BSPP and BSPT threads are two widely used standards in pipe fittings, yet their differences can often cause confusion. Whether you’re working on high-pressure systems, industrial equipment, or plumbing projects, knowing when to choose BSPP or BSPT threads can save time, ensure compatibility, and prevent costly mistakes.

In this guide, we’ll unravel the key distinctions between these thread types, empowering you to make informed decisions and tackle any project with confidence.

Understanding BSP Thread Standards

BSP (British Standard Pipe) threads are a family of thread standards widely used in plumbing, hydraulics, and various industrial applications. They are known for their robustness and reliability, ensuring leak-free connections in a variety of systems.

Why BSPP and BSPT Threads Are Common in Industrial Use

BSP threads, including BSPP and BSPT, are prevalent in industrial settings due to several key advantages:

➡️ Standardization: BSP standards provide clear specifications for thread dimensions, ensuring compatibility and interchangeability of components from different manufacturers.

➡️ Strength and Durability: BSP threads are designed to withstand high pressures and stresses, making them suitable for demanding applications.

➡️ Wide Availability: BSP fittings and components are readily available in various sizes and materials, facilitating easy procurement and maintenance.

➡️Proven Reliability: With a long history of use, BSP threads have a proven track record of reliability and performance in diverse industrial settings.

What Is BSPP Thread?

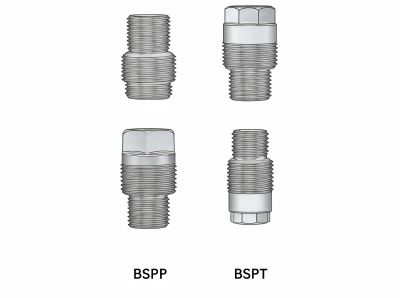

BSPP (British Standard Pipe Parallel) threads are characterized by their parallel profile. This means the thread diameter remains constant along its length.

Key Features:

➡️ Parallel Thread Form: No taper along the thread.

➡️ Relies on Seals: Sealing is achieved through the use of separate sealing elements such as washers or O-rings.

➡️ Easier Assembly and Disassembly: The parallel design allows for easier alignment and reduces the risk of thread damage during assembly and disassembly.

When to Use BSPP Threads in Practical Applications

BSPP threads are well-suited for:

➡️ Lower to Medium Pressure Applications: Where high sealing forces are not critical.

➡️ Applications Requiring Frequent Assembly and Disassembly: The parallel design minimizes thread wear and tear.

➡️ Systems Using Gaskets or O-rings for Sealing: Where a separate sealing element is preferred.

What Is BSPT Thread?

BSPT (British Standard Pipe Tapered) threads feature a tapered profile, gradually narrowing towards the end.

Key Characteristics:

➡️ Tapered Thread Form: The thread diameter decreases along its length.

➡️ Self-Sealing Mechanism: The taper creates a tight metal-to-metal seal when the threads are engaged.

➡️ Suitable for High-Pressure Applications: The tapered design provides a robust seal, even under high pressure conditions.

Common Scenarios for BSPT Thread Usage

BSPT threads are commonly used in:

➡️ High-Pressure Hydraulic Systems: Where leak-free connections are crucial.

➡️ Applications Involving Corrosive Fluids: The metal-to-metal seal can provide better resistance to leaks.

➡️ Systems Requiring a Strong, Vibration-Resistant Joint: The tapered design offers excellent resistance to loosening.

Core Differences Between BSPP and BSPT Threads

Thread Form and Angle Comparison

➡️ BSPP: Parallel thread profile.

➡️ BSPT: Tapered thread profile.

Sealing Mechanisms: Parallel vs. Tapered Threads

➡️ BSPP: Relies on external seals (washers, O-rings).

➡️ BSPT: Seals primarily through metal-to-metal contact created by the taper.

Compatibility with Various Fittings and Materials

➡️ BSPP: Compatible with a wider range of fitting materials and seal types.

➡️ BSPT: May have limitations in compatibility with certain materials and sealing methods.

Applications of BSPP and BSPT Threads

Industries That Rely on BSPP Threads

BSPP threads are widely used in:

➡️ General Plumbing and Piping: For domestic and commercial applications.

➡️ Pneumatic Systems: Where air or gas is used for power or control.

➡️ Low-Pressure Hydraulic Systems: In various industrial and manufacturing processes.

Use Cases for BSPT Threads in High-Pressure Systems

BSPT threads are essential in:

➡️ High-Pressure Hydraulics: In heavy machinery, construction equipment, and industrial presses.

➡️ Oil and Gas Industry: In pipelines, wellheads, and processing equipment.

➡️ Aerospace and Defense: In aircraft and missile systems.

Choosing the Right Thread Type for Specific Tasks

Selecting the appropriate thread type depends on several factors:

➡️ Operating Pressure: BSPT is generally preferred for high-pressure applications.

➡️ Fluid Type: Consider compatibility with sealing materials and corrosion resistance.

➡️ Frequency of Disassembly: BSPP may be more suitable for frequent maintenance.

➡️ Vibration and Shock Loads: BSPT offers better resistance to vibration and shock.

How to Identify BSPP and BSPT Threads

Visual Inspection Techniques for Quick Identification

➡️ Observe the Thread Profile: Look for the presence or absence of taper.

➡️ Check for Sealing Elements: BSPP connections often have visible seals (washers, O-rings).

Using Measurement Tools for Accurate Thread Recognition

➡️ Use Thread Gauges: To accurately measure thread dimensions and compare them to the relevant standards.

➡️ Micrometer or Caliper: Can be used to measure thread diameter and pitch.

Avoiding Common Mistakes in Thread Selection

➡️ Carefully Review Application Requirements: Ensure the chosen thread type is suitable for the intended pressure, fluid, and operating conditions.

➡️ Consult Technical Data Sheets: Refer to manufacturer specifications for compatibility and installation guidelines.

➡️ Seek Expert Advice: If unsure, consult with a qualified engineer or thread specialist.

Compatibility and Conversion Considerations

Can BSPP and BSPT Threads Be Used Together?

There is no direct interchangeability between BSPP and BSPT threads. Attempting to connect them can lead to leaks, damage, and system failure.

Adapters and Solutions for Thread Conversion

To connect components with different thread types, use appropriate adapters:

➡️ BSPP to BSPT Adapters: Convert BSPP connections to BSPT.

➡️ BSPT to BSPP Adapters: Convert BSPT connections to BSPP.

Tips for Selecting the Right Thread for Your Needs

Factors to Consider: Pressure, Seal Type, and Material

➡️ Operating Pressure: Determine the maximum and minimum pressures the system will experience.

➡️ Fluid Type: Consider the compatibility of the thread type and sealing materials with the fluid.

➡️ Material Compatibility: Ensure the thread materials are compatible with the fluid and operating environment.

Expert Advice on Making the Best Choice

➡️ Consult with Engineers and Specialists: Seek expert guidance on thread selection for critical applications.

➡️ Review Industry Standards: Adhere to relevant industry standards and best practices.

➡️ Consider Long-Term Maintenance: Choose a thread type that will minimize maintenance requirements over the system’s lifetime.

Conclusion

Understanding the key differences between BSPP and BSPT threads is crucial for ensuring the success of any plumbing, hydraulic, or industrial project. By carefully considering the factors outlined in this blog post, you can make informed decisions about thread selection, leading to reliable, leak-free, and long-lasting connections.

Remember, choosing the right thread type is not just about compatibility; it’s about optimizing performance, minimizing maintenance, and ensuring the overall success of your project.

Post time: Jan-03-2025