal is better when the fit is tighter.

➡️ 60-Degree Thread Angle: The threads are cut at a specific 60-degree angle, optimizing both sealing and strength.

➡️ Flattened Peaks and Valleys: The flat profile of the peaks and valleys contributes to the self-sealing mechanism of NPT threads.

Applications for NPT threads are numerous. You’ll find them on pipes, fittings, valves, and various other components within plumbing and industrial piping systems.

What is NPS?

National Pipe Straight (NPS) refers to a standardized thread for pipes, typically ranging from 1/8 inch to 12 inches in nominal size. Unlike its counterpart, National Pipe Tapered (NPT), NPS threads have a straight profile, meaning the diameter remains constant along the length.

Key Differences Between NPT and NPS

The defining difference between NPT and NPS lies in their thread profile. NPT threads are tapered, meaning the diameter gradually increases as they move towards the end of the fitting. This wedging action creates a tighter seal as the threads compress when screwed together. In contrast, NPS threads are straight, maintaining a constant diameter throughout their length.

Choosing the Right Standard: NPT vs. NPS

Selecting the right standard depends on your specific needs:

➡️ NPT (National Pipe Tapered)

1. Widely used in plumbing and various industrial applications involving liquids and gases.

2. Ideal for creating leak-resistant connections at moderate to high pressures.

3. Common in pipes, valves, fittings, gauges, and instruments.

➡️ NPS (National Pipe Straight)

1. Less common than NPT, typically used for low-pressure applications where a strong mechanical connection is needed.

2. Often found in hydraulic systems, instrumentation lines, and process piping.

3. Can be used with NPT fittings in specific scenarios, but proper sealing with gaskets or O-rings is crucial.

Additional Considerations

Here are some additional points to remember:

➡️ Interchangeability: While NPT and NPS share the same thread form and pitch, their sealing mechanisms differ. NPT threads will engage with NPS threads for a few turns, but a proper seal won’t be achieved without a gasket for NPS.

➡️ Assembly: NPT’s self-sealing nature allows for hand-tightening with additional tightening using wrenches for good measure. NPS usually requires wrenches to achieve proper tightness and ensure the gasket is compressed effectively.

Frequently Asked Questions (FAQ)

Let’s dive deeper into common questions regarding National Pipe Tapered (NPT) and National Pipe Straight (NPS) threads, building upon the understanding of their key differences.

Q: What’s the main difference between NPT and NPS threads?

A: The primary distinction lies in the thread profile. NPT threads are tapered, creating a self-sealing effect, while NPS threads are straight and rely on separate gaskets or O-rings for sealing.

Q: Can I use NPT and NPS together?

A: In limited scenarios, yes. NPT threads will engage with NPS threads for a few initial turns. However, a proper seal for NPS requires a gasket or O-ring due to the absence of a taper in NPS. Always prioritize proper sealing with gaskets when using NPS with NPT.

Q: Which thread standard is better?

A: There’s no single “better” option. The choice depends on your application. NPT excels in creating leak-resistant connections for liquids and gases at moderate to high pressures. NPS is suitable for low-pressure applications where a strong mechanical bond is needed.

Q: How do I assemble NPT and NPS threads?

A: NPT’s self-sealing nature allows for hand-tightening with additional wrench tightening for good measure. NPS typically requires wrenches to achieve proper tightness and ensure the gasket is compressed effectively. Thread sealant is generally not used with NPS.

Q: What are some common applications for each thread standard?

A: NPT: Plumbing, industrial applications with liquids and gases, pipes, valves, fittings, gauges, and instruments. NPS: Low-pressure hydraulic systems, instrumentation lines, and process piping.

Q: Where can I find more information about NPT and NPS threads?

A: Several resources offer detailed information on pipe threads. You can consult industry standards like ASME B1.20.1 (Pipe Threads) or refer to online resources from engineering websites or pipe manufacturer websites.

Conclusion

NPT and NPS threads serve distinct purposes in pipe fitting. NPT’s tapered design excels in creating leak-proof connections for various fluids and pressures, while NPS offers a strong mechanical connection for low-pressure applications.

Understanding these differences and their sealing mechanisms is essential for selecting the right thread standard for your project’s specific needs.

For more on pipe threads and sizing standards, see resources from industry associations or pipe fitting makers.

Post time: Jun-12-2024