Metric compression fittings are a fantastic choice for connecting pipes and tubes in plumbing, hydraulic systems, and various other applications. They offer a secure and leak-proof solution with a relatively simple installation process.

This guide will equip you with the knowledge to choose the right metric compression fittings and ensure a successful installation.

Understanding Metric Compression Fittings

Before diving in, let’s understand some key terms:

➡️ Outer Diameter (OD): The external measurement across a pipe, denoted by “OD”

➡️ Inner Diameter (ID): The internal measurement across a pipe, denoted by “ID”

➡️ Thread Pitch: The number of threads per inch (or millimeter for metric)

Metric fittings, unlike imperial fittings, use the metric system for measurements. This means their sizes are denoted in millimeters (mm) instead of inches.

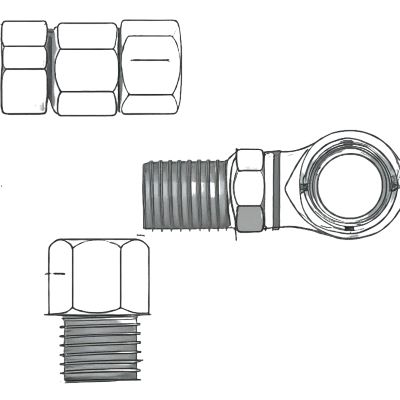

The diagram above showcases a typical metric compression fitting. Here’s a breakdown of its parts:

➡️ Nut: Tightens the compression ring to secure the fitting to the pipe.

➡️ Body: The main housing of the fitting, with threads on one end for connection.

➡️ Compression Ring: A ring that creates a seal between the fitting and the pipe when compressed by the nut.

➡️ Insert: Fits inside the pipe and helps create a tight seal with the compression ring.

Choosing the Right Metric Compression Fitting

Selecting the correct fitting size is crucial. Always base your choice on the outer diameter (OD) of your pipe (refer back to the diagram for reference). Metric compression fittings come in various sizes, so ensure you have a good match for a secure connection.

The material of your fitting also matters. Here’s a quick rundown:

➡️ Brass: The most common choice, offering durability and resistance to corrosion. Great for general plumbing applications.

➡️ Nickel-plated Brass: Provides an extra layer of protection against corrosion and tarnishing. Ideal for applications where appearance matters, like exposed pipes.

➡️ Stainless Steel: Offers the highest level of corrosion resistance. Best suited for demanding environments or applications involving harsh chemicals.

Thread types also play a role. Compression ring style fittings are the most common type for metric compression fittings. Ensure compatibility between the thread type of your fitting and the pipe you’re connecting.

Expert Installation Tips

Safety First! Before starting, always turn off the water supply and use appropriate tools.

Here’s a step-by-step guide for installing a metric compression fitting:

1. Prepare the Pipe: Cut the pipe to the desired length using a pipe cutter. Deburr the cut end (remove sharp edges) with a file to ensure a smooth surface.

2. Insert the Insert and Tighten the Nut: Slide the insert into the pipe, followed by the compression ring. Screw the nut onto the body of the fitting hand-tight.

3. Ensuring a Leak-Proof Connection: Use an adjustable wrench to tighten the nut further, but do not over-tighten. A snug fit is sufficient. Leak detection tape can be applied on the threads for added security (check your local regulations on its use).

Pro Tips:

➡️ Apply a lubricant like Teflon tape (where permitted) to the threads for easier tightening and to prevent seizing.

➡️ Double-check all connections before turning the water supply back on.

Troubleshooting Common Issues

Even with proper installation, occasional issues can arise. Here’s how to tackle common problems:

➡️ Leaks: If you experience leaks, first check if the nut is tightened properly. Re-tighten if necessary, but be cautious of over-tightening. Damaged components like the insert or compression ring might require replacement.

➡️ Loose Connections: Similar to leaks, a loose connection can be remedied by tightening the nut. If the threads are stripped or damaged, you’ll need to replace the fitting.

Conclusion

Using the right metric compression fittings and following proper installation techniques are essential for a successful and leak-free plumbing system. Metric compression fittings offer a convenient and reliable solution with numerous benefits, including ease of installation and secure connections.

Post time: Jul-05-2024