Are You Working in Hydraulics? Chances are that f so, JIC fittings may already be familiar to you. JICs are popular hydraulic fittings used to connect hoses, tubes, and pipes within hydraulic systems; their installation process is easy while remaining durable and reliable. Here we cover everything you need to know about them: what they are, their working principles, how they function as well as why their significance should not be ignored.

What are JIC Fittings?

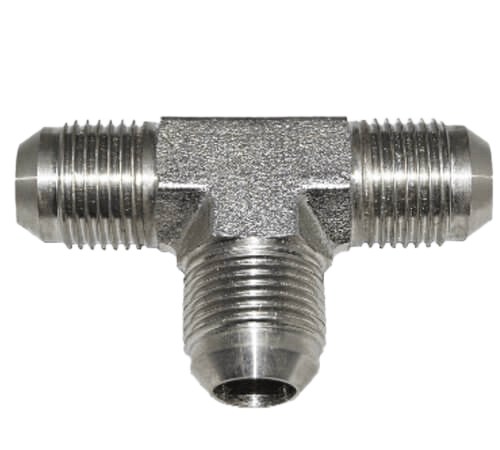

JIC fittings (Joint Industry Council fittings) are popular hydraulic connections used to connect hoses, tubes, and pipes in hydraulic systems. Easy to install, durable, and reliable - JIC fittings feature a 37-degree flare angle which creates a metal-to-metal seal ideal for high pressure applications.

Why are JIC Fittings Important?

JIC fittings are essential components in hydraulic systems because they offer reliable and leak-free connections. Easy installation helps save both time and money. Furthermore, their metal-to-metal seal makes JIC fittings an excellent option for high pressure applications - common among hydraulic industry operators.

Types of JIC Fittings:

JIC fittings come in two varieties, male and female. Male JICs feature straight threads and 37-degree flare seats; on the other hand, female versions feature straight threads with no flare seat. Male fittings tend to be used on hoses or tubes while their counterparts can also be found on ports.

How do JIC Fittings Work?

JIC fittings work by creating a metal-to-metal seal between their components. Their 37-degree flare angle creates an effective seal, ideal for high pressure applications. JIC fittings consist of two parts: the fitting body and its matching nut, both featuring 37-degree flare angles on their ends; when tightening their respective nuts compress the flare against each other to form an airtight seal against one another and tightening creates a tight seal against its components.

JIC Fittings for Fluid Power System:

Fluid power systems are utilized by various industries and applications to transmit and regulate power through pressurized fluids, typically pumps, valves, actuators and fittings. Fittings play an integral part in fluid power systems by providing connections between components; one key factor that makes JIC fittings ideal for this application is their robust construction.

JIC Fittings are High-Pressure Fluid Conveying:

JIC fittings excel at conveying fluids at high pressure due to their robust design and high-pressure capability, creating secure leak-free connections under high pressure by means of its 37-degree flare angle and metal-to-metal seal that withstands high pressure - thus preventing fluid leakage. These fittings are easy to install and maintain due to their standardized design which enables replacement or interchangeability between fittings meeting similar standards.

Advantages of JIC Fittings:

➢ Easy to install

➢ Durable and reliable

➢ Metal-to-metal seal is ideal for high-pressure applications

➢ Leak-free connection

➢ Versatile

Disadvantages of JIC Fittings:

➢ Limited to high-pressure applications

➢ More expensive than other types of fittings

➢ Require special tools for installation

How to Install JIC Fittings:

Installing JIC fittings is relatively easy, but it does require some special tools. Here's how to install JIC fittings:

➢ Cut the hose to the desired length.

➢ Slide the nut onto the hose.

➢ Slide the fitting body onto the hose.

➢ Insert the hose into the fitting body until it bottoms out.

➢ Reinforce the nut using a wrench until it's tight.

➢ Use a JIC fitting tool to tighten the nut to the correct torque.

Conclusion:

JIC fittings are a key part of hydraulic systems. Offering reliable and leak-free connections that can withstand high-pressure applications, JIC fittings are easy to install, durable and dependable; making them popular choices among hydraulic system designers and operators. Understanding what JIC fittings are can provide valuable insight into their functionality - with this comprehensive guide you should now have an improved knowledge about this component and why they could benefit your hydraulic system.

Post time: May-26-2023