DIN hydraulic fittings are designed to meet the highest standards of quality and performance in hydraulic systems. Our fittings are based on the installation design standard for 24 DEG METRICS FITTINGS, which is specified in ISO 12151-2. This standard ensures that our fittings are compatible with other fittings in hydraulic systems, allowing for seamless installation and use.

In addition to this standard, we also incorporate other design standards into our fittings, such as ISO 8434HE and DIN 2353, helping us to ensure that our fittings meet the highest standards of quality and reliability.

To ensure that our fittings provide a perfect match and replacement for Parker’s hose fittings, we have modeled our hydraulic core and sleeve after Parker’s 26 series, 43 series, 70 series, 71 series, 73 series, and 78 series. This allows our fittings to be used interchangeably with Parker’s hose fittings, providing greater flexibility and compatibility in hydraulic systems.

Our commitment to quality and performance is reflected in the design and construction of our DIN hydraulic fittings.

-

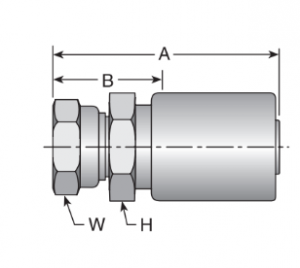

Female BSP Parallel Pipe – Swivel – (60° Cone) | Chromium-6 Free Plating

Female BSP Parallel Pipe – Swivel – (60° Cone) – permanent and crimp-style fitting for quick assembly with No-Skive hose compatibility. Chromium-6 free plating and ideal for use with hydraulic Braided Hoses.

-

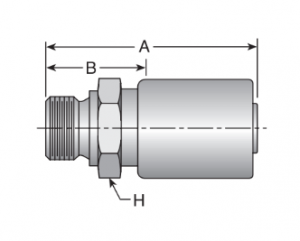

Male BSP Parallel Pipe – Rigid – (60° Cone) | Field-Attachable Convenience

Male BSP Parallel Pipe – Rigid – (60° Cone) – quick and tool-free hose assembly on-site. One-piece design reduces complexity and eliminate leakage.

-

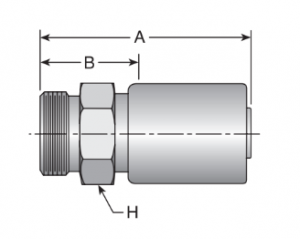

Male Standpipe Metric S – Rigid | Versatile Material Options

Male Standpipe Metric S – Rigid- compatible with 1SN, 2SN, R1AT, R2AT, 1SC, 2SC, R16, R17, 2ST, 1SK, 2SK, R3, R4, R6, R7, R8, 1TE, 2TE, and 3TE hoses. Adheres to ISO 8434-1-SDS standards.

-

Male Metric L – Rigid – (24° Cone) | Precision 24° Cone Design

Explore durable and efficient design to elevate your system with our Male Metric L – Rigid – (24° Cone). Precision-engineered for reliable performance.

-

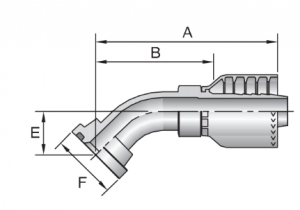

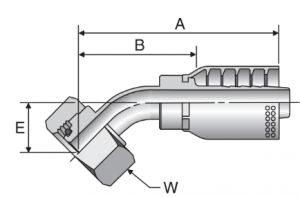

Female Metric S – Swivel – 45° Elbow – (24° Cone with O-Ring) | Optimized Swivel Design

Optimize your system with our Female Metric S – Swivel – 45° Elbow – (24° Cone with O-Ring). Precision design for seamless integration and efficient performance.

-

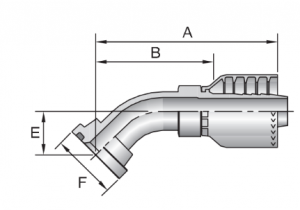

Female Metric S – Swivel – (24° Cone with O-Ring) | Crimp Attachment for Secure Connection

Enhance performance with our Female Metric S – Swivel – (24° Cone with O-Ring). Crimp attachment and versatile for various applications. Explore precision design now!

-

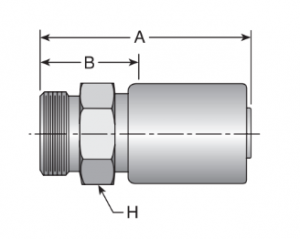

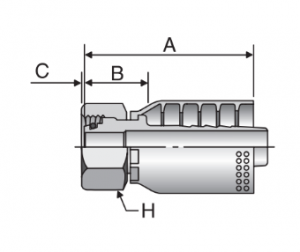

Male Metric S – Rigid – (24° Cone) | Zinc Plated for Corrosion Resistance

Upgrade with our Male Metric S – Rigid – (24° Cone). Crafted from steel, zinc-plated, and Cr(VI)-free for durable and reliable performance.

-

Female Metric L – Swivel – (24° Cone with O-Ring) | Swivel Functionality

Elevate your system with our Female Metric L – Swivel – (24° Cone with O-Ring). Precision design for seamless integration and reliable performance.

-

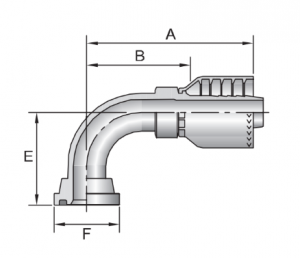

SAE Code 61 Flange Head – 90° Elbow | Standards Compliance

Optimize your hydraulic setup with our SAE Code 61 Flange Head – 90° Elbow. Versatile materials, NO-SKIVE design, and cost-saving advantages. Ideal for SAE100 R12 hoses.

-

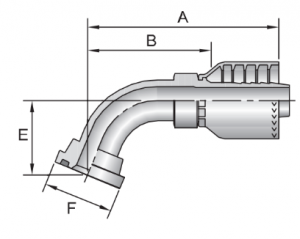

SAE Code 61 Flange Head – 67-1/2° Elbow | Optimized Fluid Flow

Enhance precision in your hydraulic system with our SAE Code 61 Flange Head – 67-1/2° Elbow. Quality design for optimal performance and durability.

-

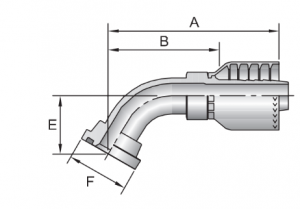

SAE Code 61 Flange Head – 60° Elbow | Precise Design / SAE Code 61 Standard

Explore durability with our SAE Code 61 Flange Head – 60° Elbow. Crafted from robust steel for lasting performance in your hydraulic system.

-

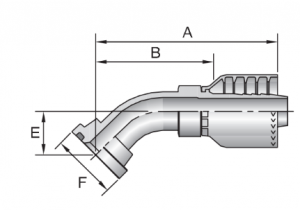

SAE Code 61 Flange Head – 45° Elbow | Precise Angle / Standards Compliance

Upgrade your system with our SAE Code 61 Flange Head – 45° Elbow. Versatile material options, NO-SKIVE design, and simple operation. Ideal for SAE100 R12 hoses.