In the world of hydraulic systems, the JIC 37 degree hydraulic fitting plays a crucial role in ensuring reliable and leak-free connections. These fittings are widely used in various industries due to their exceptional performance and compatibility with high-pressure applications. In this article, we will explore the features, benefits, applications, installation techniques, and maintenance considerations associated with JIC 37 degree fittings.

Let’s delve deeper into the realm of hydraulic fittings and discover why JIC 37 degree fittings are preferred by industry professionals.

What are JIC Fittings?

Hydraulic fittings are essential components that connect different parts of a hydraulic system, allowing for the transmission of fluid and power. JIC fittings, short for Joint Industry Council fittings, are a popular type of hydraulic fittings known for their 37 degree flare angle. This flare angle ensures a secure and tight connection between the fitting and the tubing, minimizing the risk of leaks and ensuring optimal system performance.

JIC 37 degree fittings are commonly used in hydraulic systems due to their reliability and wide acceptance in the industry.

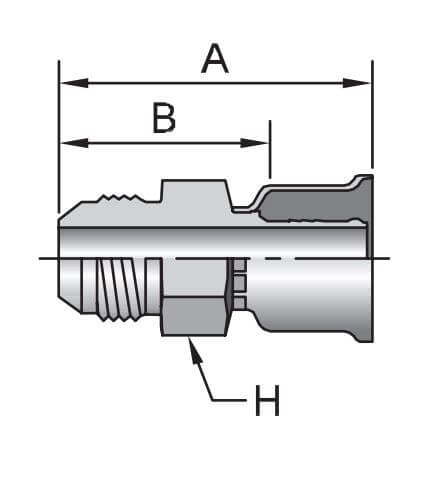

Design and Construction of JIC 37 Degree Fittings

JIC 37 degree fittings are meticulously designed and constructed to withstand high-pressure applications. These fittings are typically made from materials such as stainless steel, brass, or carbon steel, ensuring durability and resistance to corrosion. The fittings feature specific thread specifications and sizes, allowing for compatibility with various hydraulic components.

The flared cone design of JIC 37 degree fittings ensures a solid and reliable connection, eliminating the need for additional sealing materials. Additionally, different types of seals, such as O-rings or metal seals, can be used with JIC fittings to provide a leak-free connection.

Advantages of JIC 37 Degree Fittings

The utilization of JIC 37 degree fittings offers numerous advantages in hydraulic systems. Firstly, these fittings are designed to handle high-pressure applications, providing a secure connection even under extreme conditions. The 37 degree flare angle contributes to the fittings’ superior sealing capabilities, minimizing the risk of leaks and fluid loss. JIC 37 degree fittings are also highly compatible with a wide range of fluids, including hydraulic oils, fuels, and water-based fluids, making them versatile for different applications.

Furthermore, these fittings are relatively easy to install and maintain, saving time and effort during system assembly and maintenance tasks. With their robust construction, JIC 37 degree fittings offer long-lasting performance, reducing the need for frequent replacements.

Common Applications of JIC 37 Degree Fittings

JIC 37 degree fittings find extensive use across various industries and applications. In industrial hydraulic systems, such fittings are employed in machinery, equipment, and pipelines, ensuring smooth fluid transmission and reliable connections. Mobile hydraulic equipment, such as construction machinery and agricultural vehicles, often rely on JIC 37 degree fittings due to their durability and resistance to vibrations.

In the automotive industry, JIC fittings are found in brake systems, power steering systems, and hydraulic clutch systems, delivering efficient and leak-free performance. Additionally, the aerospace and aviation sectors utilize JIC 37 degree fittings in aircraft hydraulic systems, where reliability and safety are of utmost importance.

Proper Installation and Assembly of JIC 37 Degree Fittings

To ensure optimal performance and leak-free connections, proper installation and assembly techniques are crucial when working with JIC 37 degree fittings. The tubing and fittings must be prepared adequately, including cutting the tubing to the correct length and deburring the edges to prevent interference with the sealing surface. Flaring the tubing to the required 37 degree angle is essential for achieving a secure fit with the fitting cone.

Tightening the fittings to the recommended torque specifications is vital to maintain the integrity of the connection without damaging the components. After installation, inspecting for leaks and troubleshooting any issues promptly is necessary to avoid potential problems in the hydraulic system.

Maintenance and Care of JIC 37 Degree Fittings

Regular maintenance and care of JIC 37 degree fittings contribute to their longevity and performance. Inspecting the fittings periodically for wear, damage, or signs of leakage is crucial to identify potential issues early on. Cleaning the fittings and lubricating them with suitable lubricants help prevent corrosion and ensure smooth operation. Proper storage practices, such as protecting the fittings from moisture and contaminants, are important to maintain their quality.

When fittings show signs of wear or damage, they should be replaced promptly to prevent leaks and system failures.

Safety Considerations when Working with JIC 37 Degree Fittings

Working with hydraulic systems, including JIC 37 degree fittings, requires adherence to safety practices. Handling high-pressure systems with caution is essential to prevent injuries and accidents. Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, is crucial to protect against potential hazards.

Understanding fluid compatibility and temperature limitations is vital to ensure the fittings are used within their specified parameters. Following industry standards and guidelines, such as those provided by organizations like the International Organization for Standardization (ISO), helps maintain a safe and reliable hydraulic system.

Choosing the Right JIC 37 Degree Fittings for Your Application

When selecting JIC 37 degree fittings for a specific application, several factors should be considered. Identifying the system requirements, such as operating pressure, temperature, and fluid compatibility, is crucial in choosing the right fittings. Consulting with experts or manufacturers can provide valuable insights and guidance in selecting the appropriate fittings for the intended application.

Environmental factors, such as exposure to extreme temperatures or corrosive environments, should also be taken into account. Evaluating the cost-effectiveness and long-term benefits of different fittings helps make an informed decision and ensures optimal performance and reliability.

Conclusion

JIC 37 degree hydraulic fittings are essential components in hydraulic systems, providing reliable and leak-free connections. Their design, construction, and advantages make them widely accepted in various industries. Proper installation, maintenance, and adherence to safety practices ensure the fittings’ optimal performance and longevity.

By considering system requirements and consulting with experts, selecting the right JIC 37 degree fittings becomes a seamless process. Incorporating these fittings in hydraulic systems enhances their efficiency, reliability, and overall performance, contributing to the smooth operation of machinery and equipment in diverse industries.

Post time: Jun-30-2023