1. Crafted from top-grade Stainless Steel (316SS / 304SS), Brass, and Aluminum for durability.

2. Designed for various pressure systems with threaded NPT, JIC, and BSP fittings.

3. Engineered to exceed industry standards, with plating that withstands over 96 hours of salt spray testing.

4. SAE J516 compliant, ensuring a secure connection for both high and low-pressure applications.

5. Perfect for tight spaces and complex setups, providing reliable performance in any scenario.

|

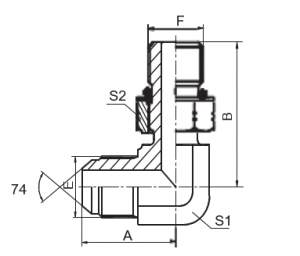

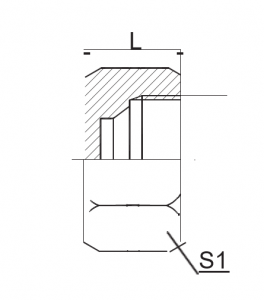

PART NO.

|

THREAD | DIMENSIONS | ||||

| E | F | A | B | S1 | S2 | |

| S2J9-02 | 5/16″X24 | 5/16″X24 | 21 | 5.6 | 11 | 12 |

| S2J9-03 | 3/8″X24 | 3/8″X24 | 22 | 5 | 11 | 14 |

| S2J9-04 | 7/16″X20 | 7/16″X20 | 24.5 | 9 | 11 | 15 |

| S2J9-05 | 1/2″X20 | 1/2″X20 | 26.5 | 9.5 | 14 | 17 |

| S2J9-06 | 9/16″X18 | 9/16″X18 | 26.9 | 10.5 | 14 | 19 |

| S2J9-06-08 | 9/16″X18 | 3/4″X16 | 28.5 | 11 | 16 | 24 |

| S2J9-08-06 | 3/4″X16 | 9/16″X18 | 32 | 10.5 | 19 | 19 |

| S2J9-08 | 3/4″X16 | 3/4″X16 | 32 | 11 | 19 | 24 |

| S2J9-08-10 | 3/4″X16 | 7/8″X14 | 32 | 13 | 19 | 27 |

| S2J9-10 | 7/8″X14 | 7/8″X14 | 37.8 | 13 | 22 | 27 |

| S2J9-10-08 | 7/8″X14 | 3/4″X16 | 37.8 | 11 | 22 | 24 |

| S2J9-10- 12 | 7/8″X14 | 1.1/16″X12 | 39.5 | 15 | 24 | 32 |

| S2J9-12 | 1.1/16″X12 | 1.1/16″X12 | 44.2 | 15 | 27 | 32 |

| S2J9-12-10 | 1.1/16″X12 | 7/8″X14 | 44.2 | 13 | 27 | 27 |

| S2J9-12-16 | 1.1/16″X12 | 1.5/16″X12 | 46 | 16 | 30 | 41 |

| S2J9-14 | 1.3/16″X12 | 1.3/16″X12 | 47.5 | 15 | 30 | 36 |

| S2J9-16 | 1.5/16″X12 | 1.5/16″X12 | 48.8 | 16 | 33 | 41 |

| S2J9-16-20 | 1.5/16″X12 | 1.5/8″X12 | 54 | 17 | 41 | 50 |

| S2J9-20-16 | 1.5/8″X12 | 1.5/16″X12 | 55.5 | 16 | 41 | 41 |

| S2J9-20 | 1.5/8″X12 | 1.5/8″X12 | 55.5 | 17 | 41 | 50 |

| S2J9-20-24 | 1.5/8″X12 | 1.7/8″X12 | 59.5 | 20 | 48 | 55 |

| S2J9-24-20 | 1.7/8″X12 | 1.5/8″X12 | 62.5 | 17 | 48 | 50 |

| S2J9-24 | 1.7/8″X12 | 1.7/8″X12 | 62.5 | 20 | 48 | 55 |

| S2J9-32 | 2.1/2″X12 | 2.1/2″X12 | 75.5 | 24.5 | 63 | 75 |

| Note: Nut and sleeve should be ordered separately. The nut NB200 and sleeve NB500 is suitable for metric tube, the nut NB200 and sleeve NB300 is suitable for inch tube. | ||||||

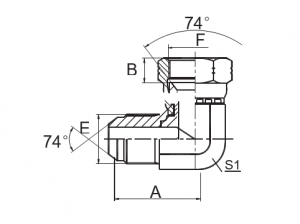

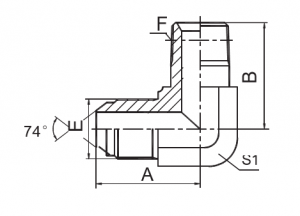

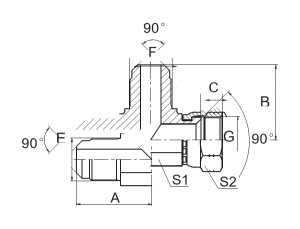

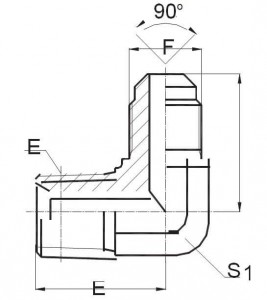

90° ELBOW JIC MALE 74°CONE / JIC FEMALE 74° SEAT Hydraulic Fitting, a pinnacle of durability and adaptability for your hydraulic systems.

Crafted from the finest materials, including top-grade Stainless Steel (316SS / 304SS), Brass, and Aluminum, this fitting guarantees exceptional longevity. Its robust construction ensures reliable performance, maintaining the integrity of your hydraulic setup over time.

Versatility is at the core of this fitting’s design. Engineered to accommodate various pressure systems, it boasts compatibility with threaded NPT, JIC, and BSP fittings. This adaptability makes it a versatile choice for a wide range of hydraulic applications.

Quality shines through in every aspect of this fitting. It not only meets but exceeds industry standards, showcasing plating that can withstand over 96 hours of salt spray testing. This level of resilience ensures a corrosion-resistant solution that stands strong against challenging environments.

Compliance with SAE J516 standards ensures a secure connection, making it suitable for both high and low-pressure applications. Whether your needs demand precision or power, this fitting delivers reliable performance in any scenario.

Navigating tight spaces and complex setups becomes effortless with the 90° ELBOW JIC MALE 74°CONE / JIC FEMALE 74° SEAT Hydraulic Fitting. Its design is optimized to fit seamlessly into challenging configurations, providing a dependable solution that adapts to your requirements.

Elevate your hydraulic systems with excellence. As a premier hydraulic fitting factory, Sannke is your partner for top-notch solutions. Contact us today to discover how our expertise can enhance your hydraulic setup.