Hydraulic systems are the backbone of many industries, powering heavy machinery and intricate processes. However, these systems can pose significant risks if not properly maintained. One crucial safety measure often overlooked is hydraulic hose sheathing. This protective layer plays a vital role in preventing accidents, reducing downtime, and extending the life of your hydraulic equipment.

In this post, we’ll delve into the importance of hydraulic hose sheathing, exploring its benefits, types, and best practices for selection and maintenance.

Understanding Hydraulic Hose Sheathing

What is hydraulic hose sheathing?

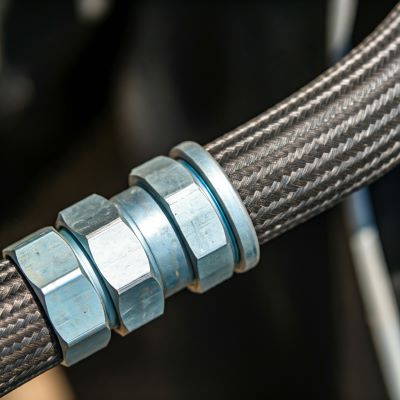

Hydraulic hose sheathing is a protective outer layer that encases the inner hose and fittings of a hydraulic system. This layer is crucial in safeguarding the system from various external factors that can lead to premature failure, leaks, and potential accidents.

Materials commonly used in hydraulic hose sheathing

Several materials are commonly used in hydraulic hose sheathing, each offering specific advantages:

➡️ Rubber: Provides excellent flexibility and resistance to abrasion.

➡️ Thermoplastic elastomer (TPE): Offers good flexibility, resistance to chemicals, and a wide operating temperature range.

➡️ Polyurethane: Known for its high abrasion resistance, durability, and resistance to oil and grease.

➡️ Metal: Provides superior protection against mechanical damage, heat, and fire.

The role of sheathing in hydraulic systems

The primary role of sheathing in hydraulic systems is to protect the inner hose from:

➡️ Mechanical damage: Abrasion, cuts, and punctures

➡️ Environmental factors: UV radiation, ozone, and extreme temperatures

➡️ Chemical exposure: Oil, grease, and other corrosive substances

The Risks of Unprotected Hydraulic Hoses

Common hazards for unprotected hydraulic hoses

Unprotected hydraulic hoses are susceptible to a variety of hazards, including:

➡️ Abrasion: Rubbing against nearby surfaces can wear down the hose’s outer layer.

➡️ Puncture: Sharp objects can easily penetrate the hose, causing leaks.

➡️ Heat damage: Exposure to high temperatures can weaken the hose material.

➡️ Chemical degradation: Contact with chemicals can deteriorate the hose’s structure.

Consequences of hose wear and damage

The consequences of hose wear and damage can be severe:

➡️ Hydraulic fluid leaks: Leaking fluid can contaminate equipment and the environment.

➡️ System downtime: Leaks can lead to system failure and costly repairs.

➡️ Safety hazards: Leaking hydraulic fluid under pressure can cause serious injuries.

The impact of leaks on system performance and safety

Leaks in hydraulic systems can significantly impact performance and safety:

➡️ Reduced system efficiency: Leaks can lower hydraulic pressure and reduce system responsiveness.

➡️ Increased energy consumption: Leaks can waste energy and increase operating costs.

➡️ Safety risks: Leaking hydraulic fluid can create slippery surfaces and fire hazards.

How Hydraulic Hose Sheathing Enhances Safety

Protection against abrasion and external damage

Hydraulic hose sheathing provides a physical barrier that protects the hose from abrasion, cuts, and punctures. This helps to extend the hose’s lifespan and reduce the risk of leaks.

Reducing the risk of hose bursts in high-pressure systems

Sheathing can help to reinforce the hose’s structure, making it more resistant to bursting under high pressure. This is especially important in high-pressure applications.

Shielding hoses from environmental hazards like UV rays and chemicals

Sheathing can protect hoses from harmful UV radiation, which can degrade the hose material over time. Additionally, sheathing can provide resistance to chemicals, preventing them from damaging the hose.

Visit these other resources for a wider knowledge ⬇️⬇️⬇️

Expert Tips on Hydraulic Bulkhead Fittings Selection

JIC Fitting Thread Sizes: Tips for Perfect Connections

Types of Hydraulic Hose Sheathing

Spiral guard sheathing for heavy-duty applications

Spiral guard sheathing is a type of metal sheathing that provides excellent protection against mechanical damage and heat. It is ideal for heavy-duty applications where hoses are exposed to harsh environments.

Textile-based sheathing for flexibility and lightweight protection

Textile-based sheathing is a lightweight and flexible option that offers good protection against abrasion and environmental factors. It is commonly used in applications where weight and flexibility are important.

Fire-resistant sheathing for high-temperature environments

Fire-resistant sheathing is designed to withstand high temperatures and prevent the spread of fire. It is essential for applications in hazardous environments.

Key Benefits of Using Hydraulic Hose Sheathing

➡️ Extended lifespan of hydraulic hoses: Sheathing protects hoses from damage, extending their lifespan.

➡️ Lower maintenance costs and reduced downtime: By preventing leaks and failures, sheathing can help to reduce maintenance costs and downtime.

➡️ Improved workplace safety and compliance with safety standards: Sheathing helps to create a safer working environment by reducing the risk of accidents and injuries.

Selecting the Right Sheathing for Your Needs

Factors to consider: material, size, and application

When selecting hydraulic hose sheathing, consider the following factors:

➡️ Material: Choose a material that is compatible with the fluid and environmental conditions.

➡️ Size: Ensure that the sheathing is the correct size for the hose.

➡️ Application: Select a sheathing type that is suitable for the specific application.

Matching sheathing types with specific industry requirements

Different industries have unique requirements for hydraulic hose sheathing. For example, the construction industry may require sheathing that is resistant to abrasion and puncture, while the automotive industry may need sheathing that is flexible and lightweight.

Tips for proper installation and maintenance

To ensure optimal performance and safety, follow these tips for installing and maintaining hydraulic hose sheathing:

➡️ Proper installation: Install the sheathing according to the manufacturer’s instructions.

➡️ Regular inspection: Inspect the sheathing regularly for signs of wear and damage.

➡️ Prompt replacement: Replace damaged sheathing immediately.

Conclusion

Hydraulic hose sheathing is an essential component of any hydraulic system. By protecting hoses from damage and leaks, sheathing helps to improve system safety, reliability, and efficiency. Investing in high-quality sheathing solutions can save you time, money, and potential hazards.

Post time: Nov-21-2024