Mastering compression connections is a crucial skill for any professional plumber. These connections offer a reliable and efficient way to join pipes without soldering or welding, making them ideal for various plumbing applications.

This guide will walk you through everything you need to know, from selecting the right components to achieving a secure, leak-free connection.

Before You Begin: Essential Considerations

Before diving into the process, it’s essential to consider some key factors:

A. Project Assessment:

➡️ Identifying the application: Are you working with hot or cold water lines? Gas lines require different connection methods.

➡️ Pipe size requirements: Pipes come in various diameters. Ensure you have the correct size fitting for a proper seal.

➡️ Material selection: Compression connections work with various materials like copper, PEX, and CPVC. Choose compatible materials for both the pipe and fitting to avoid leaks.

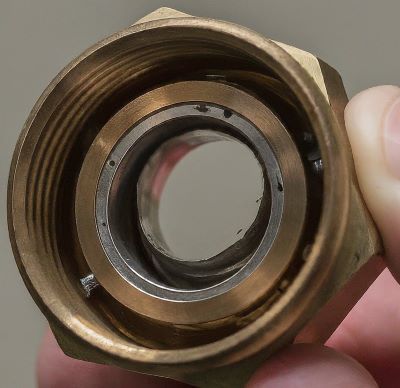

B. Choosing the Right Compression Fitting:

➡️ Understanding pressure ratings: Fittings have pressure ratings indicating the maximum water pressure they can withstand. Choose a fitting exceeding your system’s pressure.

➡️ Selecting the appropriate fitting type: Crimp, grip, and push-fit are common compression fitting types. Select the one that best suits your application and material.

➡️ Material compatibility: Fittings come in brass, stainless steel, and other materials. Ensure the fitting material is compatible with your chosen pipe material.

Step-by-Step Guide to Making a Secure Compression Connection

Now that you’ve considered the essentials, let’s get down to business:

1. Preparing the Pipe:

➡️ Cutting the pipe: Use a sharp pipe cutter to achieve a clean, square cut at the desired length.

➡️ Deburring: Remove any burrs or imperfections from the cut end using a deburring tool for a smooth connection.

➡️ (Optional for PEX): Insert the PEX insert into the pipe following the manufacturer’s instructions if required for your specific application.

2. Assembling the Fitting:

➡️ Loosen the nut and compression ring: Locate the nut and compression ring on the fitting and loosen them slightly using a wrench.

➡️ Slide the components: Slide the nut and compression ring onto the pipe, ensuring they move freely.

3. Inserting the Pipe:

➡️ Careful insertion: Carefully insert the pipe all the way into the fitting body until it reaches the stop.

4. Tightening the Connection:

➡️ Hand-tighten first: Start by hand-tightening the nut onto the fitting body as much as possible.

➡️ Wrench time: Use an appropriate wrench (adjustable or torque wrench) to further tighten the nut according to the manufacturer’s specifications. Refer to the fitting’s manual or markings for the exact torque requirement. Remember, over-tightening can damage the connection!

5. Leak Testing:

➡️ Turn on the water supply cautiously. Open the valve slowly to allow water to flow through the connection.

➡️ Inspect for leaks: Carefully examine the connection for any leaks. A small drip indicates improper tightening.

Tightening slightly if necessary:* If you find a leak, tighten the nut a very small amount using the wrench. Be mindful of over-tightening.

Pro Tips for Flawless Compression Connections

Consider this pro tips for flawless compression connections:

➡️ Right tools for the right job: Invest in proper tools like a pipe cutter and wrenches to ensure clean cuts and secure connections.

➡️ Double-check compatibility: Always double-check the pipe size and fitting compatibility before assembly.

➡️ Avoid over-tightening: Over-tightening can damage the fitting or pipe. Follow the manufacturer’s torque recommendations.

➡️ Teflon tape (optional): In specific applications, using Teflon tape on threaded connections can enhance the seal. However, always consult the manufacturer’s instructions before using tape.

➡️ Regular inspection: Regularly inspect your compression connections for signs of wear or leaks, especially after any plumbing work is done.

Conclusion

Proper compression connections are essential for a reliable and leak-free plumbing system. By following these steps and pro tips, you can confidently make secure compression connections like a pro. Remember, safety is paramount.

Always follow the manufacturer’s instructions and avoid over-tightening.

Post time: Jul-22-2024