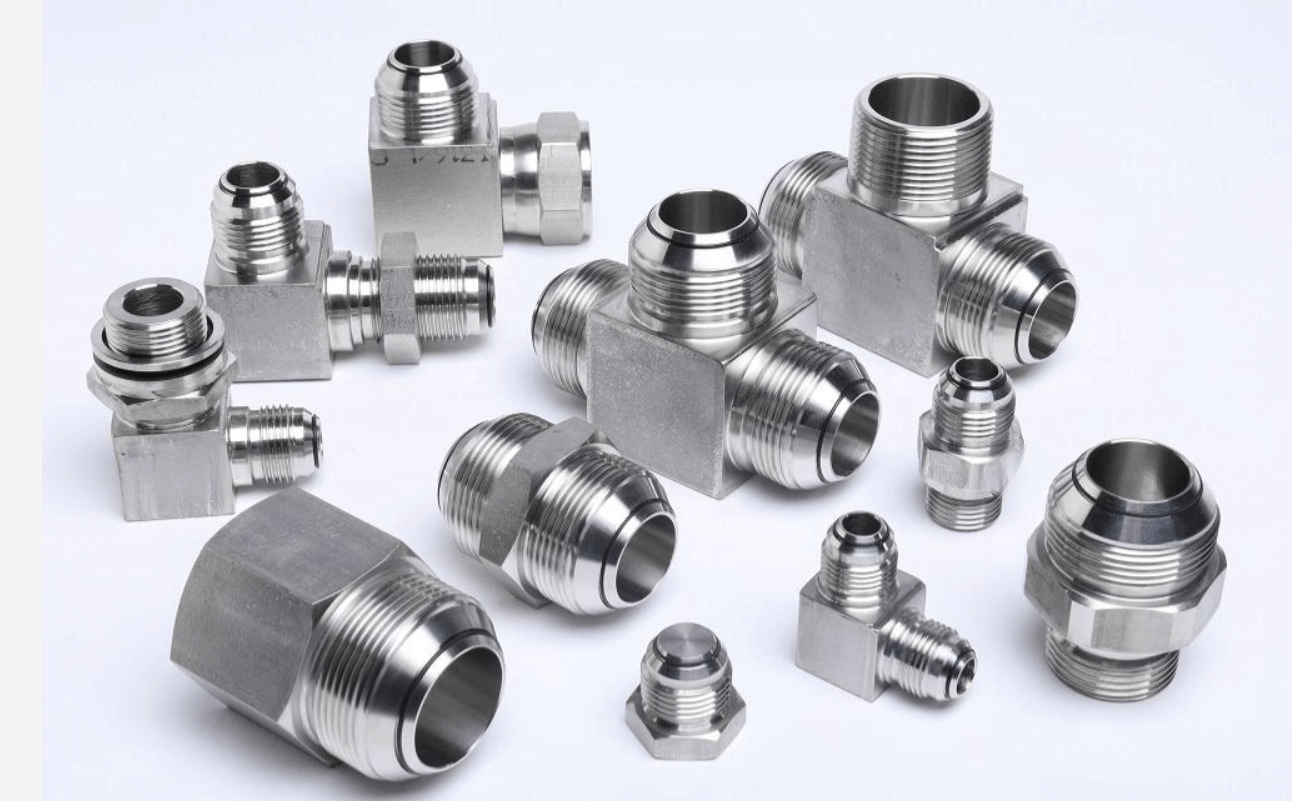

Hydraulic fittings are vital components in hydraulic systems, ensuring proper fluid transfer, sealing, and connection integrity. When it comes to hydraulic fittings, the British Standard (BS) holds significant importance due to its long-standing reputation for quality and reliability.

In this article, we will explore the world of British Standard hydraulic fittings, their types, advantages, considerations for selection, installation and maintenance best practices, comparisons with other standards, sourcing options, and the future trends shaping the industry.

What is British Standard (BS) Hydraulic Fittings?

British Standard hydraulic fittings adhere to a set of regulations and standards established by the British Standards Institution (BSI). These fittings are recognized globally for their high quality, precision engineering, and strict adherence to safety guidelines. The utilization of BS hydraulic fittings ensures compatibility, reliability, and longevity of hydraulic systems, making them a preferred choice in industries ranging from manufacturing and construction to automotive and aerospace.

Types of British Standard Hydraulic Fittings:

BSPP (British Standard Pipe Parallel) fittings:

BSPP fittings feature parallel threads that create a reliable connection through mechanical tightening. These fittings are widely used in industries such as agriculture, mining, and industrial automation.

BSPT (British Standard Pipe Taper) fittings:

BSPT fittings have tapered threads that provide a secure seal through the use of thread sealing compounds. They are commonly found in plumbing and pneumatic applications.

BSF (British Standard Fine) fittings:

BSF fittings utilize fine threads and are primarily employed in applications requiring high vibration resistance, such as aerospace and marine industries.

BSW (British Standard Whitworth) fittings:

BSW fittings feature a coarse thread design and find applications in heavy machinery, construction equipment, and plumbing.

Key Considerations for Selecting British Standard Fittings

When choosing British Standard hydraulic fittings, several factors need to be considered:

➢ Compatibility with the hydraulic system’s operating conditions and components.

➢ Material selection based on environmental factors and corrosion resistance requirements.

➢ Pressure ratings and temperature limitations to ensure safe operation within specified parameters.

➢ Thread type and sealing mechanisms, considering factors like ease of assembly, disassembly, and leak prevention.

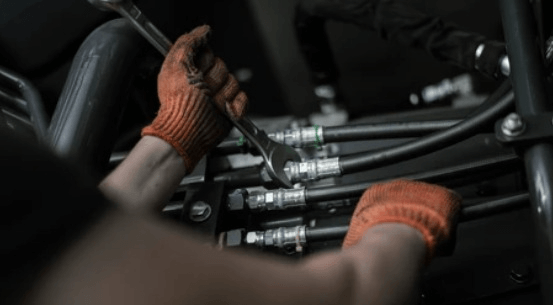

Installation and Maintenance of British Standard Fittings

Proper installation techniques are crucial to achieving optimal performance and longevity of hydraulic systems using British Standard fittings. It is essential to follow recommended torque values, use suitable thread sealants, and ensure cleanliness during installation. Routine maintenance and inspections are also necessary to detect any signs of wear, leakage, or degradation in the fittings, allowing for timely repairs or replacements.

Comparing British Standard Fittings with Other Standards

SAE (Society of Automotive Engineers) fittings:

While SAE fittings share similarities with British Standard fittings, they have different thread designs and sealing methods. SAE fittings are commonly used in automotive applications, whereas British Standard fittings find wider use across various industries.

DIN (Deutsches Institut für Normung) fittings:

DIN fittings, widely used in Europe, have their own set of standards and specifications. While DIN and BS fittings may share similar functionalities, they differ in thread profiles, sealing methods, and regional preferences.

Where to Source British Standard Hydraulic Fittings?

To ensure the quality and authenticity of British Standard hydraulic fittings, it is advisable to source them from authorized manufacturers and suppliers. Reputable online platforms and marketplaces can also provide access to a wide range of BS fittings, enabling customers to make informed purchasing decisions based on their specific requirements.

Future Trends and Innovations in British Standard Hydraulic Fittings

The hydraulic fittings industry continues to evolve, driven by technological advancements and sustainability initiatives. Future trends include innovative designs that enhance performance, the integration of smart technologies for real-time monitoring, and the development of eco-friendly materials and manufacturing processes to reduce environmental impact.

Conclusion

In conclusion, British Standard hydraulic fittings play a vital role in ensuring the reliability and performance of hydraulic systems. Their adherence to strict quality standards, compatibility with various applications, and global recognition make them a preferred choice across industries. By considering factors like compatibility, materials, pressure ratings, and proper installation, hydraulic system operators can maximize the benefits of British Standard fittings while ensuring safety and longevity.

As the industry progresses, staying informed about advancements and embracing emerging trends will further enhance hydraulic system efficiency and sustainability.

Post time: Jul-07-2023