Hydraulic systems are the backbone of many industries, powering heavy machinery and precision equipment. A seemingly small component, the elbow, plays a crucial role in the efficient operation of these systems. Understanding the importance of selecting the right elbow for your hydraulic ram is key to ensuring optimal performance and longevity.

What is an Elbow for a Hydraulic Ram?

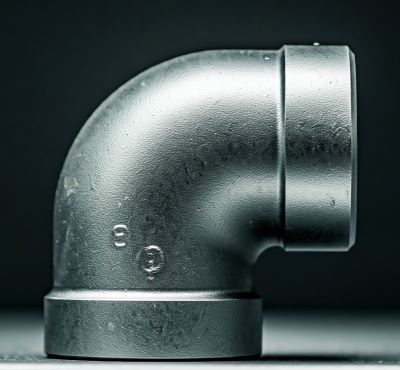

A hydraulic elbow is a fitting that changes the direction of fluid flow within a hydraulic system. These fittings are essential for routing fluid to different components, such as cylinders, valves, and motors. The design and material of an elbow significantly impact the overall performance of a hydraulic system.

Impact of the Right Elbow on Hydraulic Ram Performance

➡️ Improved Fluid Flow and Pressure: A well-designed elbow minimizes flow restrictions, ensuring that fluid can move efficiently through the system. This leads to optimal pressure delivery to hydraulic rams and other components.

➡️ Enhanced System Longevity: The right elbow can significantly extend the lifespan of a hydraulic system. By reducing stress on the system and preventing leaks, elbows contribute to overall system reliability.

Common Issues Caused by Incorrect Elbow Selection

➡️ Restricted Fluid Flow and Pressure Loss: An improperly sized or poorly designed elbow can impede fluid flow, leading to reduced system performance and potential damage to components.

➡️ System Wear, Leaks, and Inefficiencies: Incorrect elbows can cause excessive stress on the system, leading to premature wear, leaks, and reduced efficiency.

Types of Elbows for Hydraulic Rams

➡️ 45-Degree Elbows: These elbows provide a gentle bend in the fluid flow path, minimizing pressure loss and reducing stress on the system.

➡️ 90-Degree Elbows: These elbows create a sharp bend, which can increase pressure loss if not designed correctly.

➡️ 180-Degree Elbows: These elbows allow for a complete reversal of fluid flow direction.

Materials Matter: Choosing the Best Material for Hydraulic Elbows

The material of an elbow is crucial for its durability and resistance to corrosion. Common materials include:

➡️ Steel: A strong and durable material suitable for high-pressure applications.

➡️ Brass: Offers good corrosion resistance and is often used in lower-pressure systems.

➡️ Stainless Steel: Highly resistant to corrosion and ideal for harsh environments.

Installation Best Practices for Hydraulic Elbows

➡️ Proper Installation: Ensure that elbows are installed correctly, with the correct orientation and alignment.

➡️ Torque Specifications: Tighten fittings to the specified torque to prevent leaks and damage.

Maintenance Tips to Prolong the Life of Hydraulic Elbows

➡️ Regular Inspections: Visually inspect elbows for signs of wear, cracks, or corrosion.

➡️ Cleaning and Lubrication: Clean elbows regularly to remove dirt and debris. Apply a suitable lubricant to prevent corrosion and ensure smooth operation.

Conclusion: Ensuring Optimal System Health with the Right Elbow

Selecting and maintaining the right elbow is essential for the optimal performance and longevity of your hydraulic system. By understanding the factors that influence elbow performance, you can make informed decisions to ensure the reliability and efficiency of your equipment.

Post time: Oct-30-2024