In the world of plumbing, fluid systems, and industrial applications, it's essential to be able to identify and differentiate between various types of fittings. Two common thread types that often cause confusion are BSP (British Standard Pipe) and NPT (National Pipe Thread) fittings.

In this comprehensive guide, we'll explore how to identify BSP and NPT fittings, their differences, and where they are commonly used.

Understanding BSP Fittings

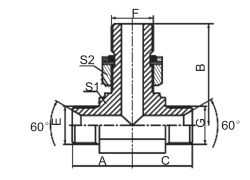

BSP Male 60° Seat / Metric Male Adjustable Stud End L-Series ISO6149-3 Branch Tee

What are BSP Fittings?

BSP, which stands for British Standard Pipe, is a widely used thread standard in Europe and other parts of the world. These threads come in two primary variations: BSPP (British Standard Parallel Pipe) and BSPT (British Standard Taper Pipe).

BSPP Threads: These threads are parallel, meaning they maintain a consistent diameter along the length of the thread. BSPP threads do not taper, making them suitable for sealing with washers or O-Rings.

BSPT Threads: Unlike BSPP, BSPT threads have a taper design. They get progressively larger in diameter toward the end of the thread, which is crucial for creating a tight, leak-free seal.

BSP fittings are commonly found in plumbing systems, water pipes, and gas lines in regions that adhere to British standards. Their reliability and versatility make them suitable for various applications, including fluid and gas handling.

Delving into NPT Fittings

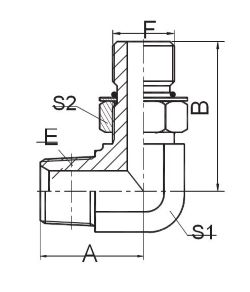

90° NPT Male / SAE O-Ring Boss

What are NPT Fittings?

NPT, or National Pipe Thread, is a thread standard primarily used in the United States and Canada. Unlike BSP threads, NPT threads have a taper design, which means they get larger in diameter as you move along the thread. This tapering is essential for creating a secure and leak-free seal. NPT threads are further categorized into various sizes, with common examples like 1/8", 1/4", 3/8", and so on, each denoting the nominal pipe size (NPS) and the number of threads per inch (TPI).

Where are NPT Fittings Used?

NPT fittings are prevalent in plumbing systems, industrial machinery, and hydraulic applications in North America. Their tapered design allows for a secure fit and leak prevention, making them ideal for handling liquids and gasses.

How to Identify BSP and NPT Fittings

Identifying BSP and NPT fittings is crucial for proper installation and maintenance. Here are some key ways to distinguish between the two:

Thread Angle: Check the thread angle. BSP threads have a 55-degree thread angle, while NPT threads have a 60-degree thread angle. This angle difference is subtle but significant.

Taper vs. Parallel: Examine the thread design. If the threads taper down the fitting, it's likely NPT. If the threads are parallel, it's probably BSP.

Measurement: Measure the diameter of the fitting's threads. BSP threads have a consistent diameter, while NPT threads gradually increase in size along the length of the thread.

Standard Labels: Look for standard labels or markings on the fitting. Manufacturers often imprint the thread type for easy identification.

Visual Comparison: If you have a known fitting of the opposite type, compare it visually with the fitting in question. The differences in thread design should become apparent.

FAQs (Frequently Asked Questions)

Can BSP and NPT fittings be connected directly?

No, BSP and NPT fittings are not designed to be connected directly. Their different thread designs may result in leaks or an insecure fit. Adapters are available to bridge the gap between these two thread types.

Can I use Teflon tape to make BSP and NPT fittings compatible?

Teflon tape can help create a tighter seal on threads, but it may not make BSP and NPT threads fully compatible. Adapters designed for specific thread types are recommended for secure connections.

Is it common to find both BSP and NPT fittings in the same plumbing or hydraulic system?

It is not uncommon to encounter both thread types in systems, particularly in regions with international components. Adapters and careful installation are necessary to ensure compatibility.

Are there any advantages of using one thread type over the other?

The choice between BSP and NPT threads often depends on regional standards and specific applications. Both thread types are reliable when used correctly, with each having its strengths.

Do BSP and NPT fittings have a universal color code for easy identification?

While color coding is not universal, some manufacturers may use color markings to indicate thread types. However, relying solely on color coding may lead to errors, so it's essential to verify thread types visually.

Can BSP and NPT fittings be used interchangeably with metric threads?

BSP and NPT threads are not directly interchangeable with metric threads due to differences in thread design and sizing. Adapters or conversion fittings may be necessary for compatibility.

Conclusion

Distinguishing between BSP and NPT fittings is crucial for successful plumbing and fluid system installations. Understanding their differences in design and where they are commonly used is essential for ensuring a secure and leak-free connection. By following the guidelines outlined in this guide and utilizing adapters when needed, you can confidently identify and work with BSP and NPT fittings in various applications.

Post time: Sep-29-2023