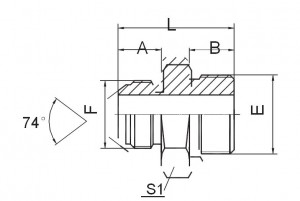

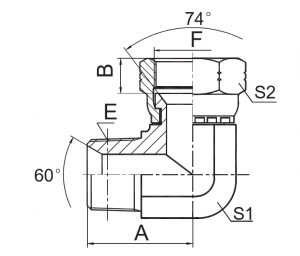

1. Male 74° Cone / BSP Male Flat-Face – Top-quality hydraulic fitting for fluid connectors and other OEM mechanical parts.

2. Made with a wide range of high-quality materials, including 1045, 1010, 1020, 1035, and stainless steel for hydraulic fluid connectors, as well as brass, steel, aluminum, and copper for other OEM mechanical parts.

3. Manufactured using advanced process machines, including CNC machines, Turning and Drilling machines, and Pressed Rolling machines, to ensure precision and accuracy in every product.

4. Passed through a set of inspecting and measuring facilities, such as a Shape Analyzer and Projector, to ensure the highest standards of quality control.

|

PART NO.

|

THREAD | DIMENSIONS | ||||

| E | F | A | B | L | S1 | |

| S1JB-06F | 9/ 16″X18 | G3/8″X19 | 14. 1 | 1 1.5 | 31.6 | 19 |

| S1JB-08F | 3/4″X16 | G1/2″X14 | 16.7 | 14 | 38.7 | 22 |

| S1JB-10F | 7/8″X14 | G5/8″X14 | 19.3 | 14.5 | 41.8 | 24 |

| S1JB-12F | 1.1/ 16″X12 | G3/4″X14 | 21.9 | 15.5 | 47.4 | 30 |

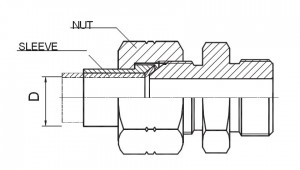

Male 74° Cone / BSP Male Flat-Face hydraulic fitting, a top-quality component designed for fluid connectors and other OEM mechanical parts. We are a professional manufacturer specializing in hydraulic hose fittings, adaptors, and various mechanical parts.

Our commitment to providing exceptional products is reflected in the materials we use. Our Male 74° Cone / BSP Male Flat-Face fitting is crafted with a wide range of high-quality materials. For hydraulic fluid connectors, we primarily utilize 1045, 1010, 1020, 1035, and stainless steel, ensuring durability and optimal performance. In addition, for other OEM mechanical parts, we incorporate materials such as brass, steel, aluminum, and copper, offering versatility and reliability for various applications.

To ensure precision and accuracy, we operate within a well-equipped facility spanning 3000 square meters. Our processing workshop houses advanced machinery, including CNC machines, Turning and Drilling machines, and Pressed Rolling machines. These cutting-edge tools enable us to deliver products that meet stringent quality standards.

At Sannke, quality control is of utmost importance. We have implemented a comprehensive set of inspecting and measuring facilities, including Shape Analyzer and Projector. Every fitting undergoes thorough inspection to ensure it meets our high standards of excellence.

Please note that the product pictures displayed on our website showcase our machining capabilities and product range. We also offer custom machining services based on customer-provided drawings or samples.

For all your hydraulic fitting needs, Sannke is the best choice. As the leading hydraulic fitting factory, we prioritize customer satisfaction and provide top-quality products. Feel free to contact us for more information or to discuss your specific requirements.

-

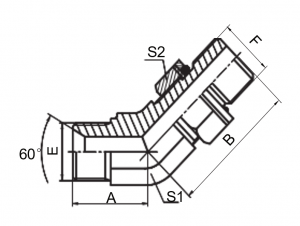

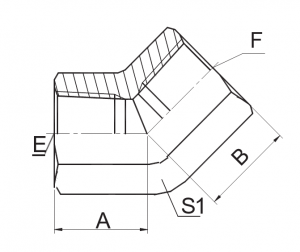

High-Quality 45° Elbow BSP Male 60° Seat | Metr...

-

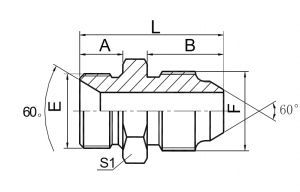

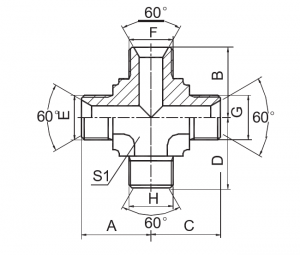

BSP Male 60° Seat / JIS Metric Male 60° Cone Fi...

-

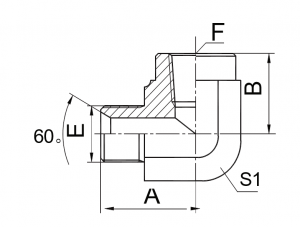

90° BSP Male 60° Seat / BSPT Female Fitting | W...

-

45° BSPT Female Fittings | Stainless Steel, Car...

-

BSP Male 60° Seat | Excellent Fitting Solution

-

90° NPT Male / JIC Female 74° Seat Adapter | Du...