JIC hydraulic fittings are engineered based on the installation design standard ISO 12151-5, which ensures that they can be installed efficiently and effectively. These fittings are combined with the design standards of ISO 8434-2 and SAE J514, which ensure that they meet the highest quality and safety standards.

The design of the tail and sleeve of the hydraulic core is based on Parker’s 26 series, 43 series, 70 series, 71 series, 73 series, and 78 series, which are some of the best in the industry. This means that these fittings are able to perfectly match and replace Parker’s hose fitting products, providing users with a reliable and efficient solution for their hydraulic system needs.

The JIC hydraulic fittings are suitable for a wide range of applications, including hydraulic systems in the automotive, aerospace, and industrial sectors. They are designed to withstand high pressure and temperature conditions, and their durability ensures that they can provide long-term performance in harsh environments.

-

45° Elbow SAE Code 62 Flange Head | Efficient Crimping for Swift Assembly

Enhance your hydraulic setup with 45° Elbow SAE Code 62 Flange Head. Swift assembly, No-Skive technology, and Chromium-6 free plating for durability.

-

SAE Code 62 Flange Head | Permanent Crimp Style

Elevate your hydraulic system with SAE Code 62 Flange Head. Swift assembly, No-Skive technology, and Chromium-6 free plating for durability.

-

SAE Code 61 Flange Head – 110° Elbow | Material Versatility for Customization

Optimize your hydraulic system with SAE Code 61 Flange Head – 110° Elbow. Choose from durable materials for easy and cost-effective operations. Compatible with SAE100 R12 hoses.

-

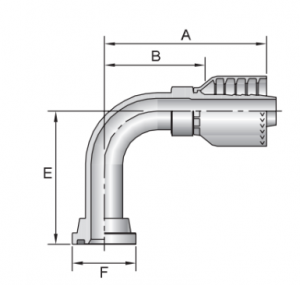

SAE Code 61 Flange Head – 90° Elbow – Long Drop | Versatile Thread Forms

Elevate your hydraulic connections with SAE Code 61 Flange Head – 90° Elbow – Long Drop. Versatile material options for efficient and cost-effective operations. Compatible with SAE100 R12 hoses.

-

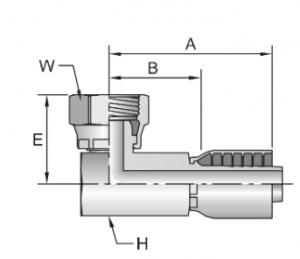

Female BSP Parallel Pipe – Swivel – 90° Elbow – Block Type – (60° Cone) | No-Skive Technology

Discover precision with Female BSP Parallel Pipe – Swivel – 90° Elbow – Block Type (60° Cone). Elevate your hydraulic system with this specialized fitting.

-

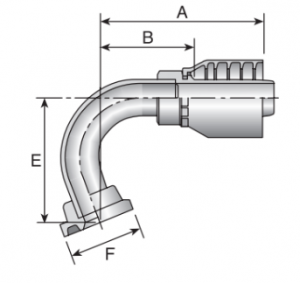

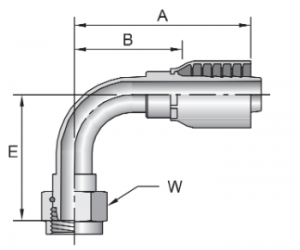

Female BSP Parallel Pipe – Swivel – 90° Elbow – (60° Cone) | Chromium-6 Free Plating

Experience efficiency with Female BSP Parallel Pipe – Swivel – 90° Elbow (60° Cone). Quick assembly, NO-SKIVE design, Chromium-6 free. Ideal for Hydraulic Braided, Light Spiral, Specialty, Suction, and Return Hoses.

-

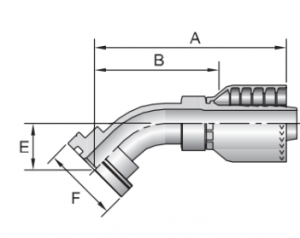

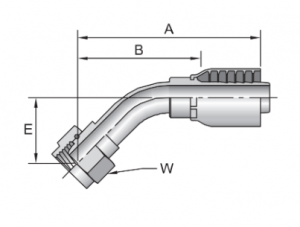

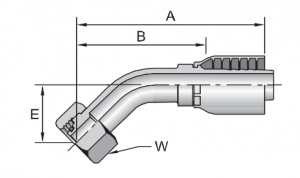

Swivel Female BSP Parallel Pipe – 45° Elbow – (60° Cone) | Versatile Configurations

Explore versatility with Swivel Female BSP Parallel Pipe – 45° Elbow – (60° Cone). Permanent crimp design, wide end configurations, and compatible with various hoses.

-

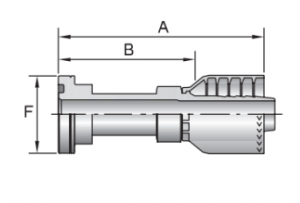

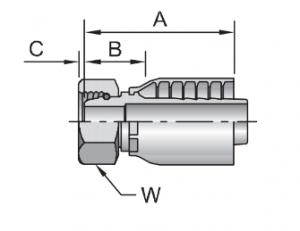

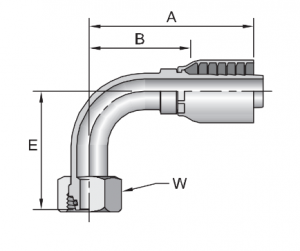

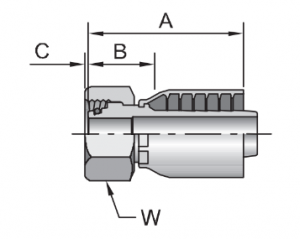

Swivel Female BSP Parallel Pipe – (60° Cone) | No-Skive Advantage

Opt for reliability with Swivel Female BSP Parallel Pipe – (60° Cone). Permanent crimp design, NO-SKIVE assembly, Chromium-6 free. Ideal for Hydraulic Braided, Light Spiral, Specialty, Suction, and Return Hoses.

-

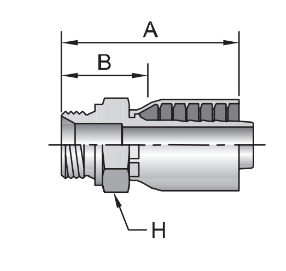

Rigid Male BSP Parallel Pipe – (60° Cone) | Material Options for Flexibility

Discover Rigid Male BSP Parallel Pipe – (60° Cone)! Options include carbon steel, 304, 316. Versatile thread forms and NO-SKIVE design for easy operation.

-

Swivel Female Metric S – 90° Elbow – (24° Cone with O-Ring) | Swivel Flexibility

Explore durable Swivel Female Metric S – 90° Elbow – (24° Cone with O-Ring), crafted from high-quality steel.

-

Swivel Female Metric S – 45° Elbow (24° Cone with O-Ring) | Swivel Precision

Elevate connections with Swivel Female Metric S – 45° Elbow (24° Cone with O-Ring) fittings. Crimped and swivel for precision.

-

24° Cone with O-Ring Swivel Female Metric S | Cone Stability

Discover precision with 24° Cone with O-Ring Swivel Female Metric S fitting. Straight, swivel, and crimped for seamless connections.