1. Choose from a range of connector body materials and O-ring options to suit your specific requirements. Available materials include carbon steel, 304 stainless steel, 316L stainless steel, and 316Ti stainless steel, paired with NBR, Viton SR, Viton SV, or Viton SY O-rings.

2. Opt for Durakote plating (suffix ZD) on carbon steel connectors for enhanced protection, providing up to 720 hours of resistance against red rust.

3. The zinc-nickel plating option (suffix ZN) for carbon steel connectors ensures extended durability with up to 1000 hours of white rust protection.

4. These connectors adhere to the BOSS L-Series ISO 11926-3 standard, guaranteeing top-notch quality and performance in hydraulic applications.

5. With various material, O-ring, and plating choices, our JIC Male 74° Cone / SAE O-Ring Boss L Series connectors offer flexibility and durability to meet your diverse hydraulic connection needs.

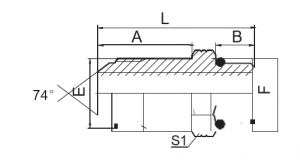

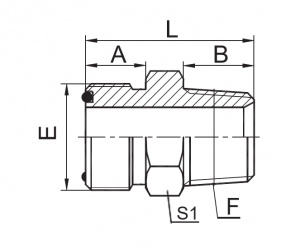

|

PART NO.

|

THREAD | DIMENSIONS | |||||

| E | F | F | A | B | L | S1 | |

| S1JO-04L | 7/16"X20 | 7/16"X20 | O904 | 35 | 9.1 | 50.5 | 14 |

| S1JO-05L | 1/2"X20 | 1/2"X20 | O905 | 37 | 9.1 | 52.5 | 17 |

| S1JO-06L | 9/16"X18 | 9/16"X18 | O906 | 39 | 9.9 | 55.5 | 17 |

| S1JO-08L | 3/4"X16 | 3/4"X16 | O908 | 48 | 11 .1 | 67.5 | 22 |

| S1JO-10L | 7/8"X14 | 7/8"X14 | O910 | 53 | 12.7 | 76 | 27 |

| S1JO-12L | 1.1/16"X12 | 1.1/16"X12 | O912 | 63 | 15.1 | 89 | 32 |

| S1JO-16L | 1.5/16"X12 | 1.5/16"X12 | O916 | 72 | 15.1 | 100 | 38 |

| S1JO-20L | 1.5/8"X12 | 1.5/8"X12 | O920 | 88.1 | 15.1 | 118 | 50 |

| Note: Nut and sleeve should be ordered separately. The nut NB200 and sleeve NB500 is suitable for metric tube, the nut NB200 and sleeve NB300 is suitable for inch tube. | |||||||

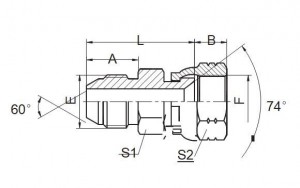

JIC Male 74° Cone / SAE O-Ring Boss L Series connectors, offering flexibility and durability to meet your diverse hydraulic connection needs.

Customization is at the core of these connectors, as you can choose from a range of connector body materials and O-ring options to suit your specific requirements. Available materials include carbon steel, 304 stainless steel, 316L stainless steel, and 316Ti stainless steel, paired with NBR, Viton SR, Viton SV, or Viton SY O-rings. This selection ensures that you can find the perfect fit for your application, whether it requires high corrosion resistance or compatibility with specific fluids.

For enhanced protection on carbon steel connectors, you have the option to opt for Durakote plating (suffix ZD), providing up to 720 hours of resistance against red rust. Alternatively, the zinc-nickel plating option (suffix ZN) offers up to 1000 hours of white rust protection, ensuring extended durability in harsh conditions.

Adhering to the BOSS L-Series ISO 11926-3 standard, these connectors guarantee top-notch quality and performance in hydraulic applications. You can trust in their reliability and precision engineering to deliver optimal performance in critical hydraulic systems.

In conclusion, our JIC Male 74° Cone / SAE O-Ring Boss L Series connectors offer a wide range of material, O-ring, and plating choices, allowing for customization and adaptability to your specific hydraulic connection needs. With durability, corrosion resistance, and adherence to industry standards, these connectors provide reliable performance for diverse hydraulic applications.

For the best hydraulic fitting factory experience, look no further than Sannke. We are committed to excellence and dedicated to providing top-quality hydraulic fittings. For further inquiries or to place an order, please don't hesitate to contact us.