Cone and thread fittings are essential components in pressure-based systems, providing a reliable and secure connection between pipes and components. Their unique design, combining a conical shape and threaded connection, ensures a tight seal even under high pressures.

In systems where pressure is a critical factor, safety is paramount. Cone and thread fittings play a crucial role in preventing leaks and ensuring the integrity of the system. Their ability to withstand high pressures without compromising the seal makes them ideal for a wide range of applications.

Why Safety is Critical in Pressure-Based Systems

Pressure-based systems, such as those found in the oil and gas industry, chemical processing, and aerospace, can have serious consequences if a leak occurs. Not only can leaks lead to property damage and environmental hazards, but they can also pose a significant risk to human safety.

The Structure and Design of Cone and Thread Fittings

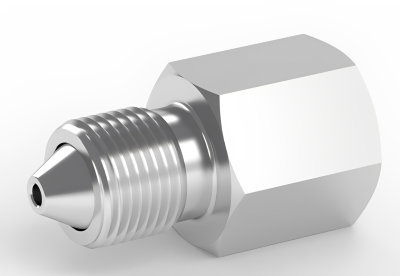

Cone and thread fittings typically consist of three main components:

➡️ The male fitting: This component has a conical end with threads cut into it.

➡️ The female fitting: This component has a matching conical bore with internal threads.

➡️ The sealing element: This can be a gasket, O-ring, or other sealing material placed between the male and female fittings to create a tight seal.

The Role of Threads in Pressure Containment

The threads on the male and female fittings serve two primary purposes:

➡️ Alignment: They ensure that the fittings are properly aligned when connected.

➡️ Engagement: The threads provide initial engagement between the fittings, creating a foundation for the conical seal.

How the Conical Shape Contributes to a Leak-Proof Seal

The conical shape of the fittings is essential for creating a leak-proof seal. As the fittings are tightened, the conical surfaces press against each other, compressing the sealing element and preventing any leakage. The conical design also helps to distribute pressure evenly across the sealing surface, enhancing the seal’s integrity.

Materials Used in Cone and Thread Fittings

Cone and thread fittings are typically made from durable materials that can withstand high pressures and harsh environments. Stainless steel is a popular choice due to its strength, corrosion resistance, and compatibility with various fluids. Other materials used in cone and thread fittings include carbon steel, brass, and nickel alloys.

Material Selection Based on Pressure and Environmental Factors

The choice of material for a cone and thread fitting depends on several factors, including:

➡️ Pressure rating: The fitting must be able to handle the maximum pressure it will encounter.

➡️ Fluid compatibility: The material must be compatible with the fluid being transported.

➡️ Environmental factors: The fitting must be resistant to corrosion, temperature extremes, and other environmental conditions.

The Benefits of Corrosion-Resistant Materials

Corrosion-resistant materials, such as stainless steel, are essential in preventing leaks and ensuring the long-term reliability of cone and thread fittings. Corrosion can weaken the material, leading to cracks and leaks. By using corrosion-resistant materials, the risk of failure is significantly reduced.

How Cone and Thread Fittings Perform Under High Pressure

The Science of Pressure Distribution in Cone and Thread Fittings

When a cone and thread fitting is subjected to high pressure, the pressure is distributed evenly across the sealing surface. This helps to prevent the seal from being overwhelmed and ensures that the fitting maintains its integrity.

How Fittings Prevent Leaks Even Under Extreme Conditions

Cone and thread fittings are designed to withstand extreme pressures without leaking. The combination of the conical shape, threaded connection, and appropriate sealing element creates a robust and reliable seal that can handle even the most demanding applications.

Pressure Ratings and the Fitting’s Ability to Handle Stress

Cone and thread fittings are available in various pressure ratings, indicating the maximum pressure they can safely handle. It is essential to select a fitting with a pressure rating that exceeds the expected operating pressure of the system.

Applications of Cone and Thread Fittings in Safety-Critical Environments

Use in Oil and Gas Industries

Cone and thread fittings are widely used in the oil and gas industry, where safety is of utmost importance. They are found in pipelines, wellheads, and other critical components, ensuring the safe and efficient transportation of oil and gas.

High-Pressure Laboratory Settings and Testing Environments

In laboratories and testing facilities, cone and thread fittings are used in high-pressure experiments and equipment. Their reliability and ability to withstand extreme pressures make them ideal for such applications.

Industrial Applications: From Chemical Processing to Aerospace

Cone and thread fittings are also used in a variety of industrial applications, including:

➡️ Chemical processing: Handling corrosive and hazardous chemicals

➡️ Aerospace: Connecting components in aircraft and spacecraft

➡️ Manufacturing: Connecting pipes and equipment in industrial processes

Read these resources ⬇️⬇️⬇️

How a Female Nut Ensures Precision and Reliability

The Role of Buttweld Stainless Elbow in Leak-Proof Pipe Connections

Installation Best Practices for Ensuring a Secure Fit

Preparing the System for Cone and Thread Installation

Before installing a cone and thread fitting, it is essential to prepare the system properly. This includes cleaning the pipe ends and ensuring that they are free of any debris or contaminants that could interfere with the seal.

Correct Tightening Techniques for Maximum Safety

Proper tightening is crucial for ensuring a secure fit and preventing leaks.While undertightening can result in leaks, overtightening can harm the fittings. It is important to follow the manufacturer’s recommendations for tightening torque.

Post-Installation Inspection and Testing for Leak Prevention

After installing a cone and thread fitting, it is essential to inspect the connection for leaks. This can be done by visually checking for any signs of leakage or by using a leak detection solution.

Advantages of Using Cone and Thread Fittings for Safety

Increased Reliability Compared to Other Fitting Types

Cone and thread fittings are known for their reliability and durability. Their unique design and construction contribute to their ability to withstand high pressures and harsh environments, making them a preferred choice in safety-critical applications.

Longevity and Minimal Maintenance

Cone and thread fittings are designed to last for many years with minimal maintenance. When properly installed and maintained, they can provide reliable service for decades.

Ensuring Safety Through Precision Engineering

The precision engineering that goes into the design and manufacture of cone and thread fittings ensures their safety and reliability. By adhering to strict quality standards, manufacturers can produce fittings that meet the highest safety requirements.

Troubleshooting Common Issues with Cone and Thread Fittings

Addressing Misalignment and Thread Damage

Misalignment and thread damage are two common issues that can lead to leaks in cone and thread fittings. If a fitting is misaligned, it may not create a proper seal. Thread damage can also prevent the fittings from engaging properly.

Preventing Over-Tightening and Its Risks

Over-tightening is a common mistake that can damage cone and thread fittings. When a fitting is over-tightened, the threads can become stripped or the sealing element can be damaged.

Fixing Leaks Caused by Improper Installation

If a cone and thread fitting is leaking, it is often due to improper installation. This can include misalignment, under-tightening, or the use of a damaged or incompatible sealing element.

The Future of Cone and Thread Fitting Technology

Innovations in Design for Greater Safety

Cone and thread fitting technology is constantly evolving. Innovations in design are being developed to enhance safety and reliability. For example, new sealing materials and improved threading techniques are being explored.

New Materials for Higher Pressure Applications

As pressure requirements increase, new materials are being developed to meet the demands of high-pressure applications. These materials are stronger, more resilient to corrosion, and more durable.

Automation and Monitoring Systems for Real-Time Safety Analysis

Automation and monitoring systems are being integrated into pressure-based systems to enhance safety. These systems can monitor the condition of cone and thread fittings in real-time, detecting potential problems before they lead to leaks or failures.

Conclusion: The Role of Cone and Thread Fittings in Pressure System Integrity

Cone and thread fittings play a critical role in ensuring the safety and integrity of pressure-based systems. Their unique design, durability, and reliability make them an essential component in a wide range of applications.

By understanding the principles of cone and thread fitting technology and following proper installation and maintenance practices, you can help to prevent leaks and ensure the safety of your system.

Post time: Oct-14-2024