In the world of hydraulic systems, the proper sealing and protection of components are vital for ensuring optimal performance and longevity. One essential aspect of this protection is the use of hydraulic fitting plugs and caps. These small but crucial accessories play a significant role in safeguarding hydraulic systems from contaminants, preventing leaks, and maintaining system integrity.

In this comprehensive guide, we will explore the importance of hydraulic fitting plugs and caps, their various types and applications, and how they contribute to the overall efficiency and reliability of hydraulic systems.

What are Hydraulic Fitting Plugs and Caps?

Hydraulic fitting plugs and caps are essential components used to seal and protect hydraulic system openings when not in use. They are typically made from high-quality materials, such as steel, brass, or plastic, ensuring durability and resistance to various operating conditions. These fittings are engineered to meet the international standards including, ISO 6149, DIN 7604, ISO 9974-4, SAE_J1926-4, SAE_J531, DIN 908, DIN 910, and DIN 906.

These plugs and caps come in different shapes and sizes to fit the specific requirements of hydraulic fittings, ports, and hoses. By securely sealing the openings, hydraulic fitting plugs and caps prevent the entry of contaminants, such as dust, dirt, moisture, and debris, which can cause damage to sensitive hydraulic components.

Types of Hydraulic Fitting Plugs and Caps

There are several types of hydraulic fitting plugs and caps available, each designed for specific applications and environments. Let's take a look at some commonly used types:

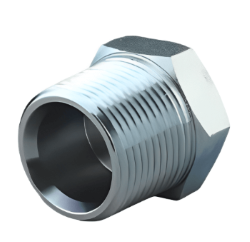

Threaded seal plugs feature internal or external threads that match the corresponding threads on hydraulic fittings or ports. These plugs provide a secure and leak-proof seal, protecting the fittings from contamination and ensuring system integrity. Threaded plugs are available in various thread sizes and materials, allowing for compatibility with a wide range of hydraulic systems.

2. Hydraulic Sealing Plugs Type E

The Type E hydraulic sealing plugs are specifically engineered to fit into threaded ports or openings within hydraulic components such as valves, cylinders, pumps, and manifolds. These plugs are typically made from high-quality materials like stainless steel or brass to ensure durability and resistance to corrosion.

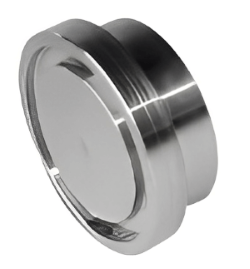

Flanged plugs and caps are equipped with flanges that provide a secure fit and prevent accidental dislodgement. The flange ensures a tight seal, minimizing the risk of leaks and contamination. These plugs and caps are commonly used in applications where high pressure or vibration is present, ensuring reliable protection for hydraulic system openings.

ORFS caps and plugs are specialized components used in hydraulic systems to seal and protect Open-Ended O-Ring Face Seal (ORFS) fittings. ORFS fittings are commonly found in high-pressure hydraulic applications, providing a reliable and leak-free connection between components.

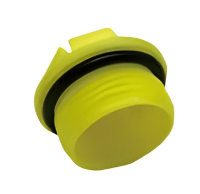

One of the key features of O-Ring Boss plugs is their ability to create a secure and reliable seal. They are equipped with an O-ring that is positioned within the plug body. When the plug is inserted into the O-Ring Boss port and tightened, the O-ring is compressed against the tapered surface of the port, creating a tight seal that prevents fluid from escaping.

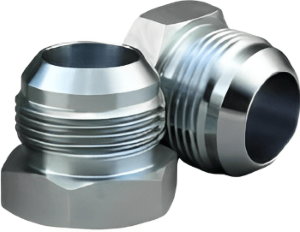

6. JIC Hydraulic Caps And Plugs

One of the key features of JIC hydraulic caps and plugs is their compatibility with JIC fittings. JIC fittings have a 37-degree flare seat and a straight thread, which provides a robust connection between components. JIC caps and plugs are specifically designed to match the dimensions and sealing requirements of these fittings, ensuring a proper and reliable seal when the fitting is not in use.

Magnetic plugs are specialized components used in various systems to capture and remove metallic debris or particles from fluids. They are designed to attract and retain ferrous contaminants, preventing them from circulating within the system and causing potential damage to sensitive components.

A stopping plug, also known as a stopper plug or closure plug, is a versatile component used in various industries and applications to seal or close off openings, ports, or passages. Stopping plugs are designed to provide a secure and reliable seal, preventing the flow of fluids, gasses, or other substances through the opening.

DIN compression plugs are designed to fit into the end of a pipe or tube and provide a tight seal by compressing a ferrule or compression ring against the pipe or tube. They are typically made from materials such as brass, stainless steel, or plastic, ensuring durability and resistance to corrosion.

Bonded seal plugs, also known as Dowty seals or sealing washers, are specialized components used in hydraulic and pneumatic systems to create a reliable and effective seal. They are designed to provide a sealing solution for threaded connections, preventing leakage and maintaining system integrity.

Benefits of Using Hydraulic Fitting Plugs and Caps

Using hydraulic fitting plugs and caps offers several benefits that contribute to the overall performance and longevity of hydraulic systems. Let's explore some of these advantages:

1. Contamination Prevention

Hydraulic systems are highly susceptible to contamination, which can lead to component failure and system downtime. Hydraulic fitting plugs and caps effectively seal system openings, preventing the entry of contaminants such as dirt, dust, and moisture. By maintaining a clean and contaminant-free environment, these plugs and caps help extend the lifespan of hydraulic components and reduce maintenance requirements.

2. Leak Prevention

Leaks in hydraulic systems can result in significant performance issues, loss of hydraulic fluid, and increased operational costs. Hydraulic fitting plugs and caps provide a reliable seal, preventing leaks and ensuring the integrity of the system. By eliminating leaks, these accessories help maintain optimal pressure levels, maximize efficiency, and reduce the risk of damage to surrounding equipment.

3. Easy Identification

Hydraulic fitting plugs and caps often come in different colors or have labeling options, allowing for easy identification of specific system components. This feature simplifies maintenance and troubleshooting tasks, enabling technicians to quickly locate and access the desired hydraulic ports or fittings.

4. Safety Enhancement

Properly sealed hydraulic systems contribute to a safer working environment. By preventing leaks, hydraulic fitting plugs and caps minimize the risk of fluid spray, which can cause slips, falls, and potential injury. Additionally, the use of plugs and caps ensures that no foreign objects or debris enter the system, reducing the chances of accidents caused by system malfunctions.

Selecting the Right Hydraulic Fitting Plugs and Caps

When choosing hydraulic fitting plugs and caps for your specific application, several factors should be considered:

✅ Compatibility

Ensure that the plugs and caps you select are compatible with the hydraulic fittings, ports, and hoses in your system. Consider factors such as thread size, material compatibility, and sealing requirements.

✅ Operating Conditions

Evaluate the operating conditions of your hydraulic system, including pressure, temperature, and environmental factors. Select plugs and caps that can withstand these conditions without compromising performance or integrity.

✅ Quality and Durability

Opt for high-quality plugs and caps that are built to last. Consider materials that offer resistance to corrosion, abrasion, and chemical exposure, depending on the specific requirements of your application.

✅ Ease of Use

Look for plugs and caps that are easy to install and remove, allowing for efficient access to hydraulic system openings when needed. Quick and secure installation helps minimize downtime during maintenance or repairs.

Installation and Maintenance of Hydraulic Fitting Plugs and Caps

Proper installation and maintenance practices are essential for the effective use of hydraulic fitting plugs and caps. Follow these reminders to ensure optimal performance and longevity:

1. Clean the Area

Before installing plugs and caps, clean the surrounding area to remove any dirt, debris, or contaminants. This step helps prevent the introduction of foreign particles into the hydraulic system during installation.

2. Lubrication (If Required)

Depending on the specific plugs and caps being used, lubrication may be necessary to ensure a smooth and secure fit. Follow the manufacturer's recommendations regarding lubrication and apply it as directed.

3. Secure Fit

When installing plugs and caps, ensure a secure fit to prevent dislodgment during operation. Follow the proper installation procedures provided by the manufacturer, such as tightening to the recommended torque.

4. Regular Inspection

Periodically inspect the plugs and caps for signs of wear, damage, or deterioration. Replace any components that show signs of degradation to maintain the integrity of the hydraulic system.

5. Removal and Reinstallation

When removing plugs and caps for maintenance or system access, handle them with care to avoid damage. Clean the plugs and caps before reinstallation and ensure a proper fit to maintain the desired sealing performance.

FAQs About Hydraulic Fitting Plugs and Caps

Q: What are hydraulic fitting plugs and caps used for?

A: Hydraulic fitting plugs and caps are used to seal and protect hydraulic system openings when not in use. They prevent the entry of contaminants and maintain system integrity.

Q: Are hydraulic fitting plugs and caps reusable?

A: Yes, many hydraulic fitting plugs and caps are designed for multiple uses. However, it is essential to inspect them regularly and replace any components showing signs of wear or damage.

Q: Can hydraulic fitting plugs and caps withstand high-pressure applications?

A: Yes, there are hydraulic fitting plugs and caps specifically designed to withstand high-pressure environments. These plugs and caps ensure reliable sealing and protection even under demanding operating conditions.

Q: Do hydraulic fitting plugs and caps come in different sizes?

A: Yes, hydraulic fitting plugs and caps are available in various sizes to match different hydraulic fittings, ports, and hoses. It is crucial to select the correct size to ensure a proper fit and effective sealing.

Q: Can hydraulic fitting plugs and caps be customized?

A: Yes, some manufacturers offer customization options for hydraulic fitting plugs and caps. Customization may include color-coding, labeling, or special materials to meet specific requirements.

Q: Are hydraulic fitting plugs and caps interchangeable between different hydraulic systems?

A: It depends on the compatibility of the plugs and caps with the specific hydraulic systems. It is recommended to consult the manufacturer's guidelines and select plugs and caps suitable for your particular system.

Conclusion

Hydraulic fitting plugs and caps are invaluable accessories for protecting hydraulic systems from contamination and ensuring system integrity. By providing a reliable seal, they prevent leaks, extend component lifespan, and contribute to a safer working environment. When selecting hydraulic fitting plugs and caps, consider factors such as compatibility, operating conditions, and durability.

By following proper installation and maintenance practices, you can maximize the benefits of these essential components. Invest in high-quality hydraulic fitting plugs and caps to safeguard your hydraulic systems and optimize their performance.

Post time: Jul-14-2023