Coupling quick release systems are innovative solutions designed to rapidly connect and disconnect fluid or gas lines. These systems offer a significant advantage over traditional threaded or bolted connections, providing a faster, more secure, and efficient way to manage fluid flow.

What Is a Coupling Quick Release?

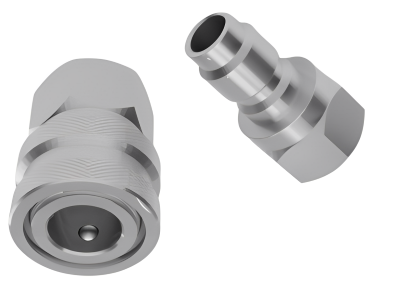

A coupling quick release is a mechanical device that allows for the rapid connection and disconnection of fluid or gas lines. It typically consists of a male and female half, which are connected by a simple latching mechanism. When the two halves are aligned and pushed together, they lock securely, creating a leak-proof seal.

Key components that make up a quick release coupling

A typical quick release coupling consists of:

➡️ Male and female halves: The two main components that connect to the fluid or gas lines.

➡️ Latching mechanism: The mechanism that secures the connection.

➡️ Sealing elements: O-rings or other sealing components that ensure a leak-proof seal.

➡️ Sleeve or collar: A protective covering that shields the coupling mechanism.

The science behind secure yet easily detachable connections

Quick release couplings rely on a combination of mechanical principles to achieve a secure yet easily detachable connection. The latching mechanism engages the male and female halves, creating a tight fit. The sealing elements, such as O-rings, provide a leak-proof seal around the connection.

Types of Coupling Quick Release Systems

Hydraulic quick release couplings and their applications

Hydraulic quick release couplings are designed to handle high-pressure hydraulic fluids. They are commonly used in heavy machinery, construction equipment, and industrial hydraulic systems.

Pneumatic quick release couplings and common uses

Pneumatic quick release couplings are used for connecting and disconnecting pneumatic tools and equipment. They are commonly found in automotive repair shops, manufacturing facilities, and construction sites.

Other types: water, fuel, and multipurpose quick release couplings

Other types of quick release couplings include:

➡️ Water couplings: Used for connecting and disconnecting water hoses.

➡️ Fuel couplings: Used for fueling vehicles and equipment.

➡️ Multipurpose couplings: Designed to handle a variety of fluids and gases.

Choosing the right type based on specific system requirements

When selecting a quick release coupling, consider the following factors:

➡️ Fluid type: The type of fluid or gas to be conveyed.

➡️ Pressure rating: The maximum pressure the coupling can handle.

➡️ Flow rate: The fluid or gas’s necessary flow rate.

➡️ Connection type: The type of connection (e.g., pipe thread, hose barb).

➡️ Environmental conditions: The operating temperature and humidity.

Top Benefits of Using a Coupling Quick Release

➡️ Time-saving: Quick connections and disconnections reduce downtime.

➡️ Safety: Secure connections prevent leaks and accidental releases.

➡️ Reduced wear: Minimized handling reduces wear and tear on equipment.

➡️ Versatility: One coupling system can be used for multiple applications.

How Coupling Quick Release Works in Various Industries

Time is critical in the fast-paced industrial environment of today. Quick release couplings increase productivity, decrease downtime, and simplify operations. They are particularly crucial in industries where frequent connections and disconnections are necessary, such as:

➡️ Manufacturing: For rapid tool changes and equipment setups

➡️ Automotive: In automotive repair and maintenance

➡️ Construction: For fluid and air tool connections

➡️ Agriculture: In irrigation systems and farm machinery

➡️ Medical: For sterile and efficient fluid transfer

How coupling quick release improves efficiency and safety

Quick release couplings offer several key benefits:

➡️ Time-saving: Rapid connections and disconnections minimize downtime.

➡️ Safety: Secure connections prevent leaks and accidental disconnections.

➡️ Reduced wear: Minimized handling reduces wear and tear on equipment.

➡️ Versatility: One coupling system can be used for multiple applications.

Choosing the Right Coupling Quick Release for Your Needs

Key factors to consider: size, material, and pressure ratings

When selecting a quick release coupling, consider the following factors:

➡️ Size: The diameter of the fluid or gas line.

➡️ Material: The material of the coupling, such as brass, steel, or stainless steel.

➡️ Pressure rating: The maximum pressure the coupling can handle.

Material options and their impact on durability and performance

The choice of material for a quick release coupling depends on the specific application and environmental conditions. Common materials include:

➡️ Brass: Durable and corrosion-resistant.

➡️ Steel: Suitable for high-pressure applications, it is robust and long-lasting.

➡️ Stainless steel: Extremely resistant to corrosion, perfect for challenging conditions.

Understanding pressure and temperature ratings for safe usage

Choosing a coupling with a pressure rating higher than the system’s maximum operating pressure is essential. Additionally, the coupling should be able to withstand the temperature range of the fluid or gas.

Special considerations for hazardous environments or delicate systems

For hazardous environments, consider using explosion-proof or chemically resistant couplings. For delicate systems, opt for couplings with precise sealing mechanisms to prevent leaks and contamination.

Installation and Maintenance Tips for Coupling Quick Release Systems

Step-by-step guide for a secure installation

1. Clean the coupling and the connected components.

2. Align the male and female halves of the coupling.

3. Press the two parts together until they firmly lock.

4. Visually inspect the connection for any leaks.

Regular maintenance practices to keep quick release couplings in top shape

➡️ Regularly inspect the coupling for signs of wear, damage, or leaks.

➡️ Clean the coupling and the connected components to remove dirt and debris.

➡️ To guarantee smooth operation, lubricate the coupling’s moving components.

➡️ Replace worn-out or damaged couplings promptly.

Common issues to watch out for and troubleshooting tips

➡️ Leaks: Check for damaged seals or loose connections.

➡️ Difficulty connecting or disconnecting: Clean the coupling and lubricate the moving parts.

➡️ Latching mechanism failure: Replace the damaged component.

When and how to replace worn-out or damaged couplings

Replace worn-out or damaged couplings immediately to prevent leaks, accidents, and system failures. Follow the manufacturer’s instructions for proper replacement.

Check out these useful resources ⬇️⬇️⬇️

BSP to NPT Adapter vs. Other Converters: What to Know

Plug Square Head vs Other Plugs: What Sets It Apart

Safety Tips for Using Coupling Quick Release Systems

➡️ Best practices for safe operation and handling: Always follow the manufacturer’s instructions for safe operation.

➡️ How to prevent accidental disconnections and leaks: Ensure proper installation and avoid excessive force when connecting or disconnecting.

➡️ Importance of matching coupling specifications to system needs: Select couplings that are compatible with the fluid, pressure, and temperature of the system.

➡️ Safety checks before each use to ensure reliability: Visually inspect the coupling for damage and ensure that it is securely connected.

Conclusion

Coupling quick release systems have revolutionized the way we connect and disconnect fluid and gas lines. By offering speed, safety, and efficiency, these systems have become indispensable in a wide range of industries. By understanding the different types of couplings, their benefits, and best practices for installation and maintenance, you can optimize your operations and improve productivity.

Post time: Nov-08-2024