Cone fittings are integral components in various fluid transfer systems, facilitating secure and leak-resistant connections. They utilize a conical interface to achieve a tight seal, ensuring efficiency and safety in fluid applications.

The significance of cone fittings lies in their versatility across multiple industries. From hydraulic systems to aerospace applications, these fittings play a crucial role in maintaining seamless fluid flow and enabling the optimal functioning of machinery.

What Are Cone Fittings?

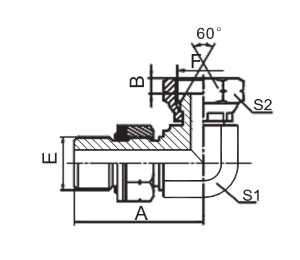

Metric Male O-Ring/BSPP Female 60°Cone Fitting

Cone Fittings, also known as conical fittings, are mechanical components designed to connect pipes or tubes together. Their conical shape allows for a secure fit, ensuring leak-free connections. These fittings are widely used in plumbing, HVAC systems, hydraulic applications, and more, making them a cornerstone of many industrial processes.

Design and Composition

A. Anatomy and Components

Cone fittings comprise main elements like the body, sleeve, nut, and cone. Understanding their design and interplay is vital for effective usage.

B. Materials Used in Cone Fittings

Materials such as stainless steel, brass, and various alloys are commonly used, imparting durability and resistance to corrosion, crucial for prolonged functionality.

Types of Cone Fittings

A. JIC (Joint Industry Council) Cone Fittings

JIC cone fittings are widely utilized in hydraulic systems, known for their excellent sealing capabilities and ease of installation.

B. BSPP (British Standard Pipe Parallel) Cone Fittings

BSPP cone fittings are prevalent in European markets, known for their robust design and compatibility with a diverse range of applications.

C. Metric Cone Fittings

Metric cone fittings, adhering to international standards, find extensive use in global industries due to their standardized sizing and reliability.

D. NPT (National Pipe Thread) Cone Fittings

NPT cone fittings are predominantly used in the United States, known for their tapered threads that create a secure, leak-resistant joint.

Advantages of Cone Fittings

A. Leak Resistance and Sealing Capabilities

The conical interface of these fittings ensures superior leak resistance and impeccable sealing, reducing the risk of fluid leakage.

B. High Pressure Tolerance

Cone fittings are designed to withstand high-pressure environments, making them ideal for applications where pressure is a critical factor.

C. Ease of Installation and Versatility

The straightforward installation process and versatility in applications make cone fittings a preferred choice, ensuring convenience and adaptability.

D. Wide Range of Applications

Cone fittings find applications across diverse sectors, including hydraulic and pneumatic systems, owing to their reliable performance and compatibility.

Applications Across Industries

➡️ Plumbing and HVAC Systems: Cone Fittings are extensively used in plumbing and HVAC systems to ensure leak-proof connections, maintaining the integrity of water and air distribution networks.

➡️ Hydraulic Systems: In hydraulic applications, Cone Fittings play a vital role in connecting pipes, hoses, and valves, allowing hydraulic systems to function seamlessly under high pressures.

➡️ Automotive Industry: Cone Fittings are integral components in automotive brake and fuel lines, providing secure connections that withstand the rigors of vehicle operation.

Proper Installation and Maintenance

A. Installation Guidelines

Proper installation techniques are essential for the effective performance of cone fittings, involving precise assembly and torque specifications.

B. Maintenance Best Practices

Regular maintenance, including inspections for wear and tear, is crucial to ensure the longevity and functionality of cone fittings in the long run.

Challenges and Troubleshooting

A. Common Challenges Faced

Understanding the potential challenges, such as fitting misalignment or thread damage, helps in anticipating and addressing issues effectively.

B. Troubleshooting Tips

Quick and efficient troubleshooting techniques assist in resolving problems promptly, minimizing downtime and optimizing performance.

Final Thought

Cone Fittings are indispensable components in various industries, serving as reliable connectors that uphold the integrity of fluid and gas systems. Their leak resistance, versatility, and ease of installation make them a preferred choice among professionals worldwide.

Post time: Nov-17-2023