In the realm of hydraulic systems, precision and compatibility are paramount, and metric hydraulic fittings play a crucial role in ensuring seamless fluid connections. Understanding these fittings is vital for anyone working with hydraulic machinery and systems.

This tutorial will provide you with the knowledge you need to solve any hydraulic fitting identification difficulty, whether with technical experience or just starting out.

Exploring Metric Hydraulic Fittings

Metric hydraulic fittings are used extensively in a variety of industries, including manufacturing, construction, and automotive. These fittings are used to connect and seal hydraulic components in order to ensure the smooth flow of fluids under high pressure. In many regions of the world, hydraulic fittings are measured in millimeters using the metric system.

Types of Metric Hydraulic Fittings

Metric hydraulic fittings come in a variety of types, each fulfilling a distinct purpose in hydraulic systems. Let's look at some of the most prevalent types:

1. O-Ring Face Seal (ORFS) Fittings in Metric

Metric ORFS fittings are well-known for their superior sealing qualities. They have an O-ring on the fitting's face that creates a tight seal when attached to the matching ORFS port. These fittings are appropriate for applications requiring strong pressure and vibration resistance.

2. Flareless Metric Bite Type Fittings

Metric flareless bite type fittings, also known as compression fittings, are commonly used in applications that need fast and secure couplings. Without the use of extra sealing components, the bite-type design assures a reliable seal.

3. Flared Metric Fittings

Metric flared fittings are often utilized in high-pressure fluid transfer applications. The flared end of the fitting attaches to a flared tube, resulting in a leak-resistant junction that can tolerate significant pressure.

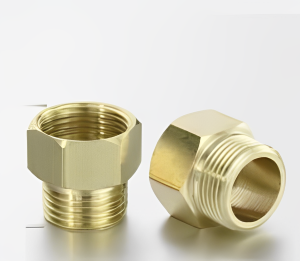

4. Threaded Metric Fittings

Metric threaded fittings are adaptable and frequently used in a wide range of hydraulic systems. They are available in a variety of styles, including straight connectors, elbows, tees, and more. Internal threads on these fittings allow them to be screwed onto external threads on other hydraulic components.

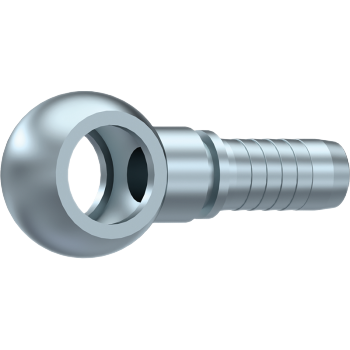

5. Banjo Fittings in Metric

Metric banjo fittings are a one-of-a-kind design that is especially handy when space is limited. They are made up of a hollow bolt with a hole in its side and a fitting that fits through the bolt's hole. Banjo fittings are quite popular in automotive and motorbike applications.

Metric Hydraulic Fittings Identification

The correct identification of metric hydraulic fittings is critical for selecting the correct components for a hydraulic system. Here are the methods to correctly identifying these fittings:

1. Measuring

Measuring the size of metric hydraulic fittings is the first step in recognizing them. Determine the fitting's outer diameter, thread pitch, and length with a caliper or measuring tape. For precise measurements, metric units (millimeters) must be used.

2. Visual Examination

After you've taken your measurements, look over the fitting for any distinguishing features. Look for distinguishing features, markings, or patterns that can help with identification. Important information is frequently imprinted on fittings by manufacturers for easier identification.

3. Use charts to cross-reference

Cross-reference the data with metric hydraulic fitting identification charts once you've collected measurements and visual observations. These charts contain detailed information on various fittings, such as type, thread size, and other details.

4. Seek Professional Help

If you're having trouble recognizing a specific metric hydraulic fitting, don't be afraid to seek help from hydraulic experts or vendors. They have a wealth of expertise and experience, making them great resources for precise identification.

Why do we need to identify metric hydraulic fittings correctly?

For numerous reasons, proper identification of metric hydraulic fittings is critical:

1. Performance and safety

Using the incorrect hydraulic fitting can jeopardize the overall safety and functionality of the hydraulic system. A fitting that does not meet the requirements of the system may cause leaks, pressure drops, or even system failure.

2. Productivity and efficiency

By using the proper metric hydraulic fittings, you can ensure that your hydraulic equipment operates at peak efficiency and production. Fittings that are properly matched allow for smooth fluid flow, reducing energy losses and improving overall performance.

3. Cost-cutting measures

Identifying the correct fitting from the start saves you money by avoiding the need to replace incorrectly chosen components. It also decreases downtime because the system runs smoothly and without interruptions.

Conclusion

Finally, metric hydraulic fitting identification is a necessary ability for anyone who works with hydraulic systems. Understanding fitting types and the identification procedure enables professionals to make informed judgments when purchasing components. Fittings that are properly recognized not only improve system performance but also contribute to its safety and lifespan.

Post time: Aug-07-2023