Hydraulic hose fittings are essential components that connect various hydraulic parts, allowing the transmission of fluid power within a hydraulic system. These fittings are essential for keeping hydraulic systems reliable and effective. However, identifying the right type of hydraulic hose fitting can be challenging, considering the diverse range of fittings available in the market. Hydraulic hose fittings adhere to ISO 12151 standard.

In this article, we will delve into the importance of identifying hydraulic hose fittings and provide a step-by-step guide to help you navigate this process effectively.

Importance of Identifying Hydraulic Hose Fittings

The correct identification of hydraulic hose fittings is vital for several reasons. Firstly, using the wrong fitting can lead to leaks, pressure drops, and even system failure. Secondly, the identification process enables you to select the appropriate replacement fitting when required, saving time and resources.

Types of Hydraulic Hose Fittings

DIN Hydraulic Fittings

DIN hydraulic fittings are designed to meet the highest standards of quality and performance in hydraulic systems. This fitting type is based on the installation design standard for 24 ° Metric Fittings, which is specified in ISO 12151-2. This standard ensures the compatible with other fittings in hydraulic systems, allowing for seamless installation and use.

Flange Fittings

Flange fittings are engineered to meet and exceed industry standards for reliability and performance. The installation design standards are specified in ISO 12151-3, which ensure compatibility with other fittings in hydraulic systems. Another incorporated standard is ISO 6162.

ORFS Hydraulic Fittings

ORFS hydraulic fittings are designed to meet and exceed industry standards for reliability and performance. The installation design of these fittings adhere to ISO 12151-1 standard, which ensures compatibility with other fittings in hydraulic systems. ISO 8434-3 standard is also incorporated to further enhance the performance of this type of fitting.

BSP Hydraulic Fittings

The highest industrial standards for quality and dependability, as stated in ISO 12151-6, are met by BSP hydraulic fittings. ISO 8434-6 was also incorporated to improve the performance of BSP hydraulic fittings even more.

SAE Hydraulic Fittings

For various applications, SAE hydraulic fittings provide a dependable and effective solution. They are designed to meet the highest industry requirements, combining the installation design criteria of ISO 12151 with the design standards of ISO 8434.

JIC Hydraulic Fittings

JIC hydraulic fittings are designed to be easily and successfully installed since they adhere to the installation design standard ISO 12151-5. The design standard of ISO 8434-2 is integrated with these fittings to ensure that they fulfill the highest quality and safety criteria.

Step-by-Step Guide for Identifying Hydraulic Hose Fittings

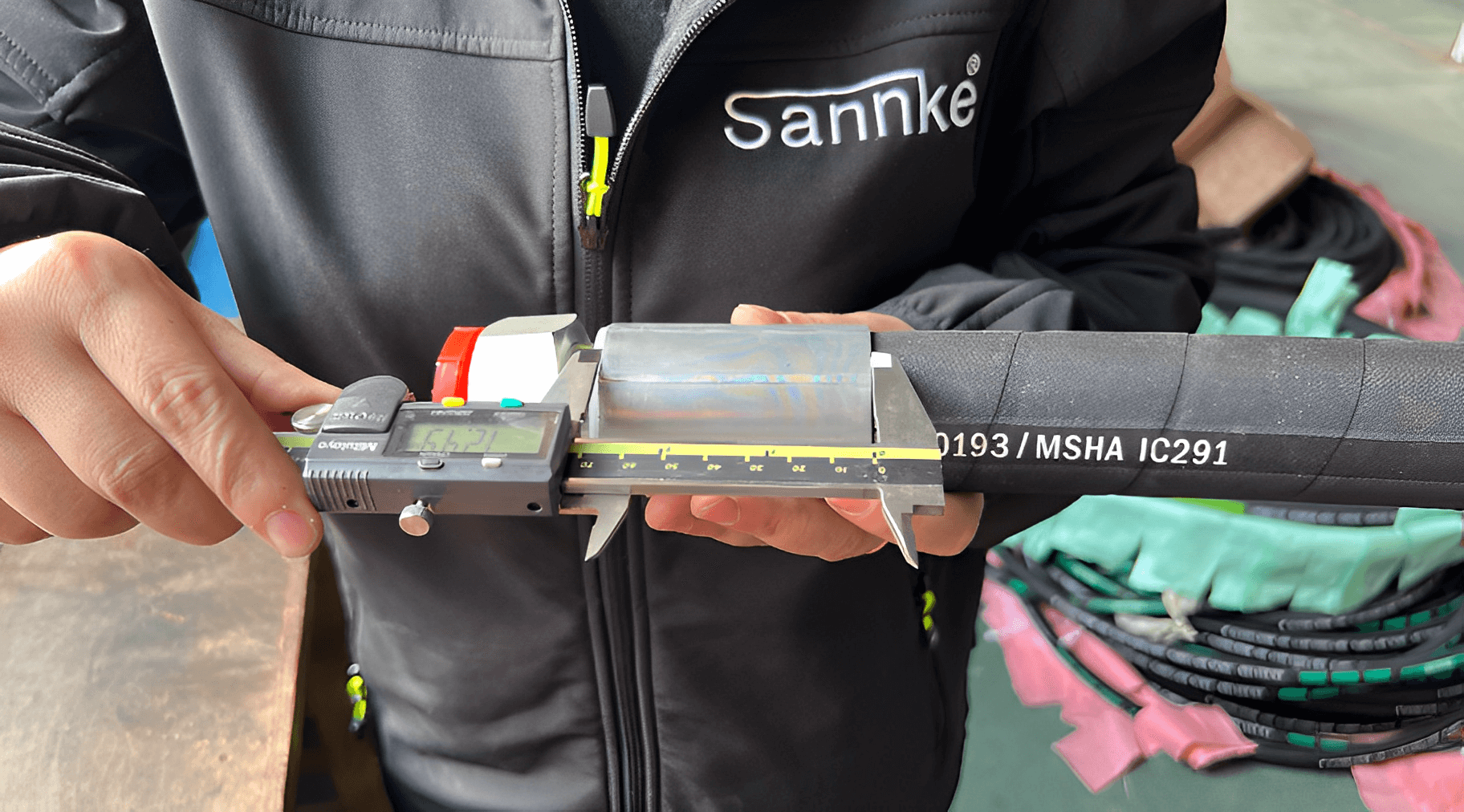

1. Gather Necessary Tools

Before you start the identification process, gather the necessary tools, including a caliper, thread gauge, ruler, and thread pitch gauge.

2. Measure the Thread Size and Pitch

Use the thread gauge and caliper to measure the thread size and pitch accurately.

3. Examine the Flange Shape and Size

Inspect the flange shape and measure its size to determine the correct fitting.

4. Inspect the Quick Disconnect Mechanism

Check the design and size of the quick disconnect fitting for proper identification.

5. Check the Crimp Style and Diameter

Examine the crimp style and measure the diameter to identify the fitting correctly.

6. Evaluate the Compression Type and Fitting

Identify the compression type and fitting specifications for compatibility.

Common Mistakes to Avoid When Identifying Hydraulic Hose Fittings

Ignoring Safety Precautions

Always prioritize safety when working with hydraulic systems. Wear appropriate personal protective equipment and depressurize the system before attempting any identification or replacement.

Not Knowing the Hose Specifications

Understanding the specifications of the hose, such as its material, size, and pressure rating, is essential for identifying the right fitting.

Overlooking Thread Pitch Differences

Thread pitch plays a significant role in fitting compatibility. Overlooking thread pitch differences can lead to leaks and improper connections.

Importance of Properly Identifying Hydraulic Hose Fittings

Ensuring Safety and Reliability

Proper identification of fittings ensures that the hydraulic system operates safely and reliably, minimizing the risk of accidents and equipment damage.

Preventing Costly Downtime

By having the correct fittings on hand and swiftly replacing damaged ones, you can prevent costly downtime and maintain productivity.

Optimizing Hydraulic System Performance

Using the right fittings optimizes the hydraulic system's performance, maximizing efficiency and reducing energy waste.

Tips for Maintaining and Replacing Hydraulic Hose Fittings

Regular Inspections

Regularly inspect hydraulic fittings for signs of wear, corrosion, or damage. Replace worn-out fittings promptly.

Proper Installation Techniques

Ensure that fittings are correctly installed following the manufacturer's guidelines and using the appropriate tools.

Replacing Damaged Fittings

When replacing hydraulic fittings, choose the correct fitting type and size to maintain the system's integrity.

FAQs

Q: Is it necessary to wear protective equipment when identifying hydraulic hose fittings?

A: Yes, wearing protective equipment is crucial to prevent injuries while working with hydraulic systems.

Q: Can I use any fitting if I'm unsure of the exact identification?

A: Using the wrong fitting can lead to system failure and is not recommended. Always make sure to identify the fitting correctly before installation.

Q: How often should I inspect hydraulic fittings?

A: Regular inspections are essential; it is recommended to inspect fittings during routine maintenance checks.

Q: What should I do if I find a damaged hydraulic fitting?

A: If you find a damaged fitting, replace it immediately with the correct type and size to maintain system integrity.

Q: Are crimp fittings reusable?

A: Crimp fittings are not designed to be reusable, and attempting to do so can compromise their performance and safety. Always use new fittings when replacing old ones.

Conclusion

Anyone dealing with hydraulic systems needs to have a basic understanding of how to identify hydraulic hose fittings. It ensures system safety, efficiency, and performance. By following our step-by-step guide and understanding the different types of fittings, you can confidently tackle any hydraulic fitting identification task.

Post time: Aug-07-2023