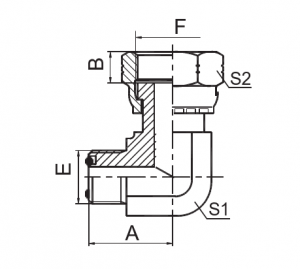

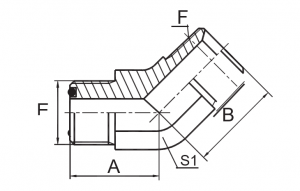

1. Designed for precise fluid direction changes. Its 90-degree angle ensures optimal flow control, enhancing the efficiency of your fluid system.

2. Select from a variety of protective finishes including zinc-plated, Zn-Ni-plated, Cr3, and Cr6-plated. These finishes not only enhance the fitting’s appearance but also provide exceptional corrosion resistance, extending its operational life.

3. Customize the fitting to match your specific application requirements with alternative materials like stainless steel, carbon steel, and brass. This versatility ensures compatibility with a wide range of fluids and environments, catering to diverse industries.

4. Its advanced O-ring seal technology guarantees leak-proof connections, making it an ideal choice for critical fluid applications.

5. From diverse finish options to material choices, this fitting meets stringent quality standards. Depend on a fitting that’s built for precision, performance, and durability, elevating the reliability of your fluid system.

|

PART NO.

|

THREAD | O-RING | DIMENSIONS | ||||

| E | F | E | A | B | S1 | S2 | |

| S2F9-04 | 9/16X18 | 9/16X18 | O011 | twenty three | 8.5 | 14 | 19 |

| S2F9-04-06 | 9/16X18 | 11/16″X16 | O011 | twenty three | 10 | 14 | twenty two |

| S2F9-06-04 | 11/16″X16 | 9/16X18 | O012 | 27.5 | 8.5 | 19 | 19 |

| S2F9-06 | 11/16″X16 | 11/16″X16 | O012 | 27.5 | 10 | 19 | twenty two |

| S2F9-06-08 | 11/16″X16 | 13/16″X16 | O012 | 27 | 11 | 19 | 27 |

| S2F9-08-06 | 13/16″X16 | 11/16″X16 | O014 | 31 | 10 | twenty two | twenty two |

| S2F9-08 | 13/16″X16 | 13/16″X16 | O014 | 31 | 11 | twenty two | 27 |

| S2F9-10-08 | 1″X14 | 13/16″X16 | O016 | 36.5 | 11 | 27 | 27 |

| S2F9-10 | 1″X14 | 1″X14 | O016 | 36.5 | 15 | 27 | 30 |

| S2F9-10-12 | 1″X14 | 1.3/16″X12 | O016 | 36.5 | 15 | 27 | 36 |

| S2F9-12 | 1.3/16″X12 | 1.3/16″X12 | O018 | 41 | 15 | 30 | 36 |

| S2F9-12-16 | 1.3/16″X12 | 1.7/16″X12 | O018 | 42.5 | 15 | 33 | 41 |

| S2F9-16-12 | 1.7/16″X12 | 1.3/16″X12 | O021 | 44.5 | 15 | 36 | 36 |

| S2F9-16 | 1.7/16″X12 | 1.7/16″X12 | O021 | 44.5 | 15 | 36 | 41 |

| S2F9-20 | 1.11/16″X12 | 1.11/16″X12 | O025 | 44.5 | 15 | 41 | 50 |

| S2F9-24 | 2″X12 | 2″X12 | O029 | 53.5 | 15 | 50 | 60 |

Enhance your fluid system’s efficiency with the meticulously crafted 90° Elbow ORFS Male O-Ring / ORFS Female fitting. Designed to facilitate precise fluid direction changes, its 90-degree angle is a testament to optimal flow control that propels your fluid system’s efficiency to new heights.

Engage in the freedom of choice with a spectrum of protective finishes including zinc-plated, Zn-Ni-plated, Cr3, and Cr6-plated options. Beyond their visual enhancement, these finishes are guardians of the fitting’s durability, providing unparalleled corrosion resistance and extending its operational life.

Personalize the fitting to harmonize with your distinct application requirements, choosing from alternative materials like stainless steel, carbon steel, and brass. This adaptability guarantees compatibility across a diverse range of fluids and environments, addressing the specific needs of various industries.

Rely on advanced O-ring seal technology that stands as a guarantee for leak-proof connections. This fitting is more than just a component—it’s a critical choice for fluid applications where reliability is paramount.

Every facet of this fitting, from its diverse finish options to the material choices, stands resolute in meeting stringent quality standards. Count on a fitting that’s precision-engineered, performance-driven, and built for enduring durability. Elevate the reliability of your fluid system with a fitting that’s a testament to Sannke’s commitment to excellence.

Discover hydraulic fitting mastery through Sannke, the epitome of distinction among hydraulic fitting factories. For inquiries and access to hydraulic solutions tailored to your exact needs, don’t hesitate to connect with us. Your journey toward optimized fluid system performance begins with Sannke.

-

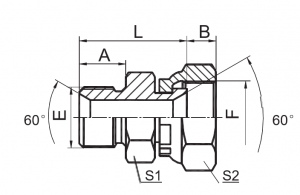

JIC Male / JIC Female Connectors | Versatile Fi...

-

BSP Male Captive Seal / BSP Female Fitting | Re...

-

ISO 6149-2 45° Elbow Metric Male 24°Cone | Metr...

-

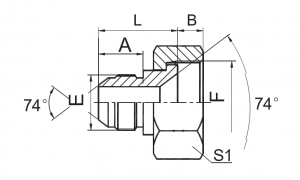

JIC Male 74° Cone / NPT Female Fittings | SAE J...

-

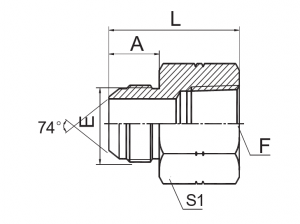

Long JIC Male 74° Cone / SAE O-Ring Boss L Seri...

-

45° Elbow ORFS Male O-Ring / NPT Male Fitting |...