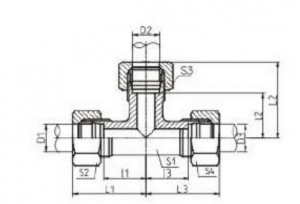

1. High-quality Equal Tees for hydraulic fittings.

2. Designed for industrial, engineer truck, and agricultural machinery applications.

3. Working pressure options: 3000PSI, 6000PSI, and 9000PSI.

4. Available in carbon steel or customizable stainless steel body material.

5. Zinc-plated surface treatment for enhanced durability and corrosion resistance.

|

PART NO.

|

THREAD | TUBE O.D. | DIMENSIONS |

MPa

|

|||||||||||||

| E | F | G | D1 | D2 | D3 | 1l | 2l | 3l | L1 | L2 | L3 | S1 | S2 | S3 | S4 | ||

| SAC- 12- 14- 12 | M12X1.5 | M14X1.5 | M12X1.5 | 6 | 8 | 6 | 14 | 14 | 14 | 29 | 29 | 29 | 14 | 14 | 17 | 14 |

25

L |

| SAC- 12- 16- 12 | M12X1.5 | M16X1.5 | M12X1.5 | 6 | 10 | 6 | 15 | 15 | 15 | 30 | 30 | 30 | 14 | 14 | 19 | 14 | |

| SAC- 12- 16- 16 | M12X1.5 | M16X1.5 | M16X1.5 | 6 | 10 | 10 | 15 | 15 | 15 | 30 | 30 | 30 | 14 | 14 | 19 | 19 | |

| SAC- 14- 12- 14 | M14X1.5 | M12X1.5 | M14X1.5 | 8 | 6 | 8 | 14 | 14 | 14 | 29 | 29 | 29 | 14 | 17 | 14 | 17 | |

| SAC- 14- 14- 18 | M14X1.5 | M14X1.5 | M18X1.5 | 8 | 8 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 17 | 17 | 22 | |

| SAC- 14- 16- 14 | M14X1.5 | M16X1.5 | M14X1.5 | 8 | 10 | 8 | 15 | 15 | 15 | 30 | 30 | 30 | 14 | 17 | 19 | 17 | |

| SAC- 14- 18- 14 | M14X1.5 | M18X1.5 | M14X1.5 | 8 | 12 | 8 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 17 | 22 | 17 | |

| SAC- 16- 12- 16 | M16X1.5 | M12X1.5 | M16X1.5 | 10 | 6 | 10 | 15 | 15 | 15 | 30 | 30 | 30 | 14 | 19 | 14 | 19 | |

| SAC- 16- 14- 16 | M16X1.5 | M14X1.5 | M16X1.5 | 10 | 8 | 10 | 15 | 15 | 15 | 30 | 30 | 30 | 14 | 19 | 17 | 19 | |

| SAC- 16- 16- 18 | M16X1.5 | M16X1.5 | M18X1.5 | 10 | 10 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 19 | 19 | 22 | |

| SAC- 16- 16-26 | M16X1.5 | M16X1.5 | M26X1.5 | 10 | 10 | 18 | 24 | 24 | 24 | 39 | 39 | 40 | 24 | 19 | 19 | 32 | |

| SAC- 16- 18- 16 | M16X1.5 | M18X1.5 | M16X1.5 | 10 | 12 | 10 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 19 | 22 | 19 | |

| SAC- 16- 18- 18 | M16X1.5 | M18X1.5 | M18X1.5 | 10 | 12 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 19 | 22 | 22 | |

| SAC- 16-22- 16 | M16X1.5 | M22X1.5 | M16X1.5 | 10 | 15 | 10 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 19 | 27 | 19 | |

| SAC- 16-26-26 | M16X1.5 | M26X1.5 | M26X1.5 | 10 | 18 | 18 | 24 | 24 | 24 | 39 | 40 | 40 | 24 | 19 | 32 | 32 | |

| SAC- 18- 12- 18 | M18X1.5 | M12X1.5 | M18X1.5 | 12 | 6 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 22 | 14 | 22 | |

| SAC- 18- 14- 18 | M18X1.5 | M14X1.5 | M18X1.5 | 12 | 8 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 22 | 17 | 22 | |

| SAC- 18- 16- 18 | M18X1.5 | M16X1.5 | M18X1.5 | 12 | 10 | 12 | 17 | 17 | 17 | 32 | 32 | 32 | 17 | 22 | 19 | 22 | |

| SAC- 18- 18-22 | M18X1.5 | M18X1.5 | M22X1.5 | 12 | 12 | 15 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 22 | 22 | 27 | |

| SAC- 18-22- 18 | M18X1.5 | M22X1.5 | M18X1.5 | 12 | 15 | 12 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 22 | 27 | 22 | |

| SAC- 18-22-22 | M18X1.5 | M22X1.5 | M22X1.5 | 12 | 15 | 15 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 22 | 27 | 27 | |

| SAC- 18-22-30 | M18X1.5 | M22X1.5 | M30X2 | 12 | 15 | 22 | 28 | 28 | 28 | 43 | 43 | 44 | 27 | 22 | 27 | 36 | |

| SAC- 18-26- 18 | M18X1.5 | M26X1.5 | M18X1.5 | 12 | 18 | 12 | 24 | 24 | 24 | 39 | 40 | 39 | 24 | 22 | 32 | 22 | |

| SAC-22- 12-22 | M22X1.5 | M12X1.5 | M22X1.5 | 15 | 6 | 15 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 27 | 14 | 27 | |

| SAC-22- 16-22 | M22X1.5 | M16X1.5 | M22X1.5 | 15 | 10 | 15 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 27 | 19 | 27 | |

| SAC-22- 18-22 | M22X1.5 | M18X1.5 | M22X1.5 | 15 | 12 | 15 | 21 | 21 | 21 | 36 | 36 | 36 | 19 | 27 | 22 | 27 | |

| SAC-22-22-30 | M22X1.5 | M22X1.5 | M30X2 | 15 | 15 | 22 | 28 | 28 | 28 | 43 | 43 | 44 | 27 | 27 | 27 | 36 | |

| SAC-22-26-22 | M22X1.5 | M26X1.5 | M22X1.5 | 15 | 18 | 15 | 24 | 24 | 24 | 39 | 40 | 39 | 24 | 27 | 32 | 27 | |

| SAC-26- 16-26 | M26X1.5 | M16X1.5 | M26X1.5 | 18 | 10 | 18 | 23.5 | 24 | 23.5 | 40 | 39 | 40 | 24 | 32 | 19 | 32 | |

| SAC-26- 18-26 | M26X1.5 | M18X1.5 | M26X1.5 | 18 | 12 | 18 | 23.5 | 24 | 23.5 | 40 | 39 | 40 | 24 | 32 | 22 | 32 | |

| SAC-26-22-26 | M26X1.5 | M22X1.5 | M26X1.5 | 18 | 15 | 18 | 24 | 24 | 24 | 40 | 39 | 40 | 24 | 32 | 27 | 32 | |

| SAC-26-26-30 | M26X1.5 | M26X1.5 | M30X2 | 18 | 18 | 22 | 27.5 | 27.5 | 27.5 | 44 | 44 | 44 | 27 | 32 | 32 | 36 |

16

L |

| SAC-26-30-30 | M26X1.5 | M30X2 | M30X2 | 18 | 22 | 22 | 27.5 | 27.5 | 27.5 | 44 | 44 | 44 | 27 | 32 | 36 | 36 | |

| SAC-30- 16-30 | M30X2 | M16X1.5 | M30X2 | 22 | 10 | 22 | 27.5 | 28 | 27.5 | 44 | 43 | 44 | 27 | 36 | 19 | 36 | |

| SAC-30- 18-30 | M30X2 | M18X1.5 | M30X2 | 22 | 12 | 22 | 27.5 | 28 | 27.5 | 44 | 43 | 44 | 27 | 36 | 22 | 36 | |

| SAC-30-22-30 | M30X2 | M22X1.5 | M30X2 | 22 | 15 | 22 | 27.5 | 28 | 27.5 | 44 | 43 | 44 | 27 | 36 | 27 | 36 | |

| SAC-30-26-30 | M30X2 | M26X1.5 | M30X2 | 22 | 18 | 22 | 27.5 | 27.5 | 27.5 | 44 | 44 | 44 | 27 | 36 | 32 | 36 | |

| SAC-30-30-36 | M30X2 | M30X2 | M36X2 | 22 | 22 | 28 | 30.5 | 30.5 | 30.5 | 47 | 47 | 47 | 36 | 36 | 36 | 41 | |

| SAC-36- 16-36 | M36X2 | M16X1.5 | M36X2 | 28 | 10 | 28 | 30.5 | 31 | 30.5 | 47 | 46 | 47 | 36 | 41 | 19 | 41 | |

| SAC-36- 18-36 | M36X2 | M18X1.5 | M36X2 | 28 | 12 | 28 | 30.5 | 31 | 30.5 | 47 | 46 | 47 | 36 | 41 | 22 | 41 | |

| SAC-36-22-36 | M36X2 | M22X1.5 | M36X2 | 28 | 15 | 28 | 30.5 | 31 | 30.5 | 47 | 46 | 47 | 36 | 41 | 27 | 41 | |

| SAC-36-26-36 | M36X2 | M26X1.5 | M36X2 | 28 | 18 | 28 | 30.5 | 30.5 | 30.5 | 47 | 47 | 47 | 36 | 41 | 32 | 41 | |

| SAC-36-30-36 | M36X2 | M30X2 | M36X2 | 28 | 22 | 28 | 30.5 | 30.5 | 30.5 | 47 | 47 | 47 | 36 | 41 | 36 | 41 | |

| SAD- 16- 16-20 | M16X1.5 | M16X1.5 | M20X1.5 | 8 | 8 | 12 | 22 | 22 | 22 | 37 | 37 | 38 | 17 | 19 | 19 | 24 |

63

S |

| SAD- 18- 14- 18 | M18X1.5 | M14X1.5 | M18X1.5 | 10 | 6 | 10 | 17.5 | 18 | 17.5 | 34 | 33 | 34 | 17 | 22 | 17 | 22 | |

| SAD-20- 16-20 | M20X1.5 | M16X1.5 | M20X1.5 | 12 | 8 | 12 | 21.5 | 22 | 21.5 | 38 | 37 | 38 | 17 | 24 | 19 | 24 | |

| SAD-20- 18-20 | M20X1.5 | M18X1.5 | M20X1.5 | 12 | 10 | 12 | 21.5 | 21.5 | 21.5 | 38 | 38 | 38 | 17 | 24 | 22 | 24 | |

| SAD-20-20-30 | M20X1.5 | M20X1.5 | M30X2 | 12 | 12 | 20 | 26.5 | 26.5 | 29.5 | 46 | 46 | 48 | 27 | 24 | 24 | 36 | |

| SAD-20-24-20 | M20X1.5 | M24X1.5 | M20X1.5 | 12 | 16 | 12 | 25.5 | 24.5 | 25.5 | 42 | 43 | 42 | 24 | 24 | 30 | 24 |

40

S |

| SAD-20-30-20 | M20X1.5 | M30X2 | M20X1.5 | 12 | 20 | 12 | 26.5 | 29.5 | 26.5 | 46 | 48 | 46 | 27 | 24 | 36 | 24 | |

| SAD-20-30-30 | M20X1.5 | M30X2 | M30X2 | 12 | 20 | 20 | 26.5 | 29.5 | 29.5 | 46 | 48 | 48 | 27 | 24 | 36 | 36 | |

| SAD-24- 14-24 | M24X1.5 | M14X1.5 | M24X1.5 | 16 | 6 | 16 | 24.5 | 26 | 24.5 | 43 | 41 | 43 | 24 | 30 | 17 | 30 | |

| SAD-24- 16-24 | M24X1.5 | M16X1.5 | M24X1.5 | 16 | 8 | 16 | 24.5 | 26 | 24.5 | 43 | 41 | 43 | 24 | 30 | 19 | 30 | |

| SAD-24- 18-24 | M24X1.5 | M18X1.5 | M24X1.5 | 16 | 10 | 16 | 24.5 | 25.5 | 24.5 | 43 | 42 | 43 | 24 | 30 | 22 | 30 | |

| SAD-24-20-24 | M24X1.5 | M20X1.5 | M24X1.5 | 16 | 12 | 16 | 24.5 | 25.5 | 24.5 | 43 | 42 | 43 | 24 | 30 | 24 | 30 | |

| SAD-24-30-24 | M24X1.5 | M30X2 | M24X1.5 | 16 | 20 | 16 | 28.5 | 26.5 | 28.5 | 47 | 48 | 47 | 27 | 30 | 36 | 30 | |

| SAD-30- 18-30 | M30X2 | M18X1.5 | M30X2 | 20 | 10 | 20 | 26.5 | 29.5 | 26.5 | 48 | 46 | 48 | 27 | 36 | 22 | 36 | |

| SAD-30-20-30 | M30X2 | M20X1.5 | M30X2 | 20 | 12 | 20 | 26.5 | 29.5 | 26.5 | 48 | 46 | 48 | 27 | 36 | 24 | 36 | |

| SAD-30-24-30 | M30X2 | M24X1.5 | M30X2 | 20 | 16 | 20 | 26.5 | 28.5 | 26.5 | 48 | 47 | 48 | 27 | 36 | 30 | 36 | |

| SAD-30-36-30 | M30X2 | M36X2 | M30X2 | 20 | 25 | 20 | 31.5 | 30 | 31.5 | 53 | 54 | 53 | 36 | 36 | 46 | 36 | |

| SAD-36-24-36 | M36X2 | M24X1.5 | M36X2 | 25 | 16 | 25 | 30 | 33.5 | 30 | 54 | 52 | 54 | 36 | 46 | 30 | 46 | |

| SAD-36-30-36 | M36X2 | M30X2 | M36X2 | 25 | 20 | 25 | 30 | 31.5 | 30 | 54 | 53 | 54 | 36 | 46 | 36 | 46 | |

| SAD-36-42-36S | M36X2 | M42X2 | M36X2 | 25 | 30 | 25 | 37 | 35.5 | 37 | 61 | 62 | 61 | 41 | 46 | 50 | 46 | |

| Note: In case if you are interested to order the adapter in complete set with cutting ring and nut ,it is necessary to insert the suffix "RN" after our part no . ,for example AC-26-26-30RN . |

|||||||||||||||||

The Equal Tees are high-quality hydraulic fittings designed to ensure reliable performance in various applications. They are specifically crafted for industrial, engineer truck, and agricultural machinery applications, catering to diverse needs.

These Equal Tees offer flexibility in working pressure, with options available at 3000PSI, 6000PSI, and 9000PSI. This versatility allows you to choose the suitable pressure rating for your specific hydraulic system requirements.

Constructed with top-grade materials, the Equal Tees are available in carbon steel or customizable stainless steel body options. This enables you to select the material that best suits your application's needs for strength and corrosion resistance.

The zinc-plated surface treatment provides enhanced durability and corrosion resistance, ensuring the longevity and performance of the Equal Tees even in challenging environments.

Sannke is renowned as the best hydraulic fitting factory, delivering top-notch quality and customer satisfaction. Contact us today to explore our extensive range of hydraulic fittings and discover the ideal solution for your hydraulic system needs.