In the intricate world of hydraulic systems, hydraulic fittings stand as the unsung heroes that bridge the gap between various components. They enable the seamless flow of hydraulic fluid, ensuring the efficiency and reliability of machinery across industries.

In this detailed guide, we delve deep into the art of hydraulic fitting identification, unveiling the methods, tools, and knowledge required to decipher the code of these vital connectors.

The Crucial Role of Hydraulic Fittings

Hydraulic fittings play a pivotal role in hydraulic systems, acting as the linchpin that unites diverse components into a cohesive whole. From pumps to hoses, cylinders to valves, these fittings are the critical links that enable fluid to move from one point to another. Their importance is underscored by their ability to control flow, prevent leakage, and ensure optimal performance within the hydraulic ecosystem.

Understanding Hydraulic Fitting Chart

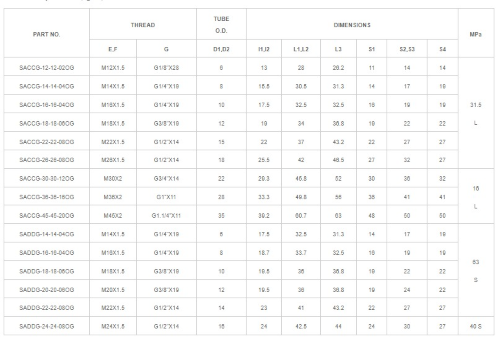

To identify hydraulic fittings accurately, a hydraulic fitting chart becomes an invaluable resource. This chart is a visual representation of different types of fittings, helping users match the physical characteristics of a fitting to its corresponding category. Each fitting type is depicted with its unique shape, dimensions, and connection method, making it easier to navigate the intricate world of hydraulic fittings.

Decoding the Visual Clues

When confronted with a hydraulic fitting, the identification process involves observing its external features and matching them to the details on the hydraulic fitting chart. Here are some key visual clues to consider:

1. Thread Type and Size

The thread type and size are crucial in identifying hydraulic fittings. Threads can be straight or tapered, and measuring the diameter and pitch helps determine the size. The fitting’s connection method, whether through threading or flaring, is also essential.

2. Shape and Design

The fitting’s shape and design, including the number of connection points and any unique features, offer vital clues. These distinctive characteristics guide you towards the fitting’s classification on the hydraulic fitting chart.

3. Material and Finish

Hydraulic fittings come in various materials, including steel, brass, and stainless steel, each with its unique appearance and finish. Examining the material and finish aids in narrowing down the possibilities during identification.

Tools of the Trade

To accurately identify hydraulic fittings, it’s essential to have the right tools at your disposal:

1. Calipers and Gauges

Calipers and gauges allow precise measurements of thread diameter, pitch, and angle, aiding in determining the fitting’s size and thread type.

2. Thread Identification Kits

Thread identification kits comprise sample fittings with various thread types and sizes. These kits serve as a hands-on reference for comparing and identifying the fitting in question.

3. Visual Guides and Charts

Hydraulic fitting charts and visual guides act as your go-to references, providing a visual representation of fitting types, sizes, and configurations.

Expert Knowledge: Tapping into Resources

In the journey of hydraulic fitting identification, expert knowledge is invaluable. Collaborating with seasoned hydraulic engineers, manufacturers, or suppliers can provide insights that extend beyond charts and tools. These experts possess a wealth of experience, allowing them to identify fittings based on nuances that might elude the untrained eye.

Online Resources: Tapping into Technology

The digital age has ushered in a wealth of online resources dedicated to hydraulic fitting identification. Websites, forums, and online communities offer platforms for enthusiasts and professionals to share knowledge, seek advice, and engage in discussions about hydraulic fittings. These platforms often provide detailed images, explanations, and real-life examples, enriching your understanding of hydraulic fitting identification.

The Importance of Accurate Identification

Accurate hydraulic fitting identification is not merely an academic pursuit—it has practical implications. Using the wrong fitting can lead to leaks, reduced efficiency, and even catastrophic system failures. Proper identification ensures that the right fitting is selected for the job, optimizing the system’s performance and longevity.

Wrapping Up

In the ever-evolving landscape of hydraulic systems, the ability to identify hydraulic fittings accurately is a skill that empowers engineers, technicians, and enthusiasts alike. Armed with the knowledge of hydraulic fitting charts, visual clues, and the support of experts and online resources, the daunting task of hydraulic fitting identification transforms into a systematic and rewarding endeavor.

Subsequently, the next time you encounter a hydraulic fitting and wonder, “How do I identify a hydraulic fitting?” remember that a bunch of resources and information are at your fingertips, waiting to be explored.

Post time: Aug-24-2023