Code 61 hydraulic fittings are integral components in hydraulic systems, providing a secure and reliable connection between various hydraulic components. These fittings play a crucial role in ensuring efficient fluid transfer and system performance. In this article, we will delve into the details of Code 61 hydraulic fittings, exploring their design, features, applications, installation, and more.

What are Code 61 Hydraulic Fittings?

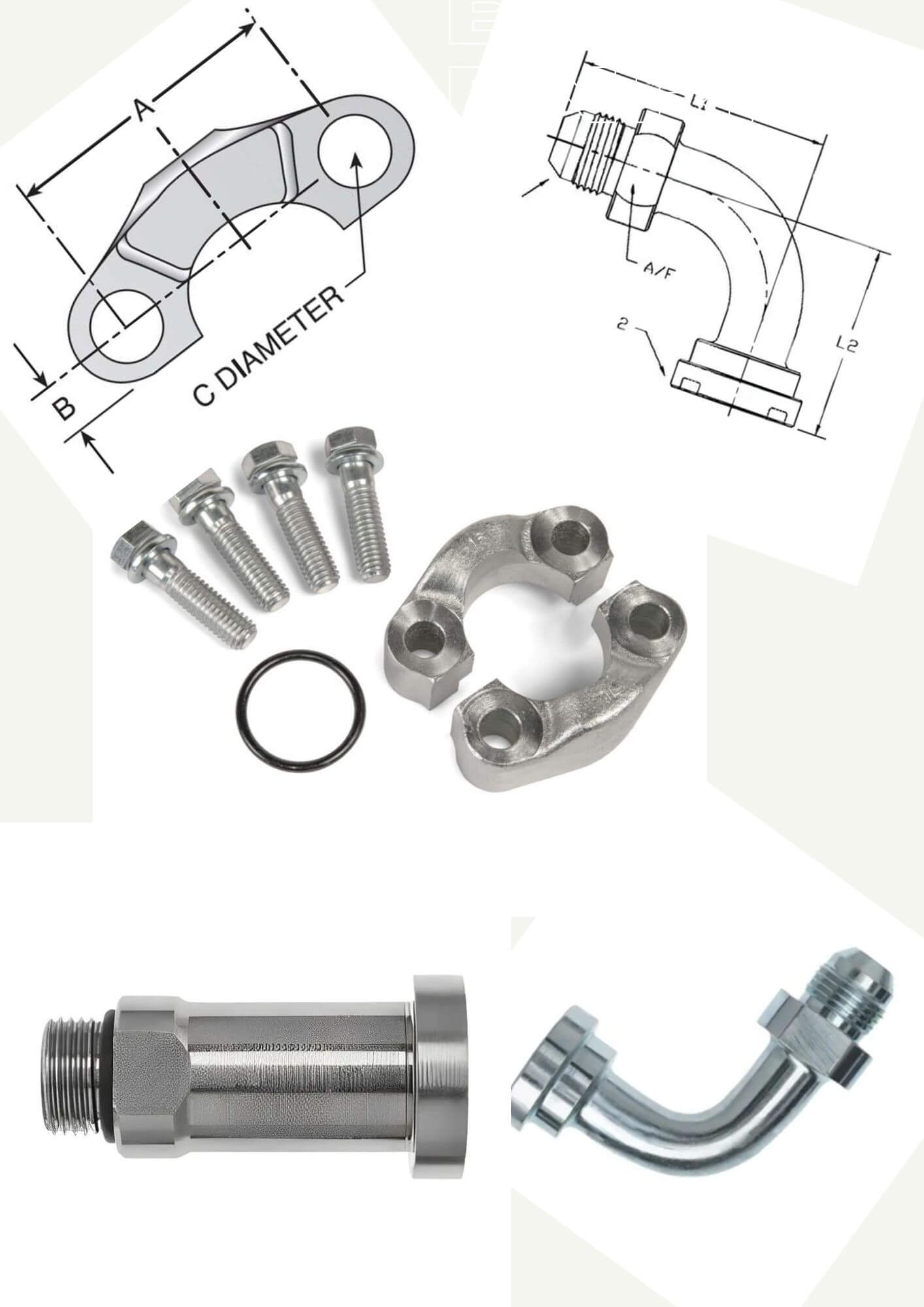

Code 61 hydraulic fittings are specifically designed to create a leak-free connection in high-pressure hydraulic systems. These fittings feature a flange connection system, which consists of a flange face and sealing surfaces. The design also incorporates O-rings or seals to provide a reliable and tight connection. Code 61 fittings are constructed using durable materials, such as steel or stainless steel, to withstand the rigors of hydraulic applications.

Working principles and advantages of Code 61 fittings include their high-pressure capabilities, which make them suitable for demanding hydraulic systems. The fittings ensure leak-free performance, minimizing fluid loss and system downtime. Additionally, Code 61 fittings are known for their ease of assembly and disassembly, facilitating maintenance and system modifications.

Several examples of Code 61 Hydraulic Fittings:

➢ 90° Male JIC Flange Hydraulic Fitting

➢ Male O-Ring Boss Flange Straight

Key Features and Components of Code 61 Hydraulic Fittings

Code 61 hydraulic fittings comprise several essential features and components that contribute to their functionality and performance. The flange design and dimensions play a crucial role in ensuring proper alignment and sealing. The flange face and sealing surfaces are precisely machined to provide a flat and smooth contact area for optimal sealing. Bolt hole patterns and sizes are standardized, allowing for easy interchangeability of fittings.

The O-ring and sealing system in Code 61 fittings is critical for preventing leaks. The fittings incorporate O-ring grooves with specific dimensions to accommodate the O-rings properly. Selecting the appropriate seal material is crucial for compatibility with different fluids and operating conditions, ensuring reliable sealing performance.

Code 61 fittings come with various port options and sizes to accommodate different hydraulic connections. Threaded ports are commonly used, while flanged ports provide a robust and secure connection. These fittings adhere to industry standards such as SAE and ISO, ensuring compatibility and interchangeability with other hydraulic components.

Applications of Code 61 Hydraulic Fittings

Code 61 hydraulic fittings find extensive applications in various industries and systems. In industrial machinery and equipment, they are commonly used in heavy-duty hydraulic systems and power generation equipment. Their high-pressure capabilities and leak-free performance make them suitable for handling demanding hydraulic applications.

In the realm of mobile machinery and construction equipment, Code 61 fittings are widely employed in vehicles such as excavators, loaders, and agricultural machinery. These fittings ensure reliable connections in the rugged and dynamic operating conditions encountered by such equipment.

Code 61 fittings also play a vital role in automotive and transportation systems, including trucks, trailers, and off-road vehicles. They provide secure connections in hydraulic brake systems, power steering systems, and other applications where reliable fluid transfer is critical.

Installation and Maintenance of Code 61 Hydraulic Fittings

Proper installation of Code 61 fittings is essential to ensure their optimal performance and longevity. Following specific guidelines, such as torque specifications for bolt tightening, helps achieve the recommended sealing and connection integrity. Proper lubrication and seating of O-rings or seals are also important to prevent leaks.

Regular inspection and maintenance practices are necessary to ensure the continued reliability of Code 61 fittings. System checks should be performed to identify any signs of leaks or damage. Worn or damaged components should be promptly replaced to prevent potential failures and downtime.

Choosing the Right Code 61 Hydraulic Fittings

When selecting Code 61 hydraulic fittings, several factors should be considered. The operating pressure and temperature requirements of the hydraulic system should match the capabilities of the fittings. Fluid compatibility is another crucial aspect to consider, ensuring that the materials of the fittings and seals are compatible with the fluids being used.

Additionally, system requirements and specifications should guide the selection process. Consulting with hydraulic experts and suppliers can provide valuable insights and assistance in choosing the right fittings for specific applications.

Conclusion

Code 61 hydraulic fittings are indispensable components in hydraulic systems, providing reliable connections for efficient fluid transfer. Their design, features, and advantages make them suitable for a wide range of applications in various industries. Proper installation, regular maintenance, and careful selection are key to ensuring the optimal performance and longevity of Code 61 fittings.

By understanding their characteristics and application requirements, hydraulic system operators can make informed decisions and harness the benefits of these versatile fittings.

Remember to always consult with hydraulic experts and suppliers to ensure the best selection and implementation of Code 61 hydraulic fittings for your specific needs.

Post time: Jul-07-2023