Welcome to the definitive guide on JIS flanges. In this detailed exploration, we will delve into the core of JIS flanges. We will unravel their significance and applications. This guide promises to demystify the world of JIS flanges. Whether you are a seasoned professional or a curious enthusiast, it’s for you.

What is a JIS flange?

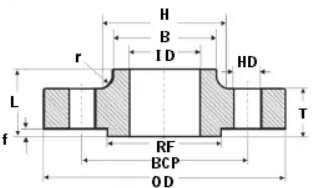

The term JIS stands for Japanese Industrial Standard. A JIS flange is an integral component in piping systems. These flanges make it easy to connect pipes, valves, and equipment. They ensure a secure, leak-proof joint. Understanding their functionality is paramount for anyone dealing with fluid control systems.

The evolution of JIS standards traces back to the industrial growth in Japan. Over the years, these standards have become synonymous with quality and precision.

Types of JIS Flanges: Weld Neck, Slip-On, Blind

➡️ Weld Neck Flanges

Weld Neck Flanges feature a long neck, providing additional support and strength. They are preferred in high-pressure applications due to their structural integrity.

➡️ Slip-On Flanges

Known for ease of installation, Slip-On Flanges slide over the pipe and are welded in place. Their simplicity makes them a popular choice in various industries.

➡️ Blind Flanges

Blind Flanges serve the purpose of closing off the end of a pipe. This design prevents the flow of fluids. It is crucial in certain industrial applications.

Key Features of JIS Flanges: Robust Design, Material Considerations

➡️ Robust Design

JIS flanges are engineered for robustness, ensuring a durable and long-lasting connection. The design prioritizes strength and stability. They are crucial for the reliable operation of piping systems.

➡️ Material Considerations

JIS flanges are made of diverse materials, such as stainless steel and carbon steel. Each material brings its unique properties, catering to specific industry requirements.

Applications Across Industries: Petrochemical, Manufacturing, Marine

➡️ Petrochemical Industry

JIS flanges are extensively used in the petrochemical industry. Their reliability and leak-proof design are vital for handling various chemicals and substances.

➡️ Manufacturing Sector

In manufacturing, JIS flanges help machinery function smoothly. They connect pipes and valves with precision.

➡️ Marine Applications

The marine industry benefits from JIS flanges. They are durable and withstand harsh marine conditions.

Advantages of Choosing JIS Flanges: Reliability, Standardization

➡️ Reliability

JIS flanges are known for reliability. They provide a secure connection that minimizes the risk of leaks. This reliability is crucial in industries where system failure is not an option.

➡️ Standardization

The adherence to JIS standards ensures a standardized approach to piping systems. This promotes compatibility and ease of integration across diverse applications.

JIS Flange Installation Guide: Step-by-Step Instructions

Installing JIS flanges requires precision. Follow this step-by-step guide for seamless installation. Ensure a leak-free and secure connection in your piping system.

Step 1: Gather Necessary Tools and Materials

Get the necessary supplies and tools before beginning the installation process. This typically includes JIS flanges, gaskets, bolts, and nuts. Also, a torque wrench and any other specified components for your application.

Step 2: Verify Flange and Gasket Compatibility

Make sure the chosen JIS flanges and gaskets are compatible. Check their size, material, and pressure ratings. Using mismatched components can compromise the integrity of the connection.

Step 3: Inspect Flange Surfaces

Thoroughly inspect the flange surfaces. Ensure they are clean, smooth, and free of any debris, rust, or imperfections. Use an appropriate cleaning method to achieve a flat and even surface.

Step 4: Place the Gasket

Carefully place the gasket on one of the flange faces. Ensure proper alignment of bolt holes. Confirm that the gasket matches the flange size and material specifications.

Step 5: Align Flange Faces

Align the flange faces, taking care to center them accurately. Proper alignment is crucial for a uniform distribution of pressure. It also prevents leaks.

Step 6: Insert Bolts and Nuts

Insert the bolts through the aligned bolt holes. Ensure they pass through the gasket. Place nuts on the opposite side and hand-tighten them evenly.

Step 7: Torque Bolts to Specifications

Using a torque wrench, tighten the bolts in a crisscross pattern gradually. For information on the proper torque values, consult the manufacturer’s specifications. This ensures uniform compression of the gasket and prevents over-tightening.

Step 8: Conduct a Visual Inspection

After torquing the bolts, visually inspect the flange connection. Look for any signs of misalignment, gaps, or uneven compression. Address any issues promptly to prevent potential leaks.

Step 9: Conduct a Leak Test (Optional)

For critical applications, consider conducting a leak test. This will verify the integrity of the flange connection. This may involve pressurizing the system and inspecting for any signs of leakage.

Step 10: Document Installation Details

Record important details of the installation. This includes torque values, gasket specifications, and any observations made during the process. Future maintenance and troubleshooting may benefit from this documentation.

Maintenance and Care Tips: Ensuring Longevity

Maintaining JIS flanges is essential for their longevity. Explore practical tips to ensure these components continue to perform optimally. Minimize downtime and repair costs.

➡️ Regular Inspection Schedule:

-

Provide a schedule for regular equipment inspections.

-

Check for signs of wear, loose components, or any abnormalities.

-

Prioritize inspections based on the equipment’s usage frequency and criticality.

➡️ Lubrication and Fluid Checks:

-

Follow manufacturer recommendations for lubrication intervals.

-

Ensure proper lubrication of moving parts to reduce friction and wear.

-

Regularly check fluid levels and quality, topping up or replacing as needed.

➡️ Cleaning and Debris Removal:

-

Keep equipment clean from dust, dirt, and debris.

-

Use appropriate cleaning methods to prevent damage to sensitive components.

-

Pay special attention to cooling systems to maintain optimal performance.

➡️ Tighten and Align:

-

Periodically check and tighten loose bolts, nuts, and fasteners.

-

Verify proper alignment of components to prevent unnecessary strain on the equipment.

➡️ Calibration and Adjustment:

-

Calibrate instruments and sensors according to the manufacturer’s specifications.

-

Adjust settings as needed to maintain precision and accuracy.

➡️ Replace Worn Components:

-

Keep an inventory of spare parts, especially for components with a limited lifespan.

-

Replace worn-out parts before they compromise the performance of the equipment.

➡️ Environmental Considerations:

-

Protect equipment from extreme weather conditions when possible.

-

Implement preventive measures for equipment exposed to corrosive or abrasive environments.

➡️ Documentation and Record-Keeping:

-

Maintain detailed records of maintenance activities.

-

Document repairs, replacements, and any notable observations.

-

Use this information for trend analysis and to inform future maintenance strategies.

Common FAQs about JIS Flanges

What does JIS stand for?

➡️ JIS stands for Japanese Industrial Standard. It is a set of standards developed by the Japanese industry. It ensures quality and consistency in various products and systems.

Are JIS flanges interchangeable?

➡️ Yes, JIS flanges are designed to be interchangeable. They ensure compatibility across systems that adhere to the same JIS standards.

How to choose the right JIS flange material?

➡️ Selecting the right material depends on factors such as the type of fluid. It also depends on the temperature and pressure conditions. Consulting with experts can help in making an informed decision.

Can JIS flanges handle high-pressure applications?

➡️ Certainly, JIS flanges, especially weld neck flanges, are designed to handle high-pressure conditions. This design makes them suitable for a wide range of industrial applications.

Are JIS flanges resistant to corrosion?

➡️ JIS flanges are made from materials like stainless steel. They resist corrosion, ensuring durability and longevity in corrosive environments.

Can JIS flanges be used in marine environments?

➡️ Yes, JIS flanges have a robust design and use corrosion-resistant materials. This makes them suitable for marine applications. They can withstand the challenges of saltwater exposure.

Also, read:

Decoding JIC To AN Conversion: Exploring Compatibility And Efficiency

Valve Flanges: A Comprehensive Guide To Understanding The Role Of Flanges In Valves

Conclusion: Summing Up the Essentials

Professionals in fluid control systems need to understand what a JIS flange is. They also need to know its diverse applications. JIS flanges are a preferred choice across industries. They are reliable, standardized, and robust. Whether you’re involved in petrochemicals, manufacturing, or marine applications, JIS flanges are versatile. They ensure a seamless connection in your piping systems.

Post time: Jan-05-2024