Navigating the world of hydraulics can be complex, especially when it comes to understanding thread types. One of the most common and crucial standards is the JIC (Joint Industry Council) thread. While essential for ensuring system integrity, JIC thread charts can often be confusing.

This guide aims to demystify JIC thread charts, providing you with the essential tips and knowledge to confidently select the right fittings for your hydraulic system.

What is a JIC Thread?

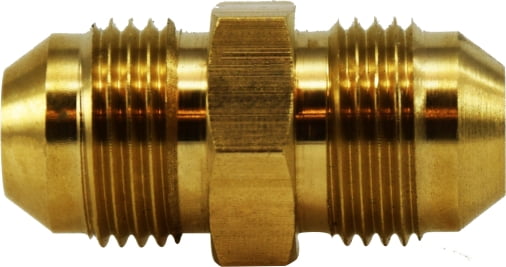

JIC, which stands for Joint Industry Council, is a standard for hydraulic fittings widely used in various industries. A JIC fitting is typically composed of three main parts: the hose, the connector, and the adapter.

JIC threads are different from other types. They have a unique 37-degree flare angle. It creates a secure seal under high pressure. JIC fittings are reliable and versatile. So, they are common in hydraulic systems, automotive parts, and industrial machines.

Breaking Down the JIC Thread Chart

A JIC thread chart is a reference document that provides essential information about JIC fittings. Key elements included in the chart are the fitting size, thread pitch, O-ring size, and pressure rating. Understanding how to read a JIC thread chart is crucial for selecting the correct fitting for your application.

To read a JIC thread chart, start by identifying the required fitting size. This information is typically indicated by a number followed by a letter (e.g., -4, -6, -8). Next, locate the corresponding thread pitch, which specifies the number of threads per inch.

The O-ring size is essential for creating a proper seal and can be found on the chart as well. Finally, check the pressure rating to ensure the fitting can withstand the operating conditions of your system.

JIC fittings are meant to be interchangeable. But, there are misconceptions about JIC thread charts. For instance, not all JIC fittings use O-rings, and some fittings may have different flare angles. To avoid errors, always refer to the specific thread chart provided by the manufacturer.

When choosing a JIC fitting, consider the fluid type, pressure, temperature, and vibration. By analyzing the JIC thread chart and your requirements, you can choose the right fitting. This will ensure optimal performance and safety.

Practical Tips for Using JIC Thread Charts

To accurately use a JIC thread chart, precise measurements are essential. Ensure that you correctly measure the pipe or hose diameter before selecting a fitting size. Additionally, it’s crucial to identify the correct flare angle, as there are two common types: 37-degree flare and 45-degree flare.

JIC 37-degree Flare

JIC 45-degree Flare

Troubleshooting JIC fitting issues often involves three checks. First, check for proper installation. Next, check the tightening torque. Finally, check the O-ring’s condition. Remember to always follow the manufacturer’s recommendations for installation procedures.

Safety is paramount when working with high-pressure systems. Wear the proper personal protective equipment at all times, such as gloves and safety glasses. Check fittings frequently for wear or damage, and replace them as necessary.

Conclusion

To work with hydraulic systems and other uses of JIC fittings, you must understand JIC thread charts. They are essential. By following the tips in this blog, you can confidently select and install the right fittings. This will ensure your equipment is safe and reliable.

We encourage you to share this information with your colleagues and peers to promote a better understanding of JIC thread charts. For more resources, see the JIC thread charts from reliable manufacturers.

Remember, accuracy and precision are key when working with JIC fittings. Learning about JIC thread charts can prevent costly mistakes. It will also ensure your hydraulic systems work their best.

Post time: Aug-15-2024