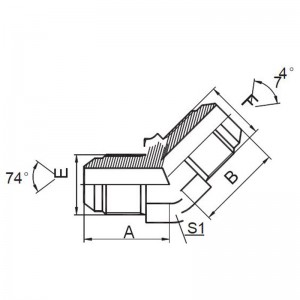

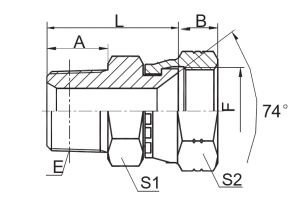

1. 45° Elbow JIC Male 74° Cone fitting provides a secure and reliable connection for hydraulic systems.

2. Rated to work under pressures up to 9000 psi, making them suitable for demanding applications.

3. Available in various materials and configurations to meet specific application needs.

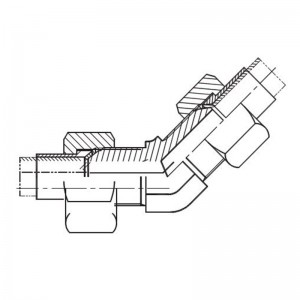

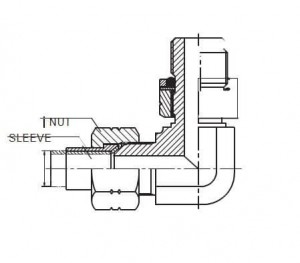

4. Precision-machined components ensure perfect deformation of ferrules and tubing connections, creating leak-free connections

5. Hardened threads and smoothed surface finishes extend fitting life by preventing sticky matching threads, while radius junction designs with elbows allow a smooth flow path.

|

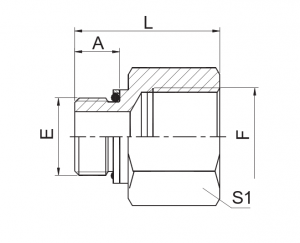

PART NO.

|

THREAD | DIMENSIONS | |||

| E | F | A | B | S1 | |

| S1J4-04 | 7/16″X20 | 7/16″X20 | 21.5 | 21.5 | 11 |

| S1J4-05 | 1/2″X20 | 1/2″X20 | 23 | 23 | 14 |

| S1J4-06 | 9/16″X18 | 9/ 16″X18 | 22.8 | 22.8 | 14 |

| S1J4-08 | 3/4″X16 | 3/4″X16 | 26.8 | 26.8 | 19 |

| S1J4-10 | 7/8″X14 | 7/8″X14 | 31 | 31 | 22 |

| S1J4-12 | 1.1/16″X12 | 1.1/16″X12 | 35.5 | 35.5 | 27 |

| S1J4-16 | 1.5/16″X12 | 1.5/16″X12 | 38.5 | 38.5 | 33 |

| NB200, NB300. Note Nut and sleeve should be ordered separately. The nut NB200 and sleeve NB500 are suitable for metric tubes, the nut NB200 and sleeve NB300 are suitable for inch tubes. | |||||

Our 45° Elbow JIC Male 74° Cone fittings, designed to provide secure and reliable connections in hydraulic systems. These fittings offer a range of features and benefits that make them an excellent choice for various applications.

With a working pressure rating of up to 9000 psi, our 45° Elbow JIC Male 74° Cone fittings are engineered to withstand high-pressure environments, ensuring optimal performance even in demanding applications. Additionally, they have a wide working temperature range of -20 to 200 degrees Celsius, allowing them to operate effectively in diverse temperature conditions.

Our fittings come in diverse materials and configurations, allowing you to choose the option that best suits your specific requirements. Whether you need fittings made from stainless steel, carbon steel, or other materials, we have you covered.

Precision-machined components are a key feature of our fittings. They ensure perfect deformation of ferrules and tubing connections, resulting in reliable, leak-free joints. This precision machining guarantees the integrity of your hydraulic system, providing peace of mind and optimal performance.

To enhance durability and prevent sticking of matching threads, our fittings feature hardened threads and smoothed surface finishes. This extends the fitting’s life span and promotes ease of installation and disassembly, saving you time and effort during maintenance and repairs.

The radius junction design with elbows in our fittings ensures a smooth flow path, minimizing pressure drops and promoting efficient fluid transfer within the hydraulic system. This design feature contributes to overall system performance and reliability.

For ease of identification, each fitting is stamped with size, material, and heat code information. This ensures proper selection and traceability for quality control and maintenance purposes.

Our 45° Elbow JIC Male 74° Cone fittings are designed for easy disconnection and retightening, allowing for convenient installation, maintenance, and system modifications.

Choose Sannke as your trusted hydraulic fitting factory. We prioritize quality, reliability, and customer satisfaction. Contact us today to learn more about our fittings and how they can meet your hydraulic connection needs.